Heated Hardwood Floors on Concrete: Top 3 Powerful Benefits 2025

The Warm Revolution Underfoot

Heated hardwood floors on concrete provide the perfect combination of luxury and practicality for homeowners seeking both beauty and comfort in their flooring solutions. If you’re looking to install this system in your home, here’s what you need to know:

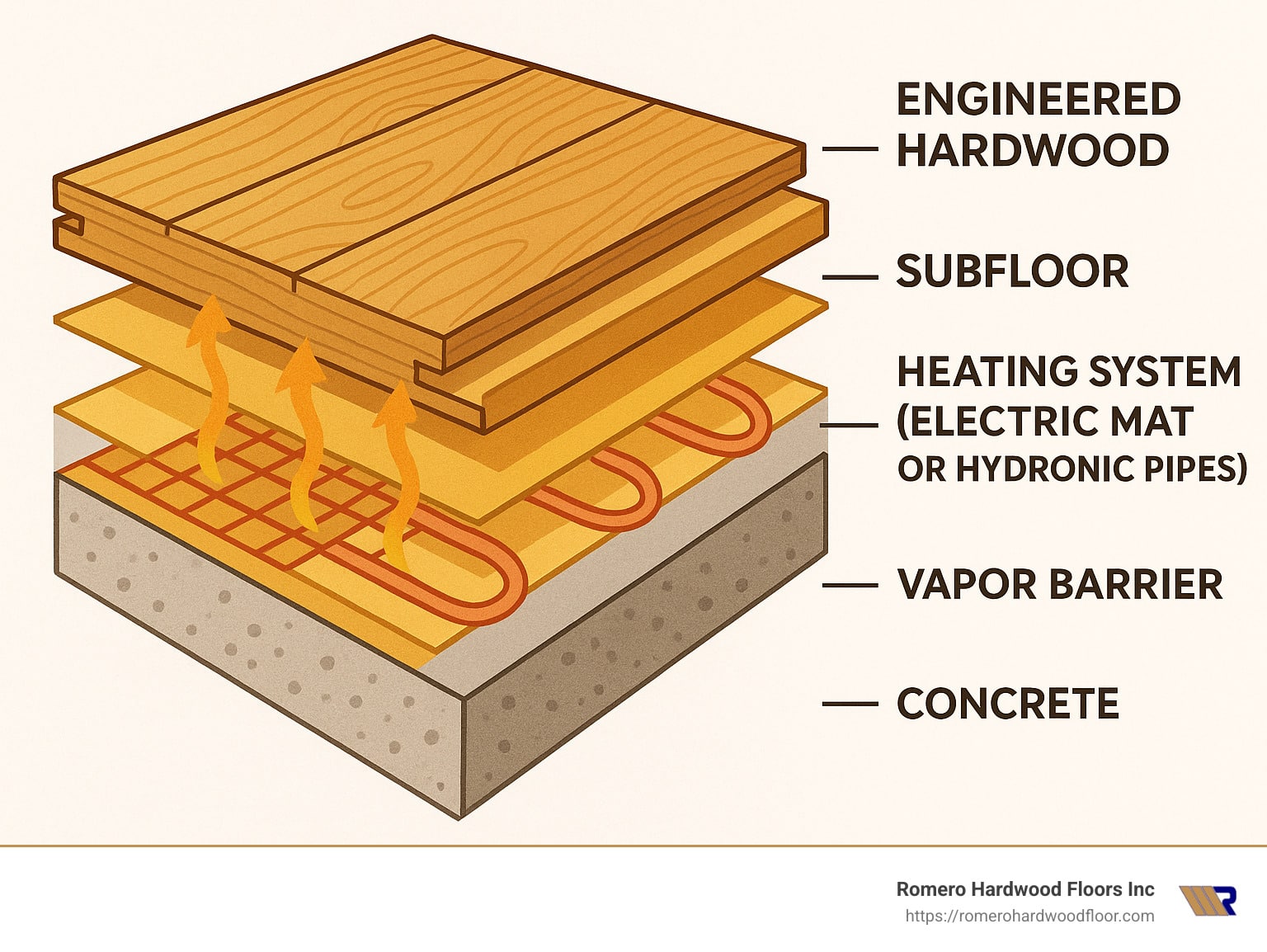

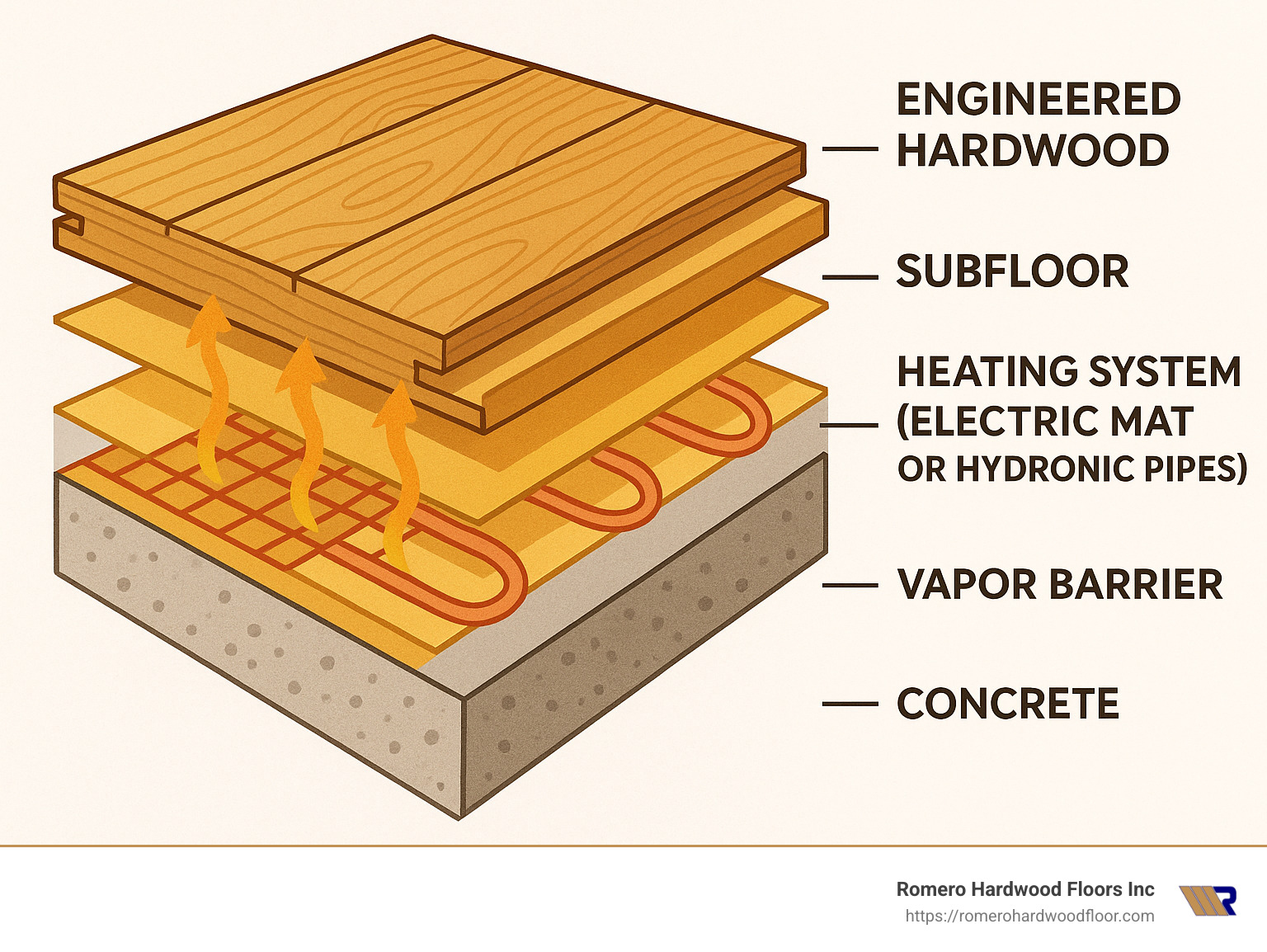

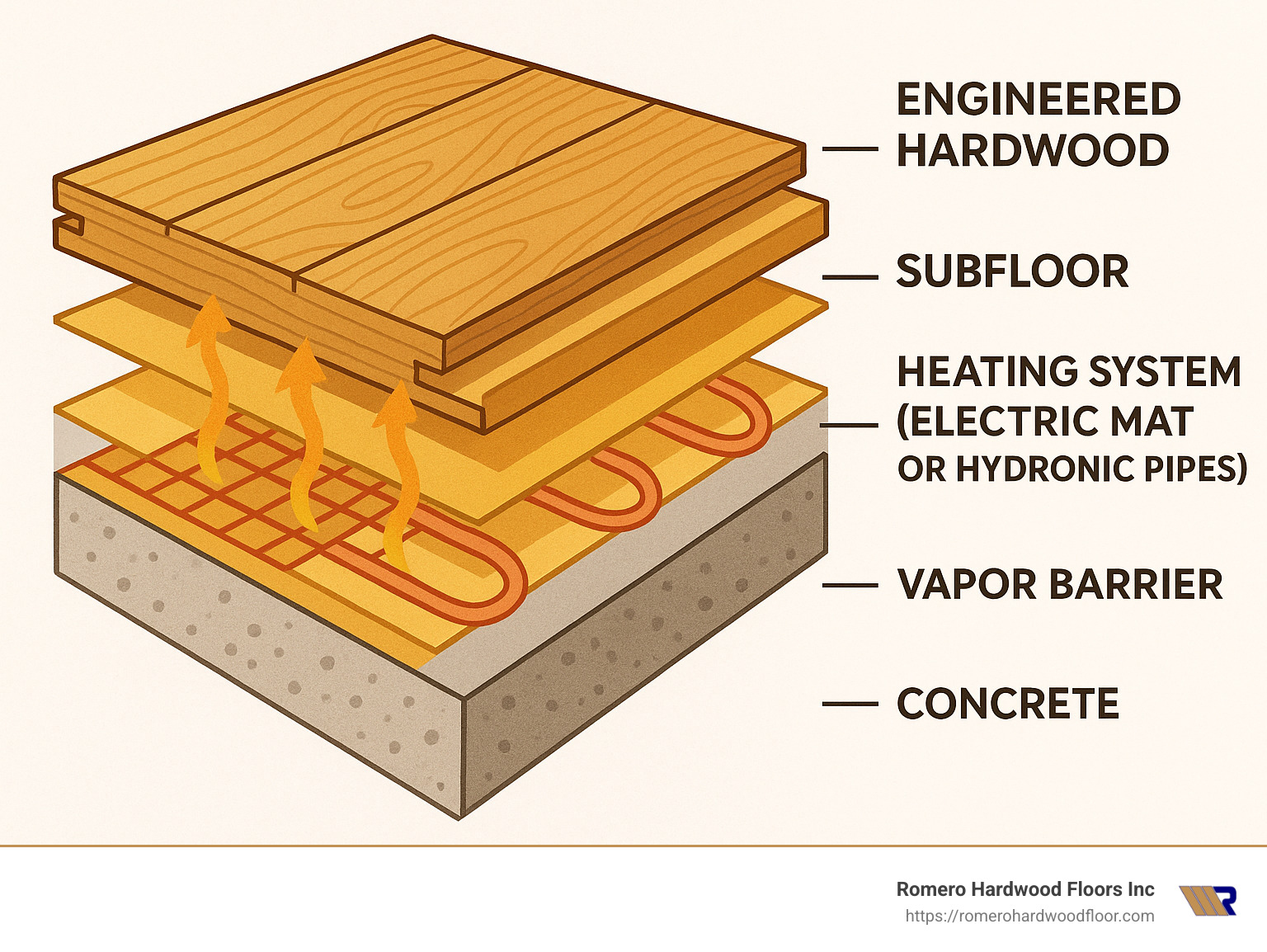

Quick Installation Guide for Heated Hardwood Floors on Concrete:

- Choose the right wood: Engineered hardwood is most suitable (avoid maple and Brazilian cherry)

- Ensure proper concrete preparation: Allow 60-90 days for new concrete to cure

- Select your heating system: Hydronic (water-based) or electric (mat/cable)

- Install moisture barrier: Critical for concrete subfloors

- Use appropriate installation method: Floating installation is safest and most reliable

- Maintain temperature limits: Keep surface temperature below 80°F (27°C)

The marriage of radiant heating with hardwood flooring creates an unparalleled underfoot experience. While traditional forced-air heating systems blow warm air around a room, radiant floor heating warms you from the ground up, providing consistent, comfortable heat without the noise or allergen circulation of conventional systems.

Installing heated hardwood floors on concrete presents some unique challenges. Concrete slabs act as thermal masses that store and slowly release heat, making them excellent candidates for radiant systems. However, the natural properties of wood – its tendency to expand, contract, and respond to moisture – require careful planning and proper installation techniques.

I’m Francisco Romero, owner of Romero Hardwood Floors Inc., and over my 15+ years in the hardwood flooring industry, I’ve installed hundreds of heated hardwood floors on concrete slabs throughout Massachusetts, helping homeowners transform cold concrete surfaces into warm, inviting living spaces.

Heated hardwood floors on concrete terms to learn:

– floating wood floor over concrete

– how to install floating engineered hardwood flooring on concrete

– installing hardwood floors on concrete slab

Radiant Heat Meets Concrete: How the System Works

When you step onto a warm wood floor on a chilly winter morning, there’s something almost magical about the cozy comfort beneath your feet. But behind that simple pleasure lies some fascinating engineering. Let me walk you through how heated hardwood floors on concrete actually work.

Two main types of systems bring warmth to your floors: hydronic and electric. Each has its own personality, so to speak.

Hydronic systems are like the marathon runners of radiant heat. They circulate warm water through a network of PEX tubing (that’s cross-linked polyethylene, if you’re curious) that’s either embedded directly in your concrete slab or attached to its surface. A boiler heats the water, which then radiates that wonderful warmth up through your floors. While these systems cost more upfront, they’re more economical to operate long-term – perfect if you’re heating larger areas of your home.

“Demand for in-floor radiant heat has grown dramatically over the last 25 years,” notes industry expert Jeff Hosking. “Early hydronic systems were temperamental and costly, but modern systems are reliable and affordable.”

Electric systems, on the other hand, are more like sprinters – quicker to install and perfect for smaller spaces. These use electric resistance cables or mats laid directly on your concrete slab. While installation is typically less expensive, your monthly energy bills might be higher than with hydronic systems. They’re ideal for warming up that chilly bathroom or kitchen.

Your concrete slab plays a starring role in this heating performance. As Jeff Brickman, a flooring consultant, explains: “Radiant heat takes 3-5 days to get to temperature in a concrete slab. It’s a slow process.” This is because concrete has significant thermal mass – it absorbs heat energy slowly but also releases it gradually, creating a steady, comfortable warmth.

One quirk of radiant systems is something called “striping,” where you might feel warmer spots directly above heating tubes and cooler areas between them. Modern installations solve this through proper tube spacing and using materials like aluminum heat transfer plates or self-leveling compounds to distribute heat evenly across your floor.

Why Concrete Loves Radiant Heat

Concrete and radiant heating go together like bread and butter. Here’s why they’re such perfect partners:

Concrete is an excellent thermal conductor, efficiently transferring heat from your system up into your living space. Once warmed up, your concrete slab becomes a giant thermal battery, storing heat and continuing to radiate warmth even when the system cycles off. This creates remarkably stable temperatures and helps keep your energy bills in check.

The dense mass of concrete also distributes heat evenly throughout your space, eliminating those annoying hot and cold spots you might get with forced-air systems. And if your power goes out briefly during winter? No worries – your warm concrete slab will maintain temperature much longer than other heating systems.

For the best performance, we always recommend proper insulation beneath and around your concrete slab. Without it, you’re paying to heat the earth below your home rather than your living space above it!

Challenges When Wood Enters the Picture

Now, while concrete and radiant heat are best friends, adding hardwood to the mix creates some interesting challenges.

Wood is hygroscopic – a fancy word meaning it naturally absorbs and releases moisture based on its environment. When heated from below, wood can lose moisture and shrink, potentially leading to problems like cupping (where board edges rise higher than centers), gapping between planks, or even cracking if the temperature fluctuations are extreme.

As one flooring expert puts it, “Wood shrinks as it loses moisture and swells when it picks up moisture.” This natural behavior means we need to be thoughtful about how we install heated hardwood floors on concrete.

“The surface temperature of the subfloor should not exceed 80 degrees,” advises Jeff Hosking. “I DO NOT RECOMMEND GLUING DOWN ANY FLOORING DIRECTLY TO THE EXPOSED RADIANT HEAT PIPING.”

At Romero Hardwood Floors, we’ve seen these challenges firsthand. Just last year, we were called to a home in Revere where solid oak planks had been installed directly over radiant-heated concrete without proper moisture barriers. Within a single heating season, the beautiful floors had cupped severely and developed unsightly cracks.

The good news? With proper planning, material selection, and installation techniques (which we’ll cover in upcoming sections), these problems are completely avoidable. We’ve installed hundreds of successful heated hardwood floors on concrete throughout Massachusetts, creating warm, beautiful spaces that stand the test of time.

The science behind radiant heating actually dates back thousands of years – the ancient Romans used a similar concept called hypocaust to heat their bathhouses. Today’s systems are far more sophisticated, but the fundamental principle remains the same: gentle, consistent heat rising from below creates the most natural and comfortable warmth possible. According to the Scientific research on radiant heating history, this method of heating is not just comfortable, but can be up to 30% more efficient than forced-air systems.

Choosing Hardwood That Thrives on Radiant-Heated Concrete

Let’s talk about finding the perfect wood flooring for your warm floors. When it comes to heated hardwood floors on concrete, not all wood options will give you that beautiful, long-lasting result you’re dreaming of. It’s a bit like finding the right dance partner – you need wood that can gracefully handle the heat without throwing a tantrum!

The stability of your chosen wood species makes all the difference. Think of stability as your wood’s ability to stay cool under pressure (or in this case, under heat). Wood species have different stability coefficients – fancy numbers that tell us how much they’ll move when conditions change. The lower this number, the happier your wood will be with radiant heat.

For example, mesquite is incredibly stable with a tiny coefficient of 0.00129, while red oak comes in at 0.00369 – still acceptable but more likely to shift. Some woods just can’t handle the heat – maple and Brazilian cherry (Jatoba) tend to be drama queens with radiant systems and are best avoided.

Size matters too! Narrower boards (3″ or less) generally perform better than their wider cousins. Those gorgeous wide planks you’ve been eyeing? They’re still possible, but you’ll definitely want to go with engineered construction to keep them looking beautiful year after year.

Engineered vs. Solid vs. Laminate: What Really Works?

When installing heated hardwood floors on concrete, your flooring choice is probably the most critical decision you’ll make. Let me break down the contenders:

| Flooring Type | Radiant Heat Compatibility | Dimensional Stability | Typical Warranty Coverage | Maximum Surface Temp |

|---|---|---|---|---|

| Engineered Hardwood | Excellent | High (up to 70% more stable than solid) | Most manufacturers provide coverage | 80-85°F (27-29°C) |

| Solid Hardwood | Limited | Low to moderate (species-dependent) | Generally not warranted | 80°F (27°C) max |

| Laminate | Good | High | Most manufacturers provide coverage | 80-85°F (27-29°C) |

| Luxury Vinyl Plank | Excellent | Very high | Full coverage with most brands | 85°F (29°C) |

Engineered Hardwood is truly the champion for heated hardwood floors on concrete. Think of it as the superhero version of wood flooring – it has a real wood top layer (so you get that genuine beauty) bonded to multiple layers of plywood or high-density fiberboard underneath. This clever construction makes it up to 70% more stable than solid hardwood.

The secret lies in those cross-layered lower plies, which fight against the warping and cupping that can plague solid wood when it gets warm. Most engineered floors can be installed as floating systems, where the boards lock together and move as one big happy family, further reducing the chance of gaps appearing between boards.

Solid Hardwood is like that friend who just can’t handle temperature changes – a bit high-maintenance for radiant heat systems. While it’s technically possible to use solid wood, most manufacturers won’t warranty it over radiant heat, especially on concrete slabs. The risk of warping, splitting, or cracking is just too high.

If your heart is set on solid wood, look for quartersawn cuts (more stable than plainsawn) and stick with narrower boards under 3″ wide. You’ll also need to be extremely diligent about maintaining consistent indoor humidity levels – no small task in many climates!

Laminate and Luxury Vinyl Plank (LVP) are the practical alternatives that have come a long way in mimicking real wood. Both handle heat beautifully, and most manufacturers happily warranty them for use over radiant systems. While they might not have that authentic wood feel underfoot, they offer budget-friendly, low-maintenance options that look surprisingly realistic.

Recommended Wood Species & Formats

After installing hundreds of heated hardwood floors on concrete throughout Massachusetts, we at Romero Hardwood Floors have definitely developed some favorites:

When it comes to engineered wood, white oak (especially quartersawn) is our most recommended option. It’s naturally stable, takes stain beautifully, and has a timeless appeal that works in almost any home. Hickory is another excellent choice, offering exceptional hardness along with good heat tolerance. Walnut and ash round out our top picks, both providing gorgeous aesthetics with the stability needed for radiant systems.

For something a little different, strand-woven bamboo is worth considering. It’s incredibly stable – sometimes even more so than engineered hardwood – and offers excellent sustainability credentials. Luxury vinyl plank has also won over many of our clients who wanted a waterproof, worry-free option that still captures the look of real wood.

We generally steer clients away from maple (especially in wider planks), Brazilian cherry/Jatoba, American beech, and most exotic hardwoods. These species tend to be more temperamental when subjected to the warming and cooling cycles of radiant heat.

When shopping for engineered hardwood, look for quality markers like 5-7 ply construction (more plies generally equals more stability) and cross-layered plywood cores, which outperform HDF cores in most radiant applications. A thicker wear layer (3mm or greater) will give you more refinishing options down the road, and matte or low-gloss finishes tend to show fewer imperfections over time.

“I was absolutely set on wide-plank maple floors until Francisco explained why that wouldn’t work well with our new radiant heating system,” shares one of our Revere clients. “We ended up with engineered white oak instead, and three years later, they still look perfect – no gaps, no cupping, just warm, beautiful floors.”

For a deeper dive into why engineered hardwood makes so much sense, especially with radiant heat, check out our detailed guide: Engineered Hardwood Benefits

The right wood choice sets the foundation for years of cozy, problem-free enjoyment of your heated hardwood floors on concrete. Choose wisely, and you’ll enjoy the best of both worlds: the timeless beauty of wood with the luxurious comfort of radiant heat.

Installing Heated Hardwood Floors on Concrete: Step-by-Step

Installing heated hardwood floors on concrete is like baking a perfect soufflé – it requires patience, precision, and the right techniques. At Romero Hardwood Floors, we’ve refined our installation process over thousands of projects to ensure your floors not only look beautiful but perform flawlessly for decades to come.

Pre-Installation Checklist & Acclimation

Before we bring a single plank into your home, your concrete slab needs proper preparation. Think of this as creating the perfect foundation for your investment.

New concrete slabs are particularly tricky – they need to cure for 60-90 days minimum before we can even think about installing wood flooring. Rushing this crucial step is like trying to frost a cake that’s still warm – disaster waiting to happen.

Once the slab has properly cured, we conduct thorough moisture testing following the ASTM F-2170 standard. This isn’t just a surface test – we actually drill small holes in your concrete, insert special probes, and measure the internal moisture levels. For heated hardwood floors on concrete to succeed, we need to see internal relative humidity readings below 75%.

“The biggest mistake I see homeowners make is skipping proper moisture testing,” says Francisco Romero. “That hidden moisture will find its way out eventually, and by then, it’s too late for your beautiful floors.”

We also carefully check your slab for flatness – it must be within 3/16″ over a 10-foot radius. Any high spots get ground down, and low areas filled with self-leveling compound. This creates the smooth, even surface your hardwood needs.

For homes with hydronic heating systems, we’ll run your system for at least 72 hours at normal operating temperature before bringing in your flooring. This stabilizes the concrete and lets us identify any potential issues with the heating system before your beautiful new floors go down.

The acclimation process is equally critical. We’ll deliver your flooring materials 3-7 days before installation, then carefully “sticker-stack” them by removing boards from boxes and placing small wood spacers between layers. This allows air to circulate around each board, helping them adjust to your home’s specific conditions.

During this acclimation period, we maintain your home at normal living temperatures (65-75°F) with relative humidity between 35-50%. Your radiant system should be running at its normal operating temperature – not cranked up high, not turned off.

Underlayments & Vapor Control

Even properly cured concrete continuously releases moisture vapor – it’s just the nature of the material. Without proper protection, this invisible enemy will wreak havoc on your heated hardwood floors on concrete.

For floating installations (our most recommended method), we start with a minimum 6-mil polyethylene vapor barrier. We overlap seams by at least 6 inches and seal them with waterproof tape, creating an unbroken moisture shield between your concrete and wood flooring.

Many homeowners appreciate our combination underlayments, which merge vapor protection with sound-dampening properties. These products simplify installation while reducing footfall noise – particularly valuable in multi-story homes or condominiums.

For glue-down installations, standard adhesives simply won’t cut it. We use specialized moisture-mitigating adhesives like Bostik’s MVP4 or Sika’s MB that simultaneously bond your flooring and block moisture vapor. In extreme cases, we might recommend applying a separate moisture membrane before the adhesive layer for extra protection.

Some situations call for a nail-assist installation, where we install a plywood subfloor over your concrete. Here, we place a vapor barrier beneath the plywood and use special concrete-compatible fasteners that won’t damage your radiant heating system.

You can learn more about underlayment options on our detailed guide: Hardwood Floor Underlayment Types

Hydronic vs. Electric Systems: Flooring Implications

Your choice of radiant heating system significantly impacts how we approach your flooring installation.

Hydronic systems, with their PEX tubing embedded in concrete, create a high thermal mass that changes temperature gradually. This slow, gentle heating and cooling cycle puts less stress on your wood flooring. These systems typically operate with water temperatures around 100-120°F, resulting in surface temperatures of about 75-80°F – perfect for wood flooring comfort without damage.

The gradual nature of hydronic systems gives us flexibility – we can use floating, glue-down, or nail-assist installation methods with proper moisture barriers in place.

Electric systems (using heating mats or cables) respond more quickly, heating up and cooling down faster than their hydronic counterparts. This rapid temperature change requires extra care, which is why we typically recommend floating installations for electric systems. The floating method allows your floor to move slightly as a unit, accommodating these quicker temperature shifts.

“I’ve seen beautiful hardwood floors ruined because someone installed an electric system with too much power output,” Francisco notes. “For wood flooring, we ensure electric systems never exceed 15 watts per square foot.”

For both system types, in-floor temperature sensors are absolutely essential. Unlike air sensors, these directly monitor your floor’s surface temperature, preventing overheating that could damage your wood. We carefully position these sensors between heating elements for the most accurate readings.

Before installation begins, we carefully mark the location of all heating elements. This creates a safety map that prevents accidental damage during the flooring installation process.

As industry expert Jeff Hosking emphatically states, “I DO NOT RECOMMEND GLUING DOWN ANY FLOORING DIRECTLY TO THE EXPOSED RADIANT HEAT PIPING.” This wisdom explains why floating installations are our preferred method – they eliminate the risk of damaging heating elements with fasteners or adhesives.

For more detailed information about installing radiant heat systems under wood floors, check out this helpful resource: Installing Radiant Heat Under Wood Floors

When properly installed, your heated hardwood floors on concrete will provide decades of comfortable, beautiful service. The key is working with experienced professionals who understand the unique challenges of this specialized installation process.

Moisture, Temperature & Humidity Management for Longevity

Living with heated hardwood floors on concrete is a bit like maintaining a relationship – it requires attention, care, and understanding of your partner’s needs. At Romero Hardwood Floors, we’ve seen beautiful installations last for decades, and others fail within months. The difference? Almost always comes down to how well homeowners manage the delicate balance of moisture, temperature, and humidity.

Your wood flooring is constantly responding to its environment, even when you can’t see it happening. Think of wood as a living, breathing material that expands and contracts with changes in its surroundings. When we install heated hardwood floors on concrete, we’re creating a system that needs thoughtful management.

“The surface temperature of the subfloor should not exceed 80 degrees,” warns industry expert Jeff Hosking, and this advice is golden. Pushing your floor heating beyond this 80°F (27°C) threshold dramatically increases the risk of damaging your beautiful wood floors. This is why we always recommend floor-sensing thermostats rather than those that only measure air temperature – they give you precise control over what’s happening at the surface level.

Temperature changes should be gradual, like a slow sunrise rather than flipping on a light switch. Program your system for incremental adjustments of no more than 5°F per day when raising or lowering temperatures. Your wood will thank you by maintaining its shape and integrity. Many of our clients are surprised to learn that dramatic day/night temperature setbacks can actually be more harmful than maintaining consistent temperatures.

Humidity management goes hand-in-hand with temperature control. The sweet spot for heated hardwood floors on concrete is maintaining indoor relative humidity between 35-50% year-round. During the heating season, when indoor air naturally becomes drier, a whole-house humidifier can be your floor’s best friend. Conversely, in humid summer months, dehumidifiers help prevent the wood from absorbing excess moisture.

“I remember installing gorgeous engineered oak floors for a family in Winchester,” shares Francisco Romero. “They called me in a panic the following winter when gaps started appearing between the boards. After checking their home, we finded their humidity had dropped to 22% – far too dry. Once we installed a proper humidifier, the floors stabilized beautifully.”

For homeowners who want to take monitoring to the next level, we often recommend Fidbox data loggers. These small devices install beneath your flooring and continuously track temperature and humidity conditions. The data can be retrieved wirelessly, giving you insights into what’s happening under your feet. They’re particularly valuable for high-end installations or homes that are frequently vacant.

In a recent Swampscott installation, Fidbox monitors beneath an engineered white oak floor over hydronic-heated concrete proved invaluable. When the homeowners returned from a winter vacation to find minor gapping, the Fidbox data revealed that their house-sitter had completely turned off the heat, then rapidly reheated the home. This information allowed us to address the cause rather than just treating the symptom.

Preventing Cupping, Gapping, and Cracking

The three horsemen of hardwood floor apocalypse – cupping, gapping, and cracking – can all be prevented with proper care of your heated hardwood floors on concrete.

Cupping occurs when the edges of boards become higher than their centers, creating a washboard effect. This typically happens when the bottom of the wood absorbs more moisture than the top. Preventing cupping starts with proper installation (including moisture barriers) but continues with consistent humidity management. Engineered hardwood with balanced construction is naturally more resistant to cupping, especially when you choose species with low movement coefficients.

Gapping between boards is often seasonal and most noticeable during heating season when indoor air becomes drier. While some minimal seasonal movement is normal and unavoidable, excessive gaps can be prevented by selecting narrower boards (under 5″ wide) and engineered products with cross-layered construction. Many of our clients find that maintaining winter humidity with whole-house humidifiers makes a tremendous difference. As a design tip, matte finishes tend to make any small gaps less noticeable than high-gloss floors.

Cracking or splitting of individual planks usually indicates stress from rapid dimensional changes. “Hairline cracks running down the middle of boards often appear when radiant heat is first activated,” notes one flooring expert. “This typically happens because the wood hasn’t been properly acclimated or the heat was increased too rapidly.”

One of our most successful installations was in Medford, where we instructed the homeowners to increase their system temperature by just 2°F per day over the first week after installation. This slow, gentle approach completely eliminated the cracking issues they’d experienced with a previous installation. Floating installations also help prevent cracking by allowing the floor to move slightly as a unified system.

For all these concerns, selecting quartersawn or rift-sawn wood when possible provides additional stability, as these cutting methods create boards that are naturally more resistant to dimensional changes.

Warranty & Documentation Best Practices

The paperwork might not be exciting, but proper documentation can save you thousands of dollars and countless headaches if problems arise with your heated hardwood floors on concrete.

Start by obtaining and carefully following all manufacturer guidelines for both your flooring and heating system. Keep these documents with your home records – they’re as important as your deed when it comes to protecting your investment. Most engineered floating flooring manufacturers warranty installations over hydronic heat, with exceptions for unstable species like maple and Brazilian cherry.

Temperature logs, especially during the initial break-in period, demonstrate that you’ve maintained appropriate conditions. Similarly, keep records of all moisture tests performed on your concrete slab before installation – these baseline measurements can be invaluable if questions arise later.

We always recommend taking photos during each phase of installation, particularly of moisture barriers and underlayments before they’re covered. These hidden elements are impossible to inspect later without damaging your floor, so photographic evidence of proper installation can be crucial for warranty claims.

At Romero Hardwood Floors, we provide all clients with comprehensive documentation packages that include moisture test results, installation photos, manufacturer warranties, and maintenance guidelines. This might seem excessive, but we’ve seen these documents save homeowners thousands of dollars when addressing warranty issues.

Beautiful heated hardwood floors on concrete are an investment in your home’s comfort and value. Taking the time to understand and manage your floor’s environment pays dividends in longevity and performance. As we like to tell our clients – an ounce of humidity control is worth a pound of floor repairs!

For more information about engineered wood with underfloor heating, visit: Engineered Wood with Underfloor Heating

Costs, Energy Savings & Long-Term Value

When homeowners ask me about heated hardwood floors on concrete, one of the first questions is almost always about cost. It’s a significant investment, but one that pays dividends in comfort, efficiency, and home value for years to come.

Installing these systems isn’t inexpensive, but the range of options means there’s usually a solution for most budgets. Based on internet data (not actual costs for Romero Hardwood Floors), you can expect to invest between $12-$40 per square foot for a complete installation, with premium systems potentially reaching $60 per square foot or more.

What drives these costs? The heating system itself typically accounts for $6-$20 per square foot, with hydronic systems generally commanding higher upfront costs than electric alternatives. Your choice of engineered hardwood adds another $4-$12 per square foot, while professional installation labor ranges from $2-$8 per square foot. Don’t forget to budget for necessary subfloor preparation, moisture barriers, and other accessories, which can add anywhere from a nominal amount to $20 per square foot for challenging situations.

“Many homeowners are surprised to learn how quickly these systems can pay for themselves through energy savings,” I often tell my clients. Radiant heating systems typically use 10-30% less energy than traditional forced-air systems. This efficiency comes from several inherent advantages of radiant heat.

For one, these systems maintain comfort at lower overall temperatures – you simply don’t need the air as warm when your feet are cozy. There’s also no heat loss through ductwork, which typically wastes 25-40% of energy in forced-air systems. The concrete slab itself becomes a thermal battery, storing heat and continuing to warm your space even during system off-cycles. Many of our Massachusetts clients also appreciate the ability to zone their heating, warming only the rooms they’re actively using.

Beyond the monthly energy savings, heated hardwood floors on concrete add substantial value to your home. Real estate professionals typically estimate that these systems return 50-80% of their installation cost in added home value. I’ve seen this throughout Massachusetts – homes with radiant heated floors simply sell faster and command premium prices, especially in our climate where warm floors on cold winter mornings feel like an absolute luxury.

There’s also what I call the “comfort premium” – that wonderful feeling of stepping onto a warm floor on a freezing January morning. It’s hard to put a price tag on this daily pleasure, but my clients consistently tell me it’s one of their favorite home features.

With proper installation and maintenance, your engineered hardwood over radiant heat should last 25+ years, comparable to traditional installations. This longevity further improves the system’s value proposition.

Don’t forget to check for potential savings through regional incentives! Many Massachusetts utility companies offer rebates or incentives for energy-efficient heating systems, including radiant floor heating. It’s always worth contacting your local utility provider to see what programs might currently be available.

For those interested in diving deeper into the energy efficiency comparison between radiant heat and conventional systems, I recommend reviewing the latest research on energy efficiency. The data consistently shows that radiant systems deliver superior comfort with less energy consumption – a rare win-win in home improvement projects.

Frequently Asked Questions about Heated Hardwood Floors on Concrete

What temperature should I set my radiant thermostat?

When it comes to heated hardwood floors on concrete, temperature control is absolutely crucial. The golden rule is simple: your floor surface temperature should never exceed 80°F (27°C). Going beyond this limit is asking for trouble—most manufacturers will actually void their warranties if you cross this threshold.

In our experience at Romero Hardwood Floors, we’ve found that a floor surface temperature between 75-78°F provides that perfect balance of cozy warmth without risking damage to your beautiful hardwood. Think of it as the “Goldilocks zone” for your floors—not too hot, not too cold, but just right.

When you first fire up your system, patience is key. Start at a modest 70°F and gradually increase by just 2-5°F per day until you reach your desired temperature. This gentle approach gives your hardwood time to adjust, much like slowly wading into a pool rather than diving in headfirst.

Concrete slabs are like thermal elephants—they never forget heat, and they move very slowly! The significant thermal mass means rapid temperature changes are both stressful to your flooring and wasteful of energy. Consistent settings work best, so avoid those dramatic temperature swings that might seem energy-efficient but actually cause more problems than they solve.

Always use floor sensors rather than just relying on ambient air temperature controls. The air in your room might feel perfectly comfortable while your floor is quietly overheating below. Those floor sensors are your early warning system against potential damage.

Can I retrofit radiant heat under existing hardwood on a slab?

“Can I add heated floors without tearing everything up?” This is one of the most common questions we hear at Romero Hardwood Floors. The honest answer is: it’s challenging, but possible in some situations.

The most reliable approach is removing and reinstalling your existing flooring. We carefully take up your hardwood (saving as much as possible), install the radiant system, then reinstall the flooring. This usually requires some board replacement, but preserves your floor’s overall character while adding modern comfort.

If you’re lucky enough to have access from below—perhaps through an unfinished basement ceiling—we can sometimes install ultra-thin electric systems beneath the subfloor without disturbing your existing hardwood. This approach is less disruptive but depends entirely on your home’s specific configuration.

Some newer “low-profile” electric systems add minimal height and can occasionally be installed by simply removing baseboards and creating subtle transitions at doorways. These systems are particularly valuable in renovation projects where every fraction of an inch matters.

Every home is unique, which is why we evaluate each retrofit situation individually. Factors like floor height constraints, access points, and your existing flooring type all influence which approach will work best. What’s impossible in one home might be straightforward in another, so it’s always worth asking for a professional assessment.

How long must new concrete cure before installing wood over radiant?

Patience truly is a virtue when it comes to new concrete slabs. They should cure for a minimum of 60-90 days before installing any type of wood flooring—and this waiting period is even more important when you have radiant heating systems embedded in the concrete.

I’ve seen too many beautiful floors fail because someone rushed this crucial step. As one of my mentors used to say, “Concrete isn’t done just because it’s hard enough to walk on.” Those slabs continue releasing moisture for months, and trapping that moisture under your new hardwood is a recipe for disaster.

During this curing process, protect your slab from additional moisture (no wet mopping!), and run your radiant system through a controlled “commissioning” process. This involves gradually increasing the system temperature over several days, holding it for a period, then allowing it to cool—effectively “exercising” the concrete before it needs to perform.

At Romero Hardwood Floors, we don’t rely on guesswork. We use ASTM F-2170 relative humidity testing to scientifically verify that concrete moisture levels have stabilized before proceeding. We simply won’t install flooring until the slab’s internal relative humidity drops below manufacturer-specified limits (typically 75-80% for engineered wood with vapor barriers).

This waiting period might seem frustrating when you’re eager to enjoy your new floors, but it’s a small investment of time that protects your much larger investment in beautiful heated hardwood floors on concrete. The patience pays off with floors that perform beautifully for decades instead of developing problems within the first year.

Conclusion

Installing heated hardwood floors on concrete creates a perfect marriage of beauty and comfort when done correctly. Throughout this guide, we’ve explored the intricate relationship between radiant heating systems, concrete slabs, and hardwood flooring. The journey from cold concrete to warm, inviting hardwood is one that transforms not just your floors, but your entire living experience.

The success of your heated floor project hinges on three fundamental elements: selecting appropriate materials, following proven installation methods, and maintaining proper environmental conditions. Each of these factors plays a crucial role in ensuring your floors remain beautiful and functional for decades to come.

At Romero Hardwood Floors Inc., we’ve refined our approach to these specialized installations through years of experience serving homeowners across Massachusetts. From the coastal communities of Beverly to the busy neighborhoods of Woburn, we’ve helped countless families find the luxury of warm floors beneath their feet. Our team understands the science behind the systems and the artistry needed to create floors that delight both the eye and the touch.

The change that heated hardwood floors on concrete brings to a home is something our clients frequently describe as life-changing. As Maria from Revere recently shared with us, “I never realized how much of a difference heated floors would make. It’s changed how we live in our home – we actually look forward to winter mornings now!” This sentiment captures exactly why we’re so passionate about these installations – they truly improve daily living in a tangible way.

When winter winds howl outside your Massachusetts home, there’s nothing quite like stepping onto warm wood floors first thing in the morning. That simple pleasure represents the perfect balance of luxury and practicality that makes radiant heated hardwood such a worthwhile investment. Beyond the immediate comfort, these systems add significant value to your property while potentially reducing your overall heating costs.

Whether you’re building new construction or renovating an existing space, heated hardwood floors on concrete deserve serious consideration. With thoughtful planning, quality materials, and expert installation, you’ll create a foundation of comfort that improves your home for years to come.

Ready to transform your concrete floors into warm, inviting hardwood surfaces? Our team at Romero Hardwood Floors Inc. is here to guide you through every step of the process. We proudly serve communities throughout eastern Massachusetts, bringing our expertise and craftsmanship to homes just like yours.

For more information about our professional installation services, visit: More info about professional installation services

Warm feet, happy home – that’s the Romero Hardwood Floors promise, and we look forward to helping you experience the difference that heated hardwood floors on concrete can make in your daily life.