hardwood flooring over radiant heated concrete: 1 Solution

Why Hardwood Flooring Over Radiant Heated Concrete Is More Complex Than You Think

Hardwood flooring over radiant heated concrete offers an ideal combination of luxury and comfort, but a successful installation requires careful planning to avoid costly failures.

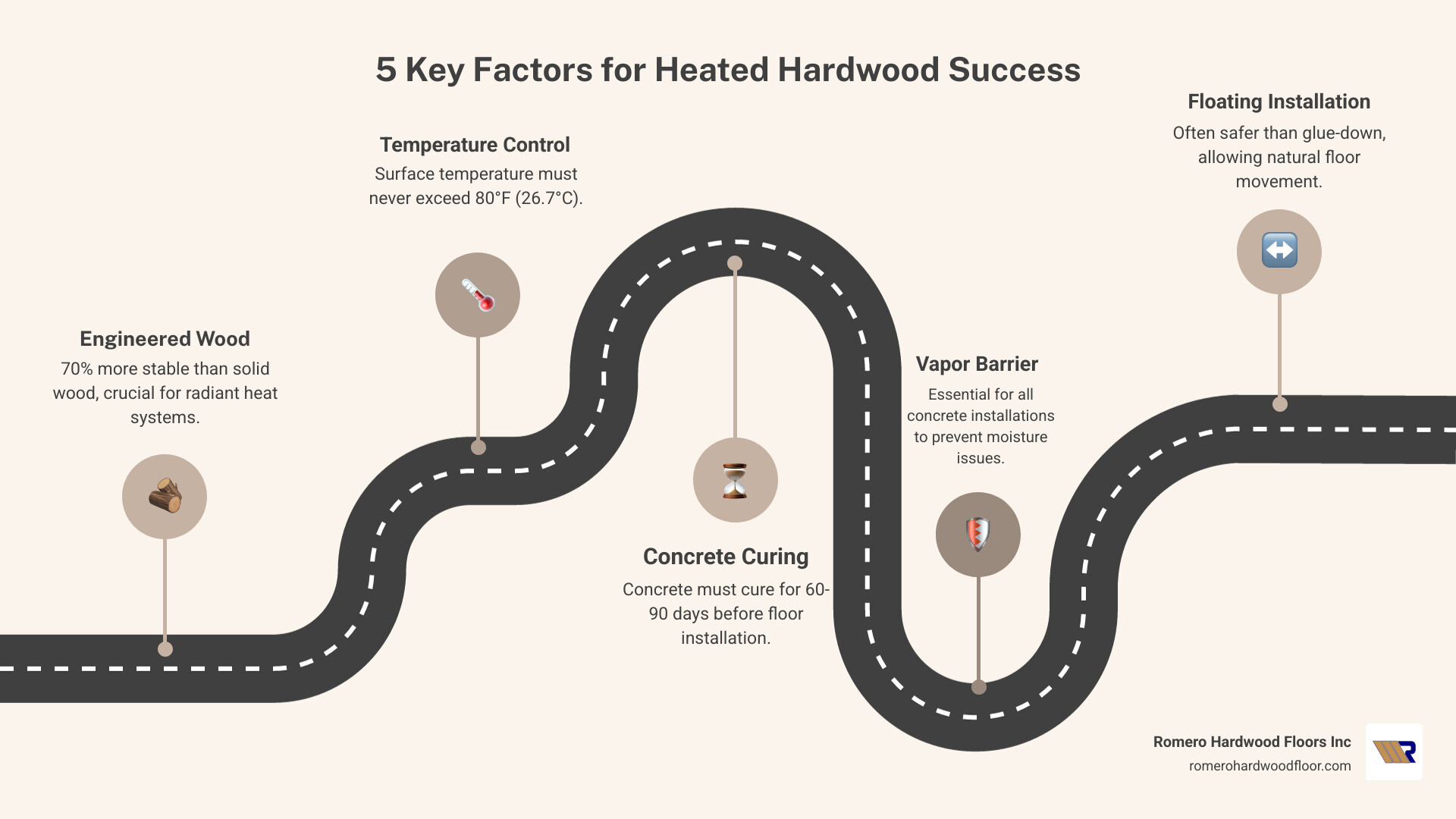

Key Compatibility Factors:

- Engineered hardwood is significantly more stable than solid wood.

- Surface temperature must not exceed 80°F (26.7°C).

- Concrete must cure for a minimum of 60-90 days.

- Vapor barriers are non-negotiable for all concrete subfloors.

- Floating installation is generally safer than glue-down methods.

- Wood species stability is critical; avoid maple, hickory, and Brazilian cherry.

The stakes are high. Improper installations can lead to severe cupping and cracking within a single heating season.

The main challenges include:

- Wood movement from temperature and humidity changes

- Concrete moisture vapor transmission

- Uneven heat distribution causing hot spots

- Installation complexity requiring specialized techniques

I’m Francisco Romero, owner of Romero Hardwood Floors Inc. With over 15 years of experience installing these systems in eastern Massachusetts, I’ve learned that proper material selection and installation techniques are the keys to creating beautiful, durable heated floors.

Essential hardwood flooring over radiant heated concrete terms:

- Hardwood Floor Installation Concrete

- engineered hardwood over concrete

- solid hardwood on concrete slab

Understanding the Core Challenges: Wood, Concrete, and Heat

Installing hardwood flooring over radiant heated concrete requires balancing three elements: wood, which is sensitive to moisture; concrete, which retains water; and heat, which causes movement. Harmonizing them requires expertise.

The biggest challenge is that wood naturally expands and contracts with changes in temperature and humidity. The heat from a radiant system, combined with moisture from the concrete below, creates a recipe for potential problems like cupping (edges curl up), crowning (centers rise), or gapping between planks.

Fortunately, these challenges are manageable with the right materials and proven installation techniques. For situations where moisture has already caused damage, our Hardwood Floor Water Damage Repair services can help restore your floors.

Why Wood Moves: The Science of Hygroscopic Materials

Wood is hygroscopic, meaning it acts like a sponge, absorbing and releasing moisture from the air. When humidity rises, wood expands; when it drops (as in most heated homes during winter), it shrinks. Radiant heat from below amplifies this effect by constantly drying the wood.

These moisture changes can cause cupping, crowning, or gapping. To prevent these issues, maintain indoor relative humidity between 35-55% year-round. This keeps the wood stable and is healthier for your home. While seasonal changes are inevitable, avoiding dramatic humidity swings is crucial for long-term floor stability.

The Concrete Factor: Curing and Moisture Vapor

Concrete is great for radiant heat as it stores and releases warmth. However, new concrete contains significant water that must evaporate before flooring installation.

New concrete must cure for a 60-90 day minimum before installation. This is a strict requirement. During this period, much of the water evaporates, but the slab can still emit moisture vapor for months.

Moisture testing is therefore critical. The ASTM F-2170 standard is the most accurate method. A simple DIY test involves taping a 3×3 ft plastic sheet to the slab for 48 hours; condensation underneath indicates the slab is too wet for installation.

A high-quality vapor barrier meeting ASTM E 1745 standards is essential to shield the wood from moisture vapor. Additionally, the slab must be flat. Your subfloor should be level within 3/16 inch over a 10-foot radius to prevent hollow spots and squeaking.

For complete guidance on concrete preparation, see our guide on Installing Hardwood Floors on Concrete Slab.

Choosing the Right Hardwood and System

For hardwood flooring over radiant heated concrete, your choice of materials is the most critical factor for success. The right combination of wood, heating system, and installation method prevents costly failures.

The flooring’s thermal properties, or R-value, are key. It acts as insulation over the heat source. For efficient heating, the total flooring R-value should not exceed 1.5. Thicker or wider planks can negatively affect performance. Wood species stability also varies dramatically.

Engineered vs. Solid Hardwood: The Clear Winner

When it comes to hardwood flooring over radiant heated concrete, engineered hardwood is the superior choice. Its performance and stability are dramatically better than solid wood in a heated environment.

Here’s a quick comparison:

| Feature | Engineered Hardwood | Solid Hardwood |

|---|---|---|

| Dimensional Stability | High (up to 70% more stable than solid) due to cross-layered plywood or HDF core. | Low to Moderate (species-dependent); prone to cupping, crowning, gapping with temperature/moisture changes. |

| Radiant Heat Suitability | Excellent. Layers counteract wood’s natural movement, making it ideal for heated environments. | Problematic. Most manufacturers do not warranty 3/4″ solid hardwood over radiant heat due to its volatility. |

| Installation Options | Floating, glue-down, or nail-assist (if subfloor allows). Floating is often preferred for radiant heat. | Typically nail-down; limited options over concrete (often requires a plywood subfloor). |

| Heat Transfer | Generally good, especially with thinner engineered planks. | Can impede heat transfer if too thick; prone to issues if temperature limits are exceeded. |

| Warranty | Most engineered floating floors come with warranties for radiant heat applications, if installed correctly. | No warranty provisions from manufacturers for 3/4″ solid hardwood over radiant heat systems. |

| Cost (average) | $4-$12+ per square foot (material only, based on internet data). | $3-$15+ per square foot (material only, based on internet data). |

Engineered hardwood‘s cross-layered core provides superior resistance to expansion and contraction. Most manufacturers will not warranty solid hardwood over radiant heat, which speaks volumes about the risk involved. With engineered floors, you get peace of mind and better performance. Learn more in our guide to More info about Engineered Hardwood Flooring.

Best Wood Species and Plank Dimensions for Radiant Heat

Not all wood species handle heat equally. Some are very stable, while others react dramatically to temperature shifts.

Stable species we recommend include White Oak, Red Oak, Teak, American Walnut, and American Cherry. Quartersawn oak is particularly stable. Bamboo, especially strand-woven types, is also an excellent choice as it conducts heat well and remains stable.

Less stable species to avoid include Maple, Hickory, and Brazilian Cherry (Jatoba), as they are prone to significant movement with temperature changes.

Regarding the cut, quartersawn and rift-sawn lumber is more stable than plain-sawn, making it a worthwhile investment for radiant applications.

Plank dimensions are also crucial. For radiant heat, narrower is better. We recommend planks 3 inches wide or less for maximum stability. Thinner engineered planks also allow for more efficient heat transfer.

While More info about Wide Plank Hardwood Floors are popular, they are not the best choice for radiant heated concrete due to their tendency to show more movement.

Hydronic vs. Electric Radiant Systems

The choice between hydronic and electric systems significantly impacts your flooring installation.

Hydronic systems use heated water pumped through tubes in the concrete. They are highly energy-efficient for large areas and provide slow, even heat. However, they are slower to respond to temperature changes and are best installed during new construction.

Electric systems use resistance cables or mats, which heat up quickly and are easier to install during remodels. However, electric radiant heat pads should never be installed directly under hardwood flooring due to the risk of overheating and creating hot spots. If using an electric system, it must be properly designed not to exceed 15 watts per square foot.

Regardless of the system, professional design is critical. The system must be designed to keep the floor surface temperature below 80°F (26.7°C) and avoid hot spots.

For more details, see our guide on More info about Heated Hardwood Floors on Concrete.

Best Practices for Hardwood Flooring Over Radiant Heated Concrete

Properly installing hardwood flooring over radiant heated concrete requires precision and patience at every step. Success lies in the details, as shortcuts can lead to costly failures.

Success starts with clear communication between the heating contractor, concrete crew, and flooring installers. Everyone must understand the project’s timeline, temperature limits, and moisture requirements to prevent expensive mistakes. For a comprehensive overview, see our More info about Hardwood Floor Installation Concrete guide.

Step 1: Subfloor and System Preparation

This first step is foundational. The concrete slab must be perfectly prepared, as any issues here will cause long-term problems.

- Concrete Slab Testing: The slab must cure for at least 60-90 days. We test for moisture using the ASTM F-2170 standard. A simple plastic sheet test can also indicate if the slab is too wet.

- Leveling the Slab: The slab must be flat within 3/16″ over a 10-foot radius to prevent hollow spots, squeaks, and stress points. We use self-leveling compounds as needed.

- Vapor Retarder: A minimum 6-mil polyethylene vapor barrier (meeting ASTM E 1745 standards) is non-negotiable. It shields the wood from moisture damage.

- Running the Heat System: Before installation, run the heating system at 65-70°F for at least 72 hours (a week is preferable) to drive out residual moisture and stabilize the environment.

- Checking for Hot Spots: We check for areas where tubing is too close to the surface, which can damage the wood. It’s crucial to fix these issues before installation.

For floating floors, choosing the right underlayment is part of this step. Learn more about More info about Hardwood Floor Underlayment Options.

Step 2: Acclimation is Non-Negotiable

Acclimation is a critical step that ensures your hardwood flooring over radiant heated concrete remains stable. It allows the wood to adjust to the home’s environment before permanent installation.

Bring the wood into the climate-controlled space only after the subfloor is prepped and the heat is running. Stick-stack the flooring with spacers to allow air to circulate around every plank.

The radiant heat system must run at a consistent 65-70°F during the entire acclimation period. We recommend a minimum two-week acclimation period for engineered hardwood over radiant heat; rushing this step often leads to problems.

Throughout this time, we monitor the wood’s moisture content. The wood is ready for installation when its moisture content stabilizes between 6-9% and matches the home’s ambient conditions. For more on this step, see More info about Engineered Wood Floor Acclimation.

Step 3: Installation Methods for Hardwood Flooring Over Radiant Heated Concrete

The chosen installation method determines the long-term performance of your hardwood flooring over radiant heated concrete.

Floating floor installation is our preferred method for most radiant heat projects. The planks connect to each other but “float” over the subfloor, allowing the entire floor to expand and contract as a single unit. This minimizes gapping and stress on the planks and eliminates the risk of puncturing radiant heat tubes.

Glue-down installation is another option that provides excellent heat transfer and a solid feel. However, it requires a perfectly flat, clean slab and a specialized, flexible adhesive designed for radiant heat. We advise against gluing flooring directly over exposed radiant tubing; a plywood underlayment should be installed first to protect the tubes.

Regardless of the method, proper expansion gaps around the room’s perimeter are crucial to allow for natural wood movement. We also take extreme care to avoid damaging the tubing during installation.

For step-by-step guidance, check out More info about How to Install Floating Engineered Hardwood Flooring on Concrete.

Operating and Maintaining Your Heated Floors

Once your hardwood flooring over radiant heated concrete is installed, proper operation and maintenance are key to its longevity. Consistent care will ensure it performs beautifully for decades.

Maintaining stable conditions and following proper care practices will protect your investment. For comprehensive guidance, explore our More info about Hardwood Floor Care Guide.

Critical Temperature and Humidity Control

Temperature and humidity control are non-negotiable for heated wood floors.

- Maximum Surface Temperature: Never exceed 80°F (26.7°C) at the floor surface. While some manufacturers may permit 85°F, staying at or below 80°F is the safest practice. Overheating can cause irreparable gaps and cupping.

- Gradual Temperature Changes: When adjusting your system seasonally, change the temperature by only 2-5 degrees per day. Sudden changes can shock the wood and cause damage.

- Humidity Control: Maintain your home’s relative humidity between 35% and 55% year-round. Use a whole-house humidifier in winter and a dehumidifier in summer to prevent gapping or swelling.

Professional installations should include in-floor temperature sensors for precise monitoring to prevent overheating.

Long-Term Maintenance and Protection

Daily habits play a significant role in your floor’s longevity.

- Avoid Area Rugs: Rugs can trap heat, creating hot spots that damage the wood underneath. If you use rugs, choose breathable materials and move them periodically.

- Furniture Protection: Use felt or rubber pads under all furniture legs to prevent scratches. Be aware that heavy furniture can also trap heat.

- Proper Cleaning: Use only cleaning products specifically designed for hardwood floors. Never use steam cleaners or excessive water, as the combination of heat and moisture is especially damaging. See our guide on More info about Hardwood Floor Cleaning Products.

- Regular Inspections: Periodically check your floors for any new gaps, cupping, or other changes. Early detection allows for quick adjustments to prevent larger issues.

With consistent care, your heated hardwood floors will provide warmth and beauty for many years.

Frequently Asked Questions about Hardwood Over Radiant Heat

Here are answers to the most common questions about installing hardwood flooring over radiant heated concrete.

Can I install solid 3/4″ hardwood over radiant heat?

While technically possible, installing traditional 3/4″ solid hardwood over radiant heat is not recommended. Most manufacturers do not warranty this application due to the high risk of cupping, gapping, and splitting.

Solid wood is too unstable when exposed to constant temperature cycling. If you insist on solid wood, narrow, quartersawn planks of a stable species like White Oak offer the best chance of success, but it remains a significant risk.

Engineered hardwood is the recommended choice, as it is designed for the temperature and moisture fluctuations of a radiant heat system.

What happens if the floor temperature gets too high?

Exceeding the recommended surface temperature of 80-85°F (26.7-29.44°C) can cause permanent, costly damage. The effects include:

- Gapping: The wood shrinks from excessive drying, creating large spaces between planks.

- Cupping and Cracking: Boards can curl at the edges or crack through the plank.

- Finish Damage: The floor’s finish can become brittle and peel.

- Delamination: On engineered floors, the top wood layer can separate from the core.

Proper system design with in-floor temperature sensors is essential to prevent these disasters.

Is a floating or glue-down installation better for radiant heat?

Both methods can be successful for hardwood flooring over radiant heated concrete, but they have different advantages.

- Floating Installation: This is often the preferred method because it allows the entire floor to expand and contract as one unit, minimizing gaps between boards. It also eliminates the risk of puncturing radiant tubes. Modern underlayments and quality planks reduce any “hollow” sound.

- Glue-Down Installation: This method provides excellent heat transfer and a more solid feel underfoot. However, it requires a perfectly flat subfloor and a specialized, flexible adhesive designed to withstand heat. It is less forgiving of wood movement.

For most projects, a floating installation offers a more reliable and forgiving solution that better accommodates the movement associated with heated floors.

Conclusion

Installing beautiful hardwood flooring over radiant heated concrete is an achievable goal for homeowners throughout Revere, Chelsea, Beverly, Danvers, and all of eastern Massachusetts. With careful planning, it provides an unparalleled combination of luxury and comfort.

While there are challenges with wood movement, concrete moisture, and heat, understanding and respecting these materials ensures they work together beautifully.

The keys to success are:

- Smart Material Choices: Engineered hardwood is far more stable than solid wood. Stable species like White Oak and narrower planks are best.

- A Precise Process: A fully cured concrete slab, a patient acclimation period, and a professional installation are all non-negotiable.

- Ongoing Care: Maintaining a surface temperature at or below 80°F and indoor humidity between 35-55% will protect your investment for decades.

At Romero Hardwood Floors Inc., we have specialized in hardwood flooring over radiant heated concrete since 2006. Our success comes from combining technical expertise with a commitment to quality craftsmanship. We show up on time, offer competitive pricing, and stand behind our work.

The comfort, beauty, and value of heated hardwood floors are all achievable with the right approach and experienced professionals.

Ready to transform your space? For expert guidance on your project, explore our Hardwood Flooring Installation services and let’s discuss how we can bring your vision to life.

Like us on Facebook!