Engineered Wood Floor Adhesive: Top 3 Best Choices 2025

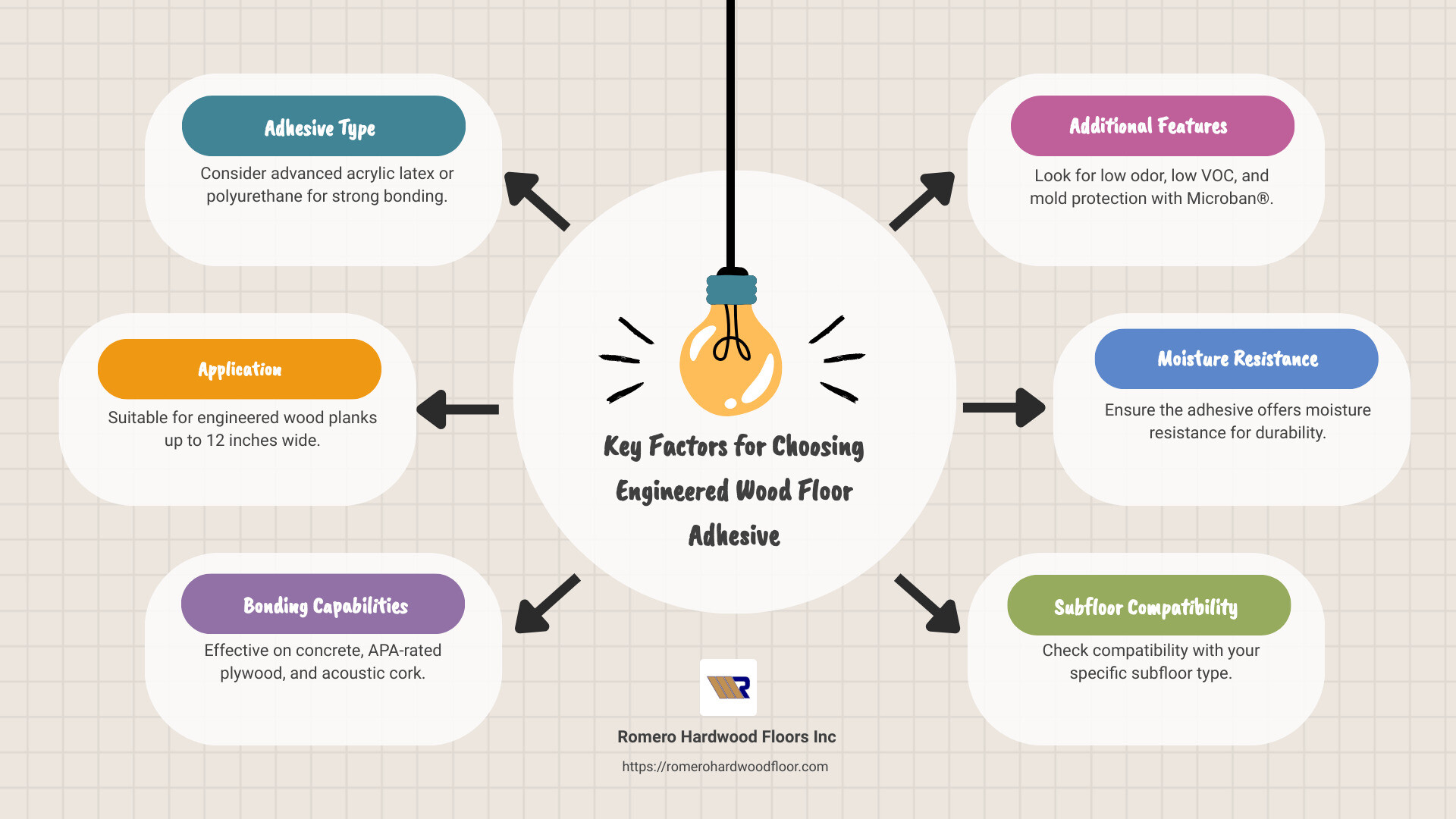

When it comes to choosing the right engineered wood floor adhesive, the options can be overwhelming. To make the best choice for your flooring project, consider these key factors:

- Adhesive Type: Advanced acrylic latex or polyurethane.

- Application: Ideal for engineered wood planks, particularly up to 12 inches wide.

- Bonding Capabilities: Effective on concrete (on and above grade), APA-rated plywood, and acoustic cork underlayment.

- Additional Features: Low odor, low VOC, and mold protection with Microban®.

With the right adhesive, your engineered wood floors will not only look stunning but also stand up to the challenges of daily wear and tear.

Choosing the perfect adhesive for engineered wood floors is crucial for ensuring a smooth installation and long-lasting results. Whether you’re renovating a commercial space or enhancing your home, the adhesive you select plays a pivotal role in the overall success of the project. As you steer the plethora of options, from solvent-free acrylics like the 1487 ENGINEERED+ to robust polyurethane choices, focus on elements like bond strength, open and curing times, and the specific characteristics of your subfloor.

As Francisco Romero, with over 15 years of experience at Romero Hardwood Floors Inc., I know the ins and outs of adhesive selection. Trusting professionals for installations can make the difference between simply laying a floor and achieving true bonding success.

Relevant articles related to engineered wood floor adhesive:

– engineered hardwood floor refinishing

– engineered wood floor cleaning

Understanding Engineered Wood Floor Adhesives

When installing engineered wood flooring, choosing the right engineered wood floor adhesive is essential. The two primary types of adhesives used in these installations are polyurethane and acrylic latex. Let’s explore what makes each of these unique and how they contribute to a successful flooring project.

Polyurethane Adhesives

Polyurethane adhesives are known for their strong bonding capabilities. They are ideal for engineered wood flooring because they provide a durable and flexible bond. This flexibility is crucial as it allows the floor to expand and contract with changes in temperature and humidity without losing adhesion.

- Advantages:

- Excellent moisture resistance, making them suitable for areas with high humidity.

- Strong bond strength, suitable for high-traffic areas.

- Versatile, as they can be used on various subfloors.

- Considerations:

- They can emit strong odors during application, so proper ventilation is necessary.

- Longer curing times compared to other adhesives, which might extend the installation process.

Acrylic Latex Adhesives

Acrylic latex adhesives, like the 1487 ENGINEERED+, are solvent-free and provide a strong, reliable bond. They are particularly favored for their low odor and low VOC emissions, making them an environmentally friendly choice.

- Advantages:

- Quick drying time, with up to 20 minutes open time and 30 minutes working time.

- Lower odor and VOC emissions, ideal for residential and commercial settings.

- Improved mold and mildew protection, thanks to Microban® technology.

- Considerations:

- Best suited for installations on concrete, APA-rated plywood, and acoustic cork underlayment.

- Coverage may vary based on trowel type and installation conditions.

Choosing the Right Adhesive

Selecting between polyurethane and acrylic latex depends on several factors, including environmental conditions, subfloor type, and personal preferences regarding installation speed and environmental impact. Both types of adhesives have their strengths, and understanding these can help you make an informed decision.

In summary, the right adhesive ensures your engineered wood flooring remains beautiful and functional for years to come. Whether you opt for the flexibility of polyurethane or the eco-friendliness of acrylic latex, consider your specific needs and consult with professionals like those at Romero Hardwood Floors Inc. to achieve the best outcome for your flooring project.

Top Adhesives for Engineered Hardwood

When it comes to installing engineered hardwood, choosing the right adhesive is critical. Two top contenders in this space are Bostik’s BEST and 1487 Engineered+. Each offers unique benefits, especially in moisture control, which is crucial for maintaining the durability and appearance of your flooring over time.

Bostik’s BEST

Bostik’s BEST is a high-performance urethane adhesive known for its exceptional bond strength and moisture control capabilities. It’s designed to provide a tough, flexible bond to a variety of surfaces, making it a versatile choice for different flooring types and subfloors.

- Key Features:

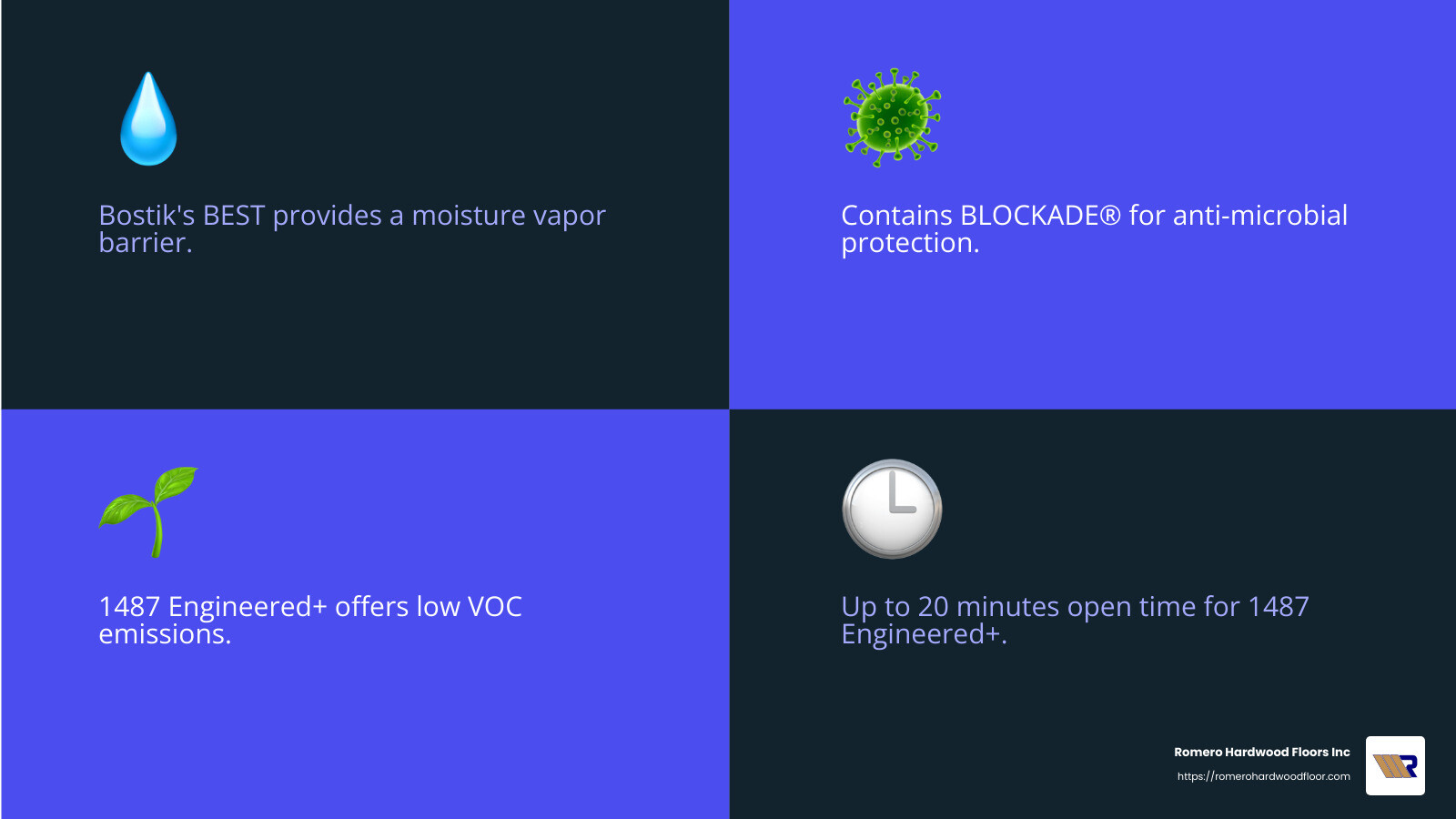

- Moisture Control: Bostik’s BEST acts as a moisture control membrane, reducing moisture vapor transmission through concrete. This feature eliminates the need for costly and time-consuming moisture testing when installing engineered hardwood on properly prepared slabs.

- Anti-Microbial Protection: The adhesive includes Bostik’s BLOCKADE® technology, which inhibits the growth of bacteria, mold, and mildew on the surface of the dried adhesive.

- Elasticity: The urethane glue’s elastomeric properties allow it to move with the wood, accommodating expansion and contraction due to humidity and temperature changes.

Bostik’s BEST is particularly suitable for environments where moisture is a concern, providing peace of mind and superior performance in both residential and commercial settings.

1487 Engineered+

The 1487 Engineered+ is an advanced acrylic latex adhesive that offers a strong, reliable bond for engineered wood flooring installations. This adhesive is solvent-free, making it an environmentally friendly option with low odor and VOC emissions.

- Key Features:

- Quick Drying: With up to 20 minutes open time and 30 minutes working time, this adhesive allows for efficient installation, while its 24-hour curing time ensures stability.

- Mold and Mildew Protection: Powered by Microban® technology, the 1487 Engineered+ provides improved protection against mold and mildew, ensuring a healthier indoor environment.

- Versatile Application: Suitable for use on concrete, APA-rated plywood, and acoustic cork underlayment, this adhesive is ideal for various installation scenarios.

The 1487 Engineered+ is perfect for projects where quick installation and environmental considerations are a priority, offering a balance of performance and eco-friendliness.

Moisture Control

Both Bostik’s BEST and 1487 Engineered+ excel in moisture control, a vital aspect of maintaining the integrity of engineered hardwood flooring. Moisture can lead to warping, buckling, and other forms of damage, so selecting an adhesive with effective moisture management is crucial.

- Bostik’s BEST: Its urethane formula provides a moisture vapor barrier, making it an excellent choice for installations over concrete.

- 1487 Engineered+: While not specifically a moisture barrier, its acrylic latex composition offers some resistance and is complemented by the adhesive’s quick drying time, reducing the window for moisture-related issues.

In conclusion, the choice between Bostik’s BEST and 1487 Engineered+ will depend on your specific needs, such as the type of subfloor, environmental conditions, and installation priorities. Both adhesives offer robust solutions for engineered hardwood installations, ensuring your floors remain beautiful and resilient.

How to Choose the Right Adhesive

Selecting the right engineered wood floor adhesive is crucial for a successful installation. Here’s what you need to consider:

Subfloor Compatibility

The type of subfloor you have will largely determine which adhesive to use. For example, 1487 Engineered+ is versatile and works well with concrete, APA-rated plywood, and acoustic cork underlayment. This makes it a great choice for a variety of residential and commercial settings.

Bostik’s BEST can be used on even more surfaces, including OSB, well-bonded vinyl, and ceramic tile. This makes it ideal for more complex projects with diverse subfloor materials.

Moisture Resistance

Moisture is a common enemy of wood flooring. It’s vital to choose an adhesive that offers moisture control to prevent damage like warping or buckling. Bostik’s BEST is exceptional in this area, acting as a moisture control membrane that reduces vapor transmission through concrete. This feature is especially beneficial for installations over concrete slabs, eliminating the need for additional moisture testing.

For projects where moisture is less of a concern, the 1487 Engineered+ provides adequate resistance and quick drying time, which helps minimize moisture exposure during installation.

Installation Conditions

Consider the working time and curing time of the adhesive to match your installation schedule. 1487 Engineered+ offers up to 20 minutes open time and a 30-minute working time, allowing for a more flexible installation process. Its 24-hour curing time ensures a strong bond is formed quickly.

On the other hand, Bostik’s BEST offers immediate green grab after troweling, making it easier to secure the flooring in place. This is beneficial for larger projects where speed and efficiency are critical.

In summary, when choosing an adhesive, consider the compatibility with your subfloor, the level of moisture resistance needed, and the specific installation conditions. These factors will guide you to the best choice for your engineered wood flooring project.

Installation Tips for Engineered Wood Flooring

Installing engineered wood flooring can be a smooth process if you follow a few key tips. Let’s explore some practical advice on trowel types, curing time, and ventilation to ensure a successful installation.

Trowel Types

Choosing the right trowel is essential for applying engineered wood floor adhesive evenly. The size and shape of the trowel teeth will determine the adhesive coverage and grip.

- Square-notch trowels are commonly used for engineered wood flooring. The size of the notches affects how much adhesive is applied. For wider planks, use a larger notch (e.g., 1/4 inch) to ensure better coverage and bonding.

- V-notch trowels are less common but can be used for smaller planks or when a thinner adhesive layer is needed.

Always refer to the adhesive manufacturer’s guidelines to select the appropriate trowel type for your specific flooring and adhesive.

Curing Time

Curing time is critical for the adhesive to form a strong bond. 1487 Engineered+ adhesive offers a 24-hour curing time, which is ideal for residential and commercial installations. Here’s how to make the most of it:

- Plan your work: Ensure that each section of the floor is completed within the adhesive’s working time. For 1487 Engineered+, you have a 30-minute window after application.

- Avoid foot traffic: Keep the area clear for at least 24 hours to allow the adhesive to cure properly. This prevents shifting and ensures a stable floor.

Ventilation

Proper ventilation is often overlooked but is essential for a successful installation. Good airflow helps with curing and minimizes odors.

- Open windows and doors: Allow fresh air to circulate in the room. This helps the adhesive dry evenly and reduces any lingering smell.

- Use fans: Place fans strategically to improve airflow. However, avoid direct air on the adhesive as it might cause uneven drying.

By focusing on these installation tips, you can ensure that your engineered wood flooring is laid down perfectly, providing a beautiful and durable finish.

Frequently Asked Questions about Engineered Wood Floor Adhesive

What is the best adhesive for engineered floors?

When it comes to choosing the best adhesive for engineered wood floors, polyurethane adhesives are a top choice. They offer excellent moisture resistance, making them ideal for areas where humidity might be a concern. This type of adhesive is known for its strong bond and flexibility, which helps the flooring adapt to changes in temperature and humidity without cracking.

In particular, products like 1487 Engineered+ are popular because they provide a reliable bond and are designed specifically for engineered wood flooring. These adhesives are easy to work with and ensure that your flooring stays in place for years to come.

Should engineered wood flooring be glued?

Deciding whether to glue engineered wood flooring depends on your specific needs and the environment where the flooring will be installed. There are two main installation methods: floating and glue down.

- Floating installation: This method involves connecting the planks without attaching them to the subfloor. It’s great for environments with fluctuating humidity levels because it allows the floor to expand and contract freely.

- Glue down installation: Here, each plank is glued directly to the subfloor. This method is preferred for areas where stability is crucial, such as high-traffic zones. It provides a firmer feel underfoot and reduces noise, making it a popular choice for multi-story buildings.

Why is my engineered wood floor sticky?

If your engineered wood floor feels sticky, it might be due to a few reasons:

- Contamination: Sometimes, residues from previous cleaning products or spills can leave a sticky film on the surface. It’s essential to use cleaning products specifically designed for engineered wood to prevent this issue.

- Improper adhesive curing: If the adhesive wasn’t given enough time to cure or if the room wasn’t adequately ventilated, it might not set correctly, leading to a sticky feel.

- Maintenance products: Overusing or misusing maintenance products, such as polishes or waxes, can also cause stickiness. Always follow the manufacturer’s instructions and use products recommended for your specific flooring type.

Understanding these common questions can help you make informed decisions about your engineered wood floor adhesive and ensure a long-lasting, beautiful floor.

Conclusion

At Romero Hardwood Floors Inc, we pride ourselves on providing expert solutions for your flooring needs. Our team specializes in the installation of engineered hardwood floors, ensuring your home or business benefits from the best in craftsmanship and material selection.

Choosing the right engineered wood floor adhesive is crucial for a successful installation. Our expertise in adhesives, like the 1487 Engineered+ and polyurethane options, guarantees that your flooring will stand the test of time. We understand the nuances of subfloor compatibility, moisture resistance, and the importance of selecting the right adhesive for each unique project.

By opting for our services, you’re not just getting a floor; you’re enhancing your property’s value. Properly installed engineered wood flooring can significantly boost your home’s appeal and market value. Our commitment to quality and customer satisfaction ensures that your investment in flooring translates into long-term benefits.

For more information on how we can help you with your engineered hardwood flooring needs, visit our engineered hardwood flooring service page. Let us help you create a beautiful and lasting foundation for your space.