Floating Floor Underlayment: Flawless Finish 2025

Why Floating Floor Underlayment Matters for Your Installation

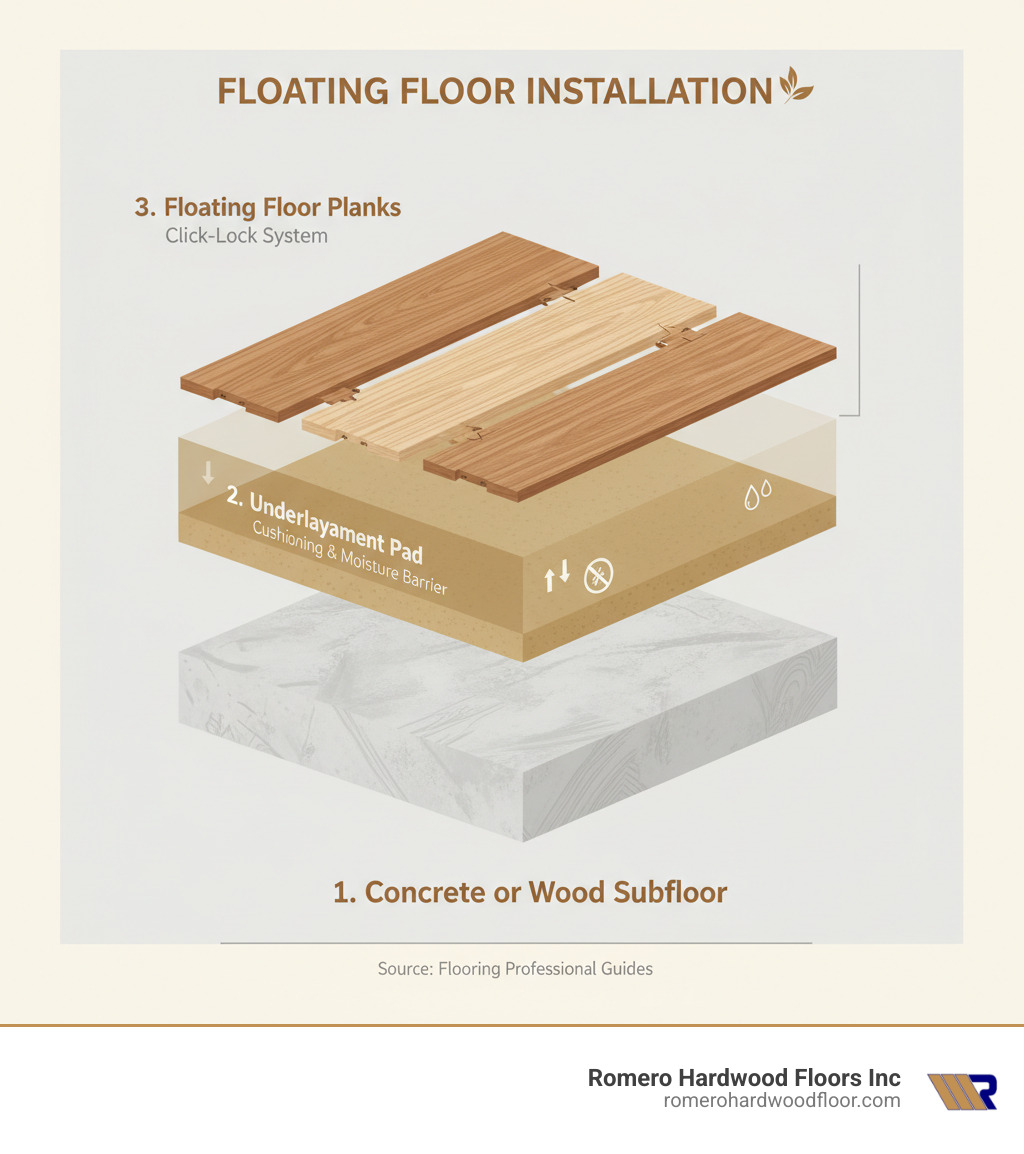

Floating floor underlayment is a thin, cushioning layer installed between the subfloor and your new floating floor. This essential component provides moisture protection, sound absorption, and smooths minor subfloor imperfections, ensuring your floor performs correctly and lasts for years.

Key types of underlayment materials:

- Foam – A budget-friendly choice ($0.50-$1.50 per sq ft) that provides basic cushioning and sound dampening.

- Cork – A natural, eco-friendly material offering excellent sound absorption and thermal insulation ($1.00-$4.00+ per sq ft).

- Felt – A dense, durable option with superior soundproofing, often including an integrated vapor barrier ($0.80-$3.50+ per sq ft).

(Note: Prices are estimates based on market averages and do not reflect specific pricing from Romero Hardwood Floors Inc.)

What underlayment does for your floating floor:

- Absorbs impact noise from footsteps.

- Protects against moisture, warping, and mold.

- Smooths out minor subfloor irregularities.

- Adds cushioning for underfoot comfort.

- Provides thermal insulation for warmer floors.

Many homeowners overlook what’s underneath their new floors. As one manufacturer puts it: “Laminate flooring without underlayment is like having a high-performance sports car with an economy car engine.” The underlayment gives your floating floor its performance.

Without proper underlayment, your floor will feel hollow, transmit noise, be vulnerable to moisture, and likely fail prematurely. The locking systems between planks can be damaged by even slight subfloor imperfections, leading to gaps and creaking.

I’m Francisco Romero, owner of Romero Hardwood Floors Inc. With over 15 years of experience, I’ve seen how the right floating floor underlayment makes the difference between a floor that performs beautifully and one that disappoints. Choosing the proper underlayment protects your investment and ensures lasting comfort.

The Essential Benefits of Underlayment for Floating Floors

After installing floors for over 15 years, I can tell you that floating floor underlayment isn’t optional—it’s the foundation that makes everything else work. This thin layer protects against moisture, smooths subfloor imperfections, absorbs sound, and adds comfort underfoot. Without it, you’re setting yourself up for problems.

As floating floors expand and contract with the seasons, underlayment acts as a buffer, protecting both the subfloor and the flooring from the stress of movement. It fills minor irregularities so planks have a stable surface, preventing damage to the delicate locking systems that hold the floor together.

A good underlayment also makes your home quieter by absorbing the sound of footsteps and dropped objects. Your family and neighbors will thank you. For more insights on how quality materials improve performance, check out our guide on Engineered Hardwood Benefits.

Improved Comfort and Insulation

Floating floor underlayment adds a subtle cushioning effect that makes your floor feel softer and more comfortable. This gentle give absorbs impact, reducing stress on your joints and making it easier to stand or walk for long periods, especially over hard concrete subfloors.

Beyond comfort, underlayment provides valuable thermal insulation. Materials like felt and cork are particularly effective at keeping floors warmer during cold months. By slowing heat transfer between your subfloor and living space, underlayment can improve your home’s energy efficiency and potentially lower heating costs. It’s a small detail that makes a big difference in daily comfort.

Superior Sound Absorption

One of the best features of a quality installation is how quiet the floor feels. Floating floors can transmit sound easily, but a quality floating floor underlayment solves this problem by absorbing impact noise—the sounds from footsteps, dropped objects, or moving furniture. This significantly reduces noise transfer to rooms below and prevents echoes within the space.

The flooring industry uses two ratings to measure sound absorption. STC (Sound Transmission Class) measures how well a material reduces airborne sound, while IIC (Impact Insulation Class) measures its ability to absorb impact noise. You can learn more about these ratings and how they are measured on Wikipedia. Premium underlayments can achieve impressive ratings, with some products offering an IIC of 25 and an STC of 66.

Dense felt and cork underlayments are especially effective at sound dampening. In multi-story buildings, condos, or apartments, these materials are often required by building codes or homeowner associations to ensure a peaceful living environment for all residents.

Protection and Longevity

Underlayment extends the life of your floor in several critical ways, making it a crucial part of protecting your investment. Moisture protection is paramount. Many underlayments include an integrated moisture barrier, which is essential over porous concrete subfloors that continuously emit moisture. Without a barrier, this moisture can cause warping, cupping, and buckling, leading to floor failure.

A moisture barrier also inhibits mold and mildew growth, protecting your indoor air quality. If you’re dealing with existing moisture issues, our guide on Hardwood Floor Water Damage Repair offers solutions.

Underlayment also smooths minor subfloor imperfections like small bumps or dips. Without this, these irregularities put constant stress on the planks’ locking systems, causing separation, creaking, and premature wear. By providing stable support for the locking mechanisms, a quality underlayment ensures your floor stays tight, quiet, and secure for years to come.

A Guide to Floating Floor Underlayment Materials

Choosing the right floating floor underlayment can feel overwhelming, but understanding the key differences between materials will help you make the best choice. Performance often tracks with price: basic foam offers fundamental benefits, while premium felt or cork provide superior sound absorption, insulation, and durability. At Romero Hardwood Floors Inc., we can help you select the right option based on your priorities, subfloor, and budget.

Here’s how the most common underlayment materials compare:

| Feature | Foam Underlayment | Cork Underlayment | Felt Underlayment |

|---|---|---|---|

| Cost (per sq ft) | $0.50 – $1.50 | $1.00 – $4.00+ | $0.80 – $3.50+ |

| Sound Absorption | Basic | Excellent (especially impact noise) | Superior (impact & some airborne) |

| Moisture Resistance | Often requires separate barrier; some have attached | Good (naturally resistant); may need separate vapor barrier on concrete | Good; often includes integrated vapor barrier |

| Durability | Fair | Good | Excellent |

| Comfort/Cushion | Basic | Excellent | Very good |

| Insulation | Basic | Good | Excellent |

| Eco-Friendliness | Varies (some recycled) | Excellent (natural, renewable) | Good (often made from recycled fibers) |

| Best Use Cases | Budget-conscious projects, laminate, engineered wood | Multi-story dwellings, sound-sensitive areas, eco-friendly projects | High-traffic areas, superior sound dampening, insulation needs |

Please note that these costs are average prices based on internet data and do not reflect specific pricing from Romero Hardwood Floors Inc.

Foam Underlayment

Foam underlayment is the most common and affordable type of floating floor underlayment. Made from polyethylene, it’s a great choice for budget-conscious projects, providing basic cushioning and some sound dampening. It’s lightweight and easy to install, making it popular for DIYers. Many foam products are available as “2-in-1” or “3-in-1” options with an attached vapor barrier, simplifying the installation process.

However, foam is less durable than premium materials and can compress over time in high-traffic areas, reducing its effectiveness. While the attached vapor barrier is convenient, a separate, more robust 6-mil plastic vapor barrier is often recommended for concrete subfloors or moisture-prone areas.

Cork Underlayment

For a premium, eco-conscious option, cork floating floor underlayment is an excellent choice. Harvested from the bark of cork oak trees, it’s a renewable and sustainable material. Learn more about sustainable options in our guide to Eco-Friendly Hardwood Flooring.

Cork is renowned for its sound absorption, especially for impact noise, making it ideal for condos and multi-story homes. It also provides good thermal insulation, helping regulate floor temperature and potentially lowering energy bills. Cork is naturally antimicrobial, resisting mold and mildew. While it is moisture-resistant, it is not a full vapor barrier, so a separate 6-mil plastic sheet is still needed over concrete. The main drawback is its higher cost, but many find the benefits in comfort, quietness, and sustainability justify the investment.

Felt Underlayment

Dense felt is a premium floating floor underlayment often made from recycled fibers. It is denser and more durable than foam, offering a significant upgrade in performance. For more details, see our Hardwood Floor Underlayment Options article.

Felt excels at sound dampening, reducing both impact and some airborne noise to create a floor that feels solid and quiet. Its thermal performance is also excellent, providing strong insulation that is especially useful over unheated spaces like garages. Felt’s dense composition resists crushing under heavy furniture, which is crucial for protecting your floor’s locking system. While it costs more than foam, the improved durability, sound absorption, and insulation make felt a worthwhile upgrade for those seeking top-tier performance.

Key Installation and Selection Considerations

Proper installation is just as important as choosing the right floating floor underlayment. A beautiful floor can fail within months if the subfloor isn’t prepared correctly. For a complete overview, our Hardwood Flooring Installation Guide is a valuable resource.

Before you begin, your subfloor must be flat, clean, and dry. The industry standard for flatness is within 1/8 inch over a 6-foot span or 3/16 inch over a 10-foot span. Use a leveling compound to fill dips and sand down any bumps. A thorough cleaning to remove all dust and debris is also essential. Finally, ensure the subfloor is completely dry, as moisture is the enemy of floating floors.

Always check the flooring manufacturer’s recommendations before buying underlayment. Using an incompatible product can void your warranty and lead to poor performance.

Choosing the Right Thickness for Your Floating Floor Underlayment

When it comes to underlayment thickness, thicker isn’t always better. For most laminate and engineered wood, the ideal thickness is between 2mm and 3mm. This range provides the right amount of cushioning and sound dampening without creating instability.

Using an underlayment that is too thick causes excessive flex, which puts stress on the floor’s locking joints. This can lead to gaps, creaking, and eventual joint failure. It can also create problems with door clearance, requiring you to trim doors. Furthermore, exceeding the manufacturer’s specified maximum thickness will void your flooring warranty. Always stick to the recommended thickness. If your flooring has a pre-attached pad, do not use an additional underlayment, as this will create the same instability.

When to Use a Vapor Barrier with Floating Floor Underlayment

Understanding when to use a vapor barrier is critical to prevent moisture damage like warping, mold, and floor failure. For more on this topic, see our guide on Floating Wood Floor Over Concrete.

A vapor barrier is non-negotiable in these situations:

- Concrete Subfloors: Concrete is porous and constantly releases moisture vapor. A barrier is essential to block this moisture.

- Below-Grade Installations: Basements and other spaces below ground level have higher moisture levels and always require a vapor barrier.

- Crawl Spaces: Moisture from the ground can travel up through the subfloor, making a vapor barrier necessary.

Before installing over concrete, a moisture test is recommended. If moisture emission is high, you may need additional protection, such as a concrete sealant or a separate layer of 6-mil polyethylene sheeting. While many underlayments have an integrated vapor barrier, in high-moisture areas, we often recommend using a separate 6-mil plastic sheet for added security. Even with cork underlayment, which is moisture-resistant, a separate plastic vapor barrier is required over concrete.

Specifics for Laminate vs. Engineered Wood

While both are floating floors, laminate and engineered wood have slightly different underlayment needs. For more on engineered wood, see our Engineered Hardwood Flooring Installation guide.

Laminate flooring has a high-density fiberboard core, making it more susceptible to telegraphing subfloor imperfections and creating a hollow sound without proper underlayment. A good floating floor underlayment is crucial for laminate to smooth the subfloor, absorb noise, and provide moisture protection, as its core will swell irreversibly if it gets wet.

Engineered wood is more forgiving due to its real wood veneer and stable core, but it still benefits greatly from the sound absorption and comfort of underlayment. Its locking systems also require a stable, supportive base to prevent wear and tear. Moisture protection remains just as important to prevent cupping or delamination.

The most important rule for both is to never double up on padding. If your flooring comes with a pre-attached pad, do not install a separate underlayment. This creates an unstable, bouncy surface that will damage the locking system and void your warranty.

Frequently Asked Questions about Underlayment

What happens if I don’t use underlayment with a floating floor?

Skipping floating floor underlayment is a costly mistake. Without it, your floor will sound hollow and loud, as there is no layer to absorb impact noise. It will be vulnerable to moisture from the subfloor, which can cause warping, buckling, and mold growth. Minor subfloor imperfections will put stress on the locking joints, leading to gaps, creaking, and premature failure of your floor. In short, you risk voiding your warranty and significantly shortening the life of your investment.

Can I install new underlayment if my flooring already has it attached?

No. You should never install a separate floating floor underlayment if your flooring already has a pad attached. This practice, known as “double-padding,” creates excessive flex under the floor. This instability puts immense stress on the locking mechanisms, causing them to separate, creak, or even break. Double-padding will void your flooring manufacturer’s warranty and lead to a failed installation.

How much does floating floor underlayment cost?

Please note that these are average costs based on internet data and do not reflect pricing from Romero Hardwood Floors Inc.

The cost of floating floor underlayment varies by material, but here are some general price ranges to help you budget:

- Basic Foam Underlayment: This is the most economical choice, typically running from $0.50 to $1.50 per square foot. It provides fundamental cushioning and sound dampening, often with an attached vapor barrier.

- Mid-Range Underlayments: This category includes denser foams, standard felt, and some cork blends, generally costing between $1.00 and $4.00 per square foot. These materials offer a significant step up in sound insulation, comfort, and durability.

- Premium Materials: High-quality cork, dense felt, and specialized rubber underlayments can range from $2.50 to over $7.50 per square foot. These options provide superior sound dampening, thermal insulation, and longevity, and are often required in condos with strict acoustic standards.

Typically, the price of underlayment reflects its performance. Investing in a quality material is a smart way to protect your new flooring and improve its comfort and durability for years to come.

Your Foundation for a Flawless Floor

As this guide has shown, choosing the right floating floor underlayment is one of the most important decisions for your new floor. This hidden layer works every day to protect your investment, muffle sound, block moisture, and ensure your floors feel comfortable and solid underfoot. The right underlayment transforms a good floor into a great one, ensuring it performs flawlessly for years.

At Romero Hardwood Floors Inc., we’ve been installing floors in the Revere, MA area since 2006, and we know that quality underlayment makes all the difference. Whether you’re installing laminate, engineered wood, or luxury vinyl, we’re here to guide you through every step, from selection to professional installation.

Our commitment to competitive pricing, punctuality, and guaranteed workmanship means you can trust us to treat your project with the care it deserves. We serve Revere and surrounding communities, including Beverly, Chelsea, and Peabody, providing expert hardwood floor installation services that improve your property’s value and comfort.

Ready to give your floating floor the foundation it deserves? Explore our hardwood floor underlayment options to find the perfect match for your project. Contact us today for expert guidance, and let’s build your new floors on a foundation that’s solid, silent, and built to last.