Floorboard Stain and Varnish: Ultimate 2025 Guide

Why Choosing the Right Floor Finish Matters

Floorboard stain and varnish are two distinct products that create beautiful, durable hardwood floors. Understanding their roles is key to making the best choice for your home and ensuring your floors look stunning for decades.

Quick Answer: Stain vs. Varnish

- Stain: Penetrates wood to add color and improve grain patterns.

- Varnish: Forms a protective topcoat to resist scratches, moisture, and wear.

- Best Practice: Use stain for color, then apply varnish for protection.

- Alternative: Combined products exist, but separate applications often yield superior results.

As one forum user noted, “Stain is just color… Varnish is a protective layer that can be renewed.” This highlights why understanding these products is crucial for your flooring investment. The choices between water-based and oil-based options, sheen levels, and application methods can seem complex, but this guide will help you make informed decisions that protect your floors and achieve your desired look.

I’m Francisco Romero, owner of Romero Hardwood Floors Inc. For over 15 years, I’ve helped homeowners in Revere, MA, and beyond select the perfect floorboard stain and varnish. My experience has shown that the right finish makes all the difference in both beauty and durability.

Common floorboard stain and varnish vocab:

Stain vs. Varnish: Understanding the Core Differences

Think of it this way: stain is the outfit that gives your wood floors style and personality, while varnish is the protective jacket that shields them from daily life. These two products work as a team, but they have completely different jobs. Stain focuses on color and enhancing natural beauty, while varnish provides the armor against scratches, spills, and wear.

Understanding this partnership is crucial for any flooring project. Let’s break down what each product does.

The Role of Wood Stain

Wood stain is a dye that soaks into your floorboards. Instead of sitting on top like paint, it penetrates the wood fibers to add rich color while allowing the grain patterns to show through. Stain is your floor’s personality improver, offering everything from deep espresso tones to light honey shades.

As the stain soaks in, it colors the wood itself, not just the surface. The wood’s natural pores and grain guide how the stain settles, creating the unique variations that make hardwood so special. While some stains offer minor sealing properties, their main job is aesthetics. For heavy-duty protection, you need varnish. See how we transform floors with color at our floor staining services page.

The Purpose of Varnish

If stain is the artist, varnish is the bodyguard. This clear, tough coating forms a protective film on your floor’s surface, guarding against furniture scratches, spills, and foot traffic. Most modern floor varnishes use polyurethane, a durable plastic coating that can handle serious abuse.

Varnish also controls your floor’s final look through sheen levels. Gloss offers a reflective, formal feel. Satin provides a popular soft shine that hides minor imperfections. Matte delivers an understated, natural look with almost no reflection. Without varnish, even the most beautiful stain job will quickly show wear and water damage.

Can I Just Use a Colored Varnish?

Products that combine stain and polyurethane in one application promise to save time, but separate applications usually give much better results, especially on floors.

When you apply stain first, you have complete control to work it in evenly and wipe off excess to prevent blotchiness. With a solid color foundation, you can then apply clear varnish with confidence.

Colored varnish makes even coverage difficult; any overlaps will create dark patches that are nearly impossible to fix. Furthermore, scratches become much more obvious. With a separate stain and varnish, a scratch typically only affects the clear topcoat, leaving the color in the wood below untouched. With a colored varnish, every scratch exposes the lighter wood underneath, highlighting the damage. While a combined product might work for a small project, the separate approach offers better control, more even results, and easier repairs for your floors.

Choosing Your Finish: A Breakdown of Stain and Varnish Types

Selecting the right floorboard stain and varnish depends on your project goals. High-traffic areas like family rooms need tougher finishes, while low-traffic spaces allow more focus on aesthetics. The wood species also matters, as different woods absorb stain differently. For those sensitive to chemicals, low-VOC (volatile organic compounds) options are available.

Types of Wood Stains for Floors

- Oil-based stains: The traditional choice, known for deep penetration and rich color that improves wood grain. Their slow drying time allows for even application, but they have a strong odor (high VOCs) and require mineral spirits for cleanup.

- Water-based stains: Increasingly popular due to fast drying times and low odor. They are great for occupied homes and won’t alter the wood’s color over time. The fast drying requires efficient work to avoid lap marks.

- Gel stains: Problem-solvers that sit more on the surface, making them ideal for blotch-prone woods like pine. They provide a more uniform color and are great for covering minor imperfections.

Types of Floor Varnishes

Polyurethane varnishes are the standard for hardwood floors, available in two main types:

- Oil-based polyurethane: The champion of durability, creating a tough finish that resists heavy traffic. It adds a warm, amber glow that deepens over time. However, it has a strong odor and a long drying time.

- Water-based polyurethane: Offers impressive durability with a crystal-clear finish that doesn’t yellow. Its low odor and quick drying time make it a favorite for many projects, allowing multiple coats in a single day. While it dries to the touch quickly, it takes longer to fully cure than oil-based poly.

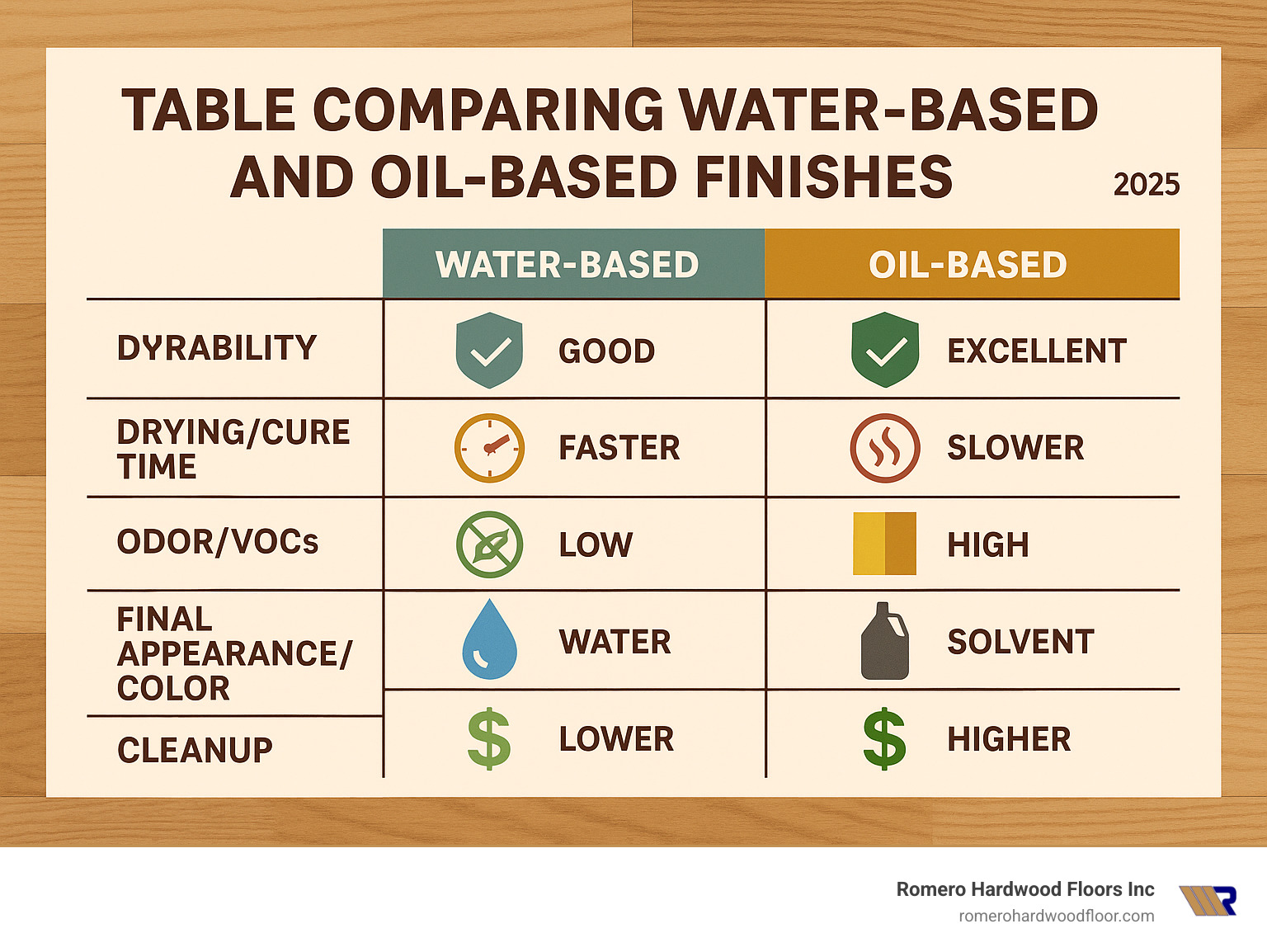

Water-Based vs. Oil-Based: A Head-to-Head Comparison

| Feature | Water-Based Finishes | Oil-Based Finishes |

|---|---|---|

| Durability | Good to excellent; modern formulations are very robust. | Excellent; known for their superior toughness and abrasion resistance, especially for high traffic. |

| Drying Time | Fast (1-4 hours per coat); allows for multiple coats in a day. | Slow (8-24 hours per coat); typically 1-2 coats per day. |

| Cure Time | Slower (1-3 weeks for full cure); needs careful treatment during this period. | Faster (3-7 days for full cure); can tolerate light use sooner. |

| Odor/VOCs | Low odor; lower VOC (Volatile Organic Compounds) content, better for indoor air quality. | Strong odor; higher VOC content, requires more ventilation. |

| Appearance | Dries clear, retains natural wood color; minimal ambering over time. | Dries with an amber tint, deepens wood color; can yellow significantly over time. |

| Cleanup | Easy with soap and water. | Requires mineral spirits or paint thinner. |

| Cost | Generally higher per gallon, but often fewer coats needed. | Generally lower per gallon. |

Choosing the Right Floorboard Stain and Varnish for Your Wood Type

Different woods have different personalities. Understanding your wood type is crucial for achieving the desired result.

- Oak flooring: Its open grain absorbs stain beautifully and evenly, making it compatible with a wide range of colors and any polyurethane finish.

- Pine flooring: This softer wood tends to absorb stain unevenly, leading to a blotchy look. A pre-stain wood conditioner is recommended to ensure uniform absorption. Its softness also demands a very durable varnish for protection.

- Maple flooring: Its dense, tight grain resists stain penetration, often resulting in lighter-than-expected colors. Its natural beauty is often best showcased with just a clear varnish.

Always test your chosen floorboard stain and varnish in an inconspicuous area first to avoid surprises and ensure you get the look you want.

The Ultimate Guide to Floorboard Stain and Varnish Application

A perfect floorboard stain and varnish finish requires a careful, step-by-step process. The difference between a professional look and a DIY disaster often comes down to patience and attention to detail, as each step builds on the last.

Step 1: Meticulous Preparation is Key

Preparation makes or breaks the project. If your floor isn’t properly prepared, even the best products won’t perform correctly.

- Sanding: Start with coarser grits (150-220) to remove old finishes and smooth imperfections, then move to finer grits for a surface that will absorb stain evenly. Any scratches left behind will be obvious after staining.

- Dust Removal: After sanding, vacuum thoroughly and then use a tack cloth to pick up the finest dust particles. A single speck of dust can create a visible bump in the final finish.

- Cleaning and Repairs: Fill any cracks with wood filler and give the floor a final cleaning to remove any grease or contaminants that could prevent proper adhesion.

For more details on this crucial phase, see our floor sanding and refinishing services.

Step 2: Applying the Stain Evenly

This step requires a methodical approach. Use a rag or specialized applicator for the best control, and a brush for edges. To avoid lap marks, work in sections and maintain a “wet edge,” always applying new stain next to a still-wet area. Work with the grain, not against it.

Wipe off excess stain promptly with clean cloths. The longer the stain sits, the darker it gets. For blotch-prone woods like pine, use a pre-stain wood conditioner to help the stain absorb more evenly.

Step 3: Applying the Varnish for a Flawless Finish

Once the stain is completely dry, it’s time for the protective varnish. Stir the varnish gently—never shake it, as this creates air bubbles. Use a lambswool applicator or foam pad for large areas and a brush for edges. Apply thin, even coats rather than one thick coat, which can bubble and dry unevenly.

Work systematically from a corner toward an exit. Lightly sand between coats with fine-grit sandpaper (around 320 grit) to remove any dust nibs and help the next coat adhere.

Step 4: Understanding Drying and Curing Times

Patience is critical here. There’s a huge difference between “dry to touch” (a few hours) and “fully cured” (ready for normal use).

- Curing is the chemical hardening process where solvents evaporate. If you can still smell the varnish, it’s still curing.

- Light traffic may be possible after 24-48 hours, but use extreme caution.

- Full cure times vary: water-based products can take 1-3 weeks, while oil-based products often cure in 3-7 days.

- Temperature, humidity, and ventilation all affect these times. Wait at least a week before cleaning and 2-4 weeks before placing heavy furniture or area rugs. The wait is worth it for a durable, beautiful floor.

DIY vs. Professional: Which Route is Right for You?

When refinishing your floors with floorboard stain and varnish, you can either tackle it yourself or hire professionals. The right choice depends on your budget, skill level, and desired quality of the final result. If you’re considering new flooring altogether, we also offer hardwood floor installation services.

The DIY Approach: Pros and Cons

- Pros: The biggest draw is cost savings, as you’re only paying for materials and tool rentals. There’s also the personal satisfaction of completing the project yourself and learning a new skill.

- Cons: There is a real potential for mistakes, such as improper sanding or uneven application, which can be costly and difficult to fix. The project is also time-consuming, often taking a week or more of disrupted living. You’ll need to rent and learn to use specialized equipment like drum sanders and edgers.

Hiring a Professional: Pros and Cons

- Pros: You’re paying for expertise and experience. Professionals are efficient, completing the job much faster than a DIYer. They use advanced dust containment systems to minimize mess and, most importantly, guarantee their results, providing peace of mind.

- Cons: The main drawback is the higher cost. You’ll also need to work around the professional’s scheduling.

Note: Professional refinishing costs can range from $3 to $8 per square foot for basic work, with complex projects or premium finishes costing $8 to $15+ per square foot. These are general estimates based on internet data; actual prices vary by location, project complexity, and materials chosen. These are not Romero Hardwood Floors’ actual prices.

If you’re in Beverly, Chelsea, Danvers, Gloucester, Lynnfield, Malden, Manchester by the Sea, Marblehead, Medford, Melrose, Nahant, Peabody, Reading, Revere, Rockport, Salem, Saugus, Somerville, Stoneham, Swampscott, Wakefield, Winchester, Winthrop, Woburn, or our other Massachusetts service areas, we can help you decide the best route for your project.

Long-Lasting Beauty: Maintaining Your Stained and Varnished Floors

Your floorboard stain and varnish finish is a significant investment. With proper care, it can maintain its stunning appearance for decades. Consistent maintenance is the key to protecting your investment. To see examples of our finished floors, view our gallery.

Daily and Weekly Care

- Sweep or Vacuum Regularly: Use a soft brush attachment to remove abrasive dirt and grit that can scratch the finish.

- Use the Right Cleaner: Clean with a pH-neutral cleaner specifically designed for wood floors. Avoid harsh chemicals, vinegar, or all-purpose cleaners.

- Damp Mop Only: Use a microfiber mop that is damp, not wet. Excessive water is hardwood’s biggest enemy and can cause warping or finish damage.

Protecting Against Damage

- Use Furniture Pads: Place felt pads under all furniture legs to prevent scratches and gouges.

- Place Area Rugs: Use rugs in high-traffic areas like entryways. Wait 2-4 weeks after finishing for the varnish to fully cure before placing them.

- Trim Pet Claws: Keep pet nails trimmed to prevent scratches.

- Protect from Sunlight: Use curtains or blinds to prevent UV rays from fading the stain and varnish over time.

Common Mistakes with Floorboard Stain and Varnish

Avoid these common pitfalls to save time and frustration:

- Skipping Preparation: A finish is only as good as the surface beneath it. Don’t cut corners on sanding and cleaning.

- Not Testing Products: Always test your stain and varnish on a hidden spot first, as wood species react differently.

- Applying Thick Coats: This leads to uneven drying, bubbles, and a weak finish. Multiple thin coats are always better.

- Rushing Drying Times: Putting furniture back too soon on an uncured finish can cause permanent marks. Patience is essential.

- Ignoring Manufacturer Instructions: Follow the product’s guidelines for temperature, humidity, and application for the best results.

Scratches are less noticeable when the stain has penetrated the wood, which is why a separate stain and varnish process is often superior.

Frequently Asked Questions about Floor Finishing

After 15 years in the flooring business, I’ve heard many of the same questions about floorboard stain and varnish. Here are answers to some of the most common concerns.

How many coats of varnish do I need for a hardwood floor?

Most hardwood floors need 2-3 coats of varnish. For typical rooms with moderate traffic, two coats are often sufficient. For high-traffic areas like kitchens and hallways, a third coat adds significant durability. However, more isn’t always better. Applying too many thick coats can prevent the finish from curing properly. Always follow the manufacturer’s recommendations for the specific product you are using.

Can I apply a new coat of varnish over an old finish?

Yes, but only if the existing finish is in good condition. This process, known as a “screen and recoat” or “buff and coat,” is a great way to refresh floors without a full refinish. It involves lightly sanding the surface to create a bond for the new varnish. However, if the existing finish is peeling, worn through to bare wood, or has deep scratches, it must be completely sanded off before applying a new finish. A full refinishing is necessary if more than 10-15% of the floor shows significant wear.

How do I fix a mistake after the varnish has dried?

Most mistakes are fixable. For small imperfections like dust nibs, you can often scrape them level with a razor blade and do a light touch-up. For larger problems like drips or bubbles, let the coat cure completely (which can take days), then sand the affected area smooth with fine-grit sandpaper (around 320 grit) and apply another thin, even coat of varnish. It’s always easier to prevent mistakes through careful preparation than to fix them later.

Conclusion

Choosing the right floorboard stain and varnish is about creating a foundation that is both beautiful and durable. Success depends on understanding the distinct roles of stain (for color) and varnish (for protection) and selecting the products that best fit your home, lifestyle, and aesthetic goals.

The balance between durability and aesthetics is key. A penetrating stain that improves the wood’s natural grain, protected by a quality varnish, creates a floor that can handle daily life while adding long-term value to your home.

At Romero Hardwood Floors Inc., we’ve helped hundreds of homeowners across Massachusetts, from Revere to Salem, transform their spaces since 2006. We’ve seen how the perfect finish can completely change the feel of a home.

Whether you choose a DIY approach or trust a professional, selecting the right products is the first step toward a stunning result. A beautifully finished floor not only improves your home’s appearance but also protects your investment for years to come.

Ready to transform your floors? Request an estimate for your flooring project today!

Like us on Facebook!