Hardwood floor underlayment options: Ultimate Guide 2025

Why the Right Underlayment Makes All the Difference

Hardwood floor underlayment options include felt, foam, cork, and rubber materials that serve as the protective foundation between your subfloor and finished hardwood. Here are the main types and their key benefits:

Main Underlayment Types:

- Felt – Traditional, breathable, good sound dampening, requires separate vapor barrier

- Foam – Lightweight, built-in vapor barrier, budget-friendly, easy installation

- Cork – Eco-friendly, excellent sound absorption, natural antimicrobial properties

- Rubber/Fiber – Superior soundproofing, high durability, best for high-traffic areas

Key Benefits:

- Sound reduction (footstep and impact noise)

- Moisture protection (prevents warping and mold)

- Thermal insulation (warmer floors)

- Floor cushioning (comfort underfoot)

- Smooths minor subfloor imperfections

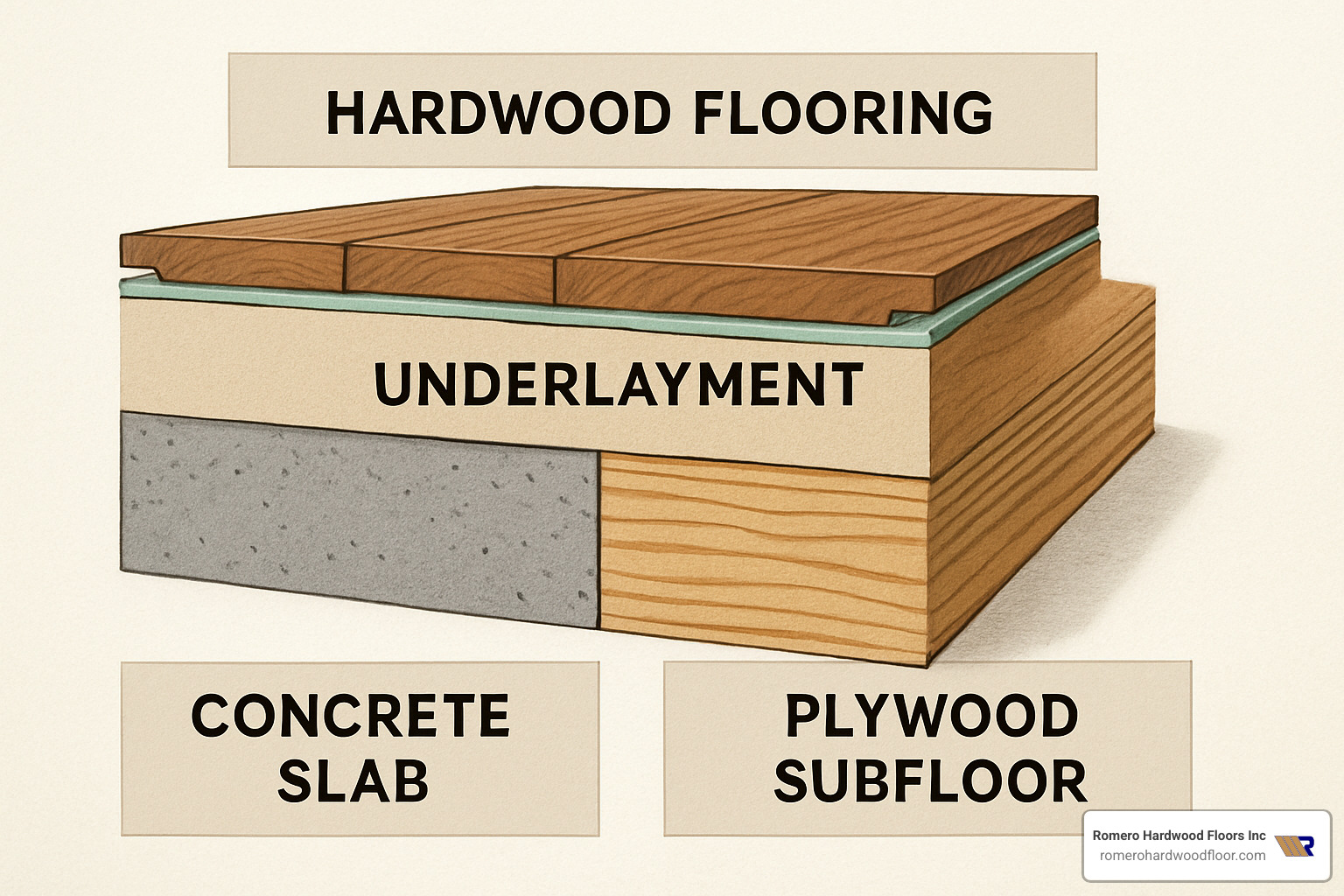

Whether you’re installing solid hardwood over plywood or engineered floors over concrete, the right underlayment protects your investment and improves comfort. The choice depends on your subfloor type, room location, and specific performance needs.

As Francisco Romero, owner of Romero Hardwood Floors Inc., I’ve guided countless homeowners through hardwood floor underlayment options during my 15+ years in the flooring industry. My experience has shown that proper underlayment selection is crucial for long-term floor performance and customer satisfaction.

Easy Hardwood floor underlayment options glossary:

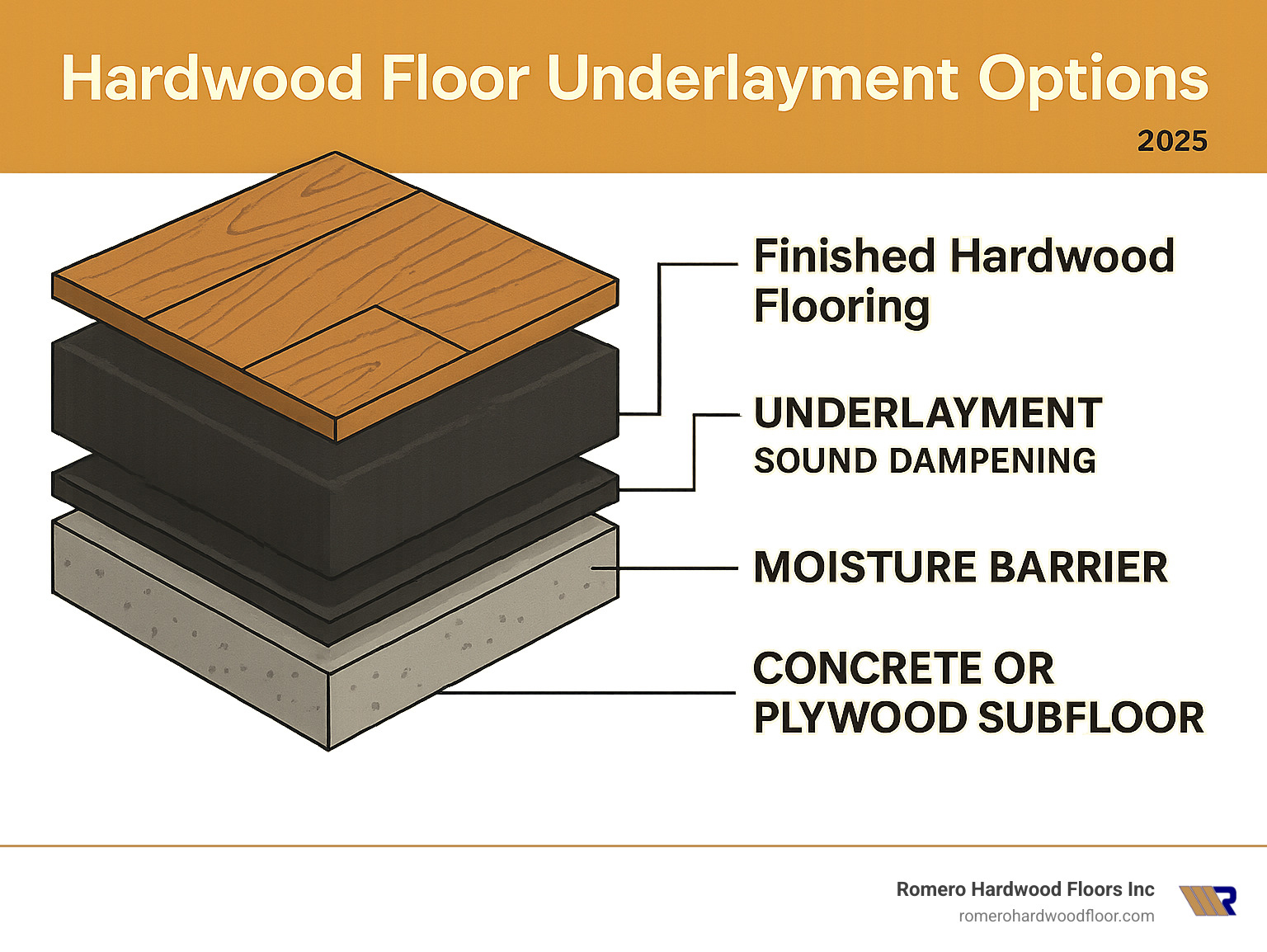

What is Hardwood Floor Underlayment and Why is it Essential?

Hardwood floor underlayment is that hidden hero living between your subfloor and beautiful hardwood – and trust me, it’s working harder than you might think. After installing floors in Massachusetts homes for over 15 years, I’ve learned that this protective layer is what separates a good floor from a great one that lasts decades.

Think of underlayment as your floor’s foundation. It’s the unsung champion that handles everything from moisture protection to sound reduction, all while making your floors more comfortable underfoot. Without it, even the most expensive hardwood can develop problems that’ll have you calling for repairs sooner than you’d like.

The magic happens in six key ways: sound reduction keeps your family (and neighbors) happy, moisture protection prevents warping and mold, thermal barrier properties make floors warmer, floor cushioning adds comfort, and it smooths out those annoying subfloor imperfections that can telegraph through your beautiful new hardwood.

Here’s something that might surprise you – quality underlayment can increase your floor’s warmth by up to 15%. That means cozier mornings and potentially lower heating bills. Not bad for something most people never see!

The durability and longevity benefits are where underlayment really shines. It acts as a protective buffer that absorbs daily wear and tear, helping your hardwood floors maintain their beauty for years to come.

The Role of Underlayment in Sound Reduction

Nobody wants to sound like a herd of elephants when walking across their beautiful hardwood floors. That’s where underlayment becomes your acoustic superhero, tackling both footstep noise and impact noise that can drive everyone in your home (especially those downstairs) absolutely crazy.

When someone drops something or walks across floors without proper underlayment, that sound travels through your floor system like it’s on a mission. This is especially problematic in multi-story homes and condos where noise between units can strain neighborly relationships.

Quality underlayment absorbs both impact noise (think footsteps and dropped toys) and airborne noise (conversations and music). The industry measures this effectiveness using IIC rating (Impact Insulation Class) and STC rating (Sound Transmission Class) – fancy terms that basically tell you how well your floor will keep the peace.

Good underlayments typically achieve IIC ratings of 70+ and STC ratings of 60+, both exceeding building code minimums of 50. For example, recycled rubber underlayments can hit IIC ratings of 73 and STC ratings of 66, with a Delta IIC improvement of 23. Translation? Your floating floors will sound solid and quiet, just like traditional nailed-down hardwood.

In my experience serving communities from Beverly to Winchester, proper sound absorption is especially crucial for homeowners in condos where noise transmission can become a real headache. The right underlayment transforms your floors into a quiet living space that everyone can enjoy.

How Underlayment Provides Critical Moisture Protection

Moisture is hardwood flooring’s arch-nemesis, and underlayment serves as your first line of defense in this ongoing battle. Concrete subfloors naturally emit moisture vapors that can wreak havoc on your floors if not properly managed – and even above-grade installations face moisture challenges from seasonal humidity changes.

The secret weapon here is the vapor barrier – typically a 6-mil polyethylene film that prevents moisture from reaching your hardwood. This moisture barrier is absolutely critical in basements, crawlspaces, and over concrete slabs where ground moisture loves to migrate upward and cause trouble.

Here’s the key: different situations need different approaches. For concrete subfloors, you need an impermeable barrier that completely blocks moisture transmission. For plywood subfloors, a semi-permeable underlayment allows natural moisture exchange while preventing bulk water damage.

Proper moisture protection prevents those dreaded hardwood problems like warping, cupping, crowning, and mold and mildew growth. I’ve seen too many beautiful hardwood floors damaged by moisture issues that could have been easily prevented with the right hardwood floor underlayment options.

The bottom line? Investing in quality moisture protection now saves you from expensive repairs later. More about industry standards from the NWFA provides additional guidance on proper moisture management techniques.

A Guide to Common Hardwood Floor Underlayment Options

Choosing the right underlayment can feel overwhelming with so many options available. After nearly two decades of installing hardwood floors throughout Massachusetts, I’ve worked with every type of underlayment material and seen how each performs in real-world conditions.

The four main hardwood floor underlayment options each have distinct characteristics that make them suitable for different situations. Understanding these differences will help you select the best material for your specific project needs and budget.

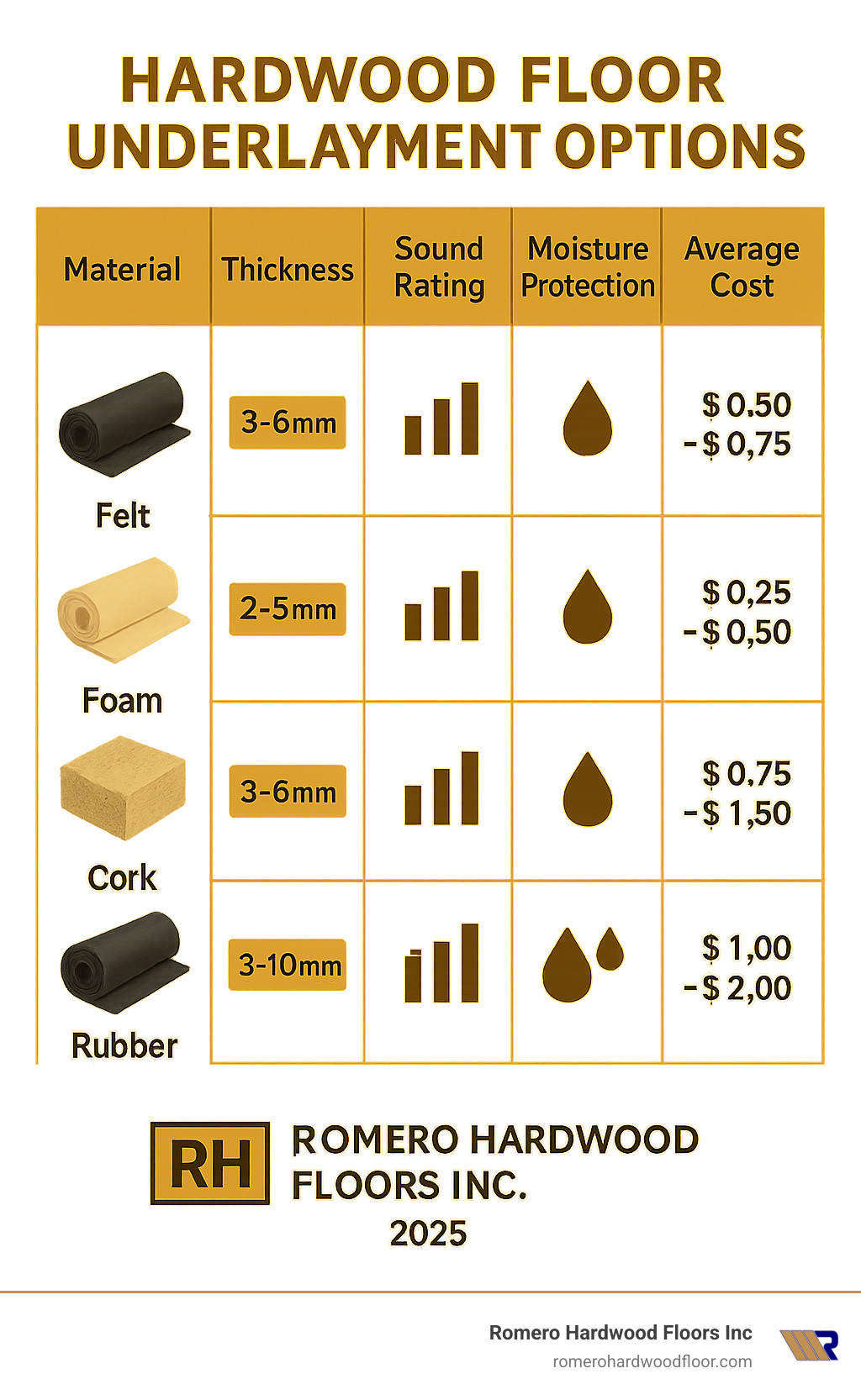

Material density and thickness play crucial roles in performance. Thicker isn’t always better – the goal is finding the right balance of cushioning, sound control, and stability for your particular hardwood flooring type and installation method.

Felt Underlayment

Felt underlayment is the traditional choice that many flooring professionals still prefer for nail-down solid hardwood installations. Made from recycled fibers, felt offers a winning combination of breathability, sound dampening, and reliable cushioning that’s stood the test of time.

The biggest advantage of felt is its natural breathability. Unlike some synthetic materials, felt allows air circulation while still providing excellent sound absorption. This air movement helps prevent moisture buildup that can lead to mold and mildew problems down the road.

Felt provides solid cushioning without being too soft, creating a stable foundation for your hardwood floors. It’s also cost-effective compared to premium options, making it a smart choice for budget-conscious projects where performance matters.

The main drawback is that felt requires a separate vapor barrier when installed over concrete subfloors or in moisture-prone areas like basements. This adds an extra step to the installation process, but it’s necessary for proper moisture protection in these situations.

Foam Underlayment

Polyethylene foam has become one of the most popular hardwood floor underlayment options because it’s lightweight, easy to install, and budget-friendly. Many foam products include a built-in vapor barrier, which makes them perfect for installations over concrete subfloors.

The convenience factor can’t be overstated. Foam rolls out quickly and cuts easily with a utility knife, speeding up installation time. The built-in vapor barrier eliminates the need for separate moisture protection in most situations, simplifying the process.

Foam provides good insulation properties, making floors warmer and more comfortable underfoot. It’s particularly effective at accommodating the natural expansion and contraction of hardwood floors, reducing friction between the floor and subfloor that can cause squeaking.

High-density foam options deliver the best performance, offering superior cushioning while maintaining the structural integrity your hardwood flooring needs. The key is choosing quality foam that won’t compress over time and lose its effectiveness.

Cork Underlayment

Cork underlayment represents the eco-friendly premium option that appeals to environmentally conscious homeowners. Made from renewable cork oak bark, it offers excellent sound absorption, natural antimicrobial properties, and superior thermal insulation.

The cellular structure of cork provides exceptional sound dampening – often outperforming foam or felt options. This makes cork ideal for upstairs bedrooms or any area where noise control is a priority. The natural antimicrobial properties mean cork resists mold, mildew, and bacteria growth without requiring chemical treatments.

Cork’s thermal properties make a noticeable difference in floor comfort. Floors feel warmer underfoot, which can improve comfort while potentially reducing heating costs. The firm support cork provides works well with both solid and engineered hardwood installations.

While cork typically costs more than foam or felt, its durability and performance often justify the investment. I’ve seen cork underlayment maintain its properties for decades, making it a smart long-term choice for quality-focused projects.

Rubber and Fiber Underlayment

Rubber and fiber underlayments are the best of the hardwood floor underlayment options for sound control and represent the premium choice for demanding applications. Often made from recycled materials, these products offer superior soundproofing capabilities and exceptional longevity.

The superior sound absorption of rubber makes it ideal for high-traffic areas and multi-story homes where maximum noise reduction is needed. These materials excel in situations like upstairs bedrooms, condos, and apartments where sound transmission between floors can be a real problem.

Rubber underlayments provide excellent moisture resistance and maintain their performance characteristics over time without compression or degradation. This durability makes them perfect for high-traffic hallways, busy family rooms, and commercial applications.

While rubber underlayments typically represent the highest cost option, they deliver best performance for demanding situations. The investment pays off in superior sound control, long-term durability, and peace of mind. Learn about a specific moisture control product

How to Choose the Best Underlayment for Your Hardwood Floors

Choosing the right hardwood floor underlayment options isn’t just about picking the cheapest material – it’s about matching the underlayment to your specific project needs. After installing thousands of square feet of hardwood flooring throughout Massachusetts, I’ve learned that the “best” underlayment depends entirely on your unique situation.

The decision factors that matter most are your subfloor type, room location, and the hardwood you’re installing. Get these considerations right, and your floors will perform beautifully for decades. Miss the mark, and you might face squeaks, moisture damage, or noise complaints from family members below.

Consider Your Subfloor: Concrete vs. Plywood

Your subfloor type is the most important factor when selecting underlayment. Concrete slabs and plywood subfloors have completely different moisture characteristics and support requirements.

Concrete naturally emits moisture vapor that can damage hardwood floors if not properly controlled. You need an impermeable vapor barrier that completely blocks moisture transmission. This means choosing foam underlayments with built-in vapor barriers or installing separate moisture protection under felt products.

Before any concrete installation, we always test moisture levels using calcium chloride tests. Acceptable levels are typically below 3 pounds per 1,000 square feet per 24 hours. Higher readings mean you need to address moisture issues before installing any flooring.

Plywood subfloors offer more flexibility in underlayment choice. These wood subfloors actually benefit from breathable underlayments that allow natural moisture exchange. Felt works beautifully here, providing sound dampening while letting the wood subfloor breathe naturally.

The key with plywood is ensuring it’s properly fastened and level before underlayment installation. Minor imperfections can be leveled by quality underlayment, but major issues need correction first. More info about our hardwood floor installation services

Factor in Room Location and Use

Where you’re installing hardwood significantly influences your underlayment choice. Upstairs bedrooms need sound-dampening properties to reduce footstep noise to rooms below. Nobody wants to hear every step from the family room above their bedroom.

High-traffic hallways and family rooms demand durable underlayments that maintain their cushioning properties over time. These areas see constant foot traffic, so cheaper options that compress quickly will leave you with squeaky, uncomfortable floors.

Basement installations require moisture-resistant underlayments with vapor barriers, regardless of your hardwood type. Ground moisture can migrate upward through concrete, making moisture protection absolutely critical.

For kitchens (where hardwood isn’t typically recommended but sometimes installed), choose underlayments with antimicrobial properties and superior moisture resistance. Spills happen, and you need protection that prevents mold and mildew growth.

Homes with radiant heat systems need specially approved underlayments that maintain their properties under temperature fluctuations. These products won’t emit odors when heated and can handle the thermal cycling. Maximum recommended floor temperatures are typically around 81°F.

Match Underlayment to Your Hardwood Type

Different hardwood types have varying support requirements that directly impact underlayment selection. Solid hardwood installations typically perform best with felt or rubber underlayments that provide firm, stable support without excessive give.

Engineered hardwood often works well with foam underlayments that accommodate more movement. The layered construction of engineered floors handles slight deflection better than solid wood.

Softer wood species like cherry benefit from cork or rubber underlayments that provide extra cushioning and support. These materials help prevent denting and extend the floor’s lifespan in active households.

Harder woods like oak and hickory can work with a wider range of underlayment options. Their natural durability means you can focus more on sound control and comfort rather than protection.

Always check your hardwood flooring manufacturer’s recommendations and warranty requirements. Some manufacturers specify particular underlayment types or brands. Using non-approved products can void your warranty entirely – something we’ve seen happen to homeowners who tried to save a few dollars on underlayment. See examples of different wood floors in our gallery

Understanding Average Costs

Underlayment costs vary significantly based on material, thickness, and features. These are industry average costs and do not reflect pricing for Romero Hardwood Floors. Costs can range from $0.30 to over $2.50 per square foot depending on material, thickness, and features.

Basic foam underlayment typically runs $0.30 – $0.90 per square foot, making it the most budget-friendly option. Felt underlayment costs $0.40 – $1.20 per square foot and offers good middle-ground performance.

Cork underlayment ranges from $0.60 – $1.80 per square foot, reflecting its premium eco-friendly properties and superior sound absorption. Premium rubber and fiber options cost $0.80 – $2.50+ per square foot but deliver the best performance for demanding applications.

Specialty moisture barriers add $0.25 – $0.75 per square foot when needed as separate products. While these costs might seem significant, underlayment represents a small percentage of your total flooring investment.

Quality underlayment appropriate for your specific situation is an investment in your floor’s longevity and your home’s comfort. I’ve seen too many beautiful hardwood installations compromised by cheap underlayment choices that seemed smart at purchase time but caused problems years later.

Frequently Asked Questions about Hardwood Underlayment

Is underlayment always required for hardwood floor installation?

While not strictly mandatory for nail-down solid hardwood over a plywood subfloor, it is highly recommended for sound, moisture, and comfort benefits. It is almost always required for floating engineered floors and any installation over concrete. Always check the flooring manufacturer’s warranty.

Here’s the reality from our years of experience: even when manufacturers don’t require underlayment, we’ve seen the dramatic difference it makes in floor performance. The sound reduction alone makes it worthwhile – especially when you’re trying to sleep upstairs while someone’s walking around downstairs at midnight!

For floating engineered floors, underlayment isn’t just recommended – it’s essential for proper installation. These floors rely on the underlayment for stability and to prevent the clicking and hollow sounds that can occur without proper support.

The modest additional cost of underlayment typically pays for itself through improved comfort and longer floor life. We always recommend it to our clients, even when it’s technically optional.

How thick should my hardwood underlayment be?

Underlayment thickness typically ranges from 2mm to 6mm. Thicker underlayment offers more sound and thermal insulation but can create too much flex. It’s crucial to follow the hardwood flooring manufacturer’s specifications to avoid voiding the warranty.

Most residential installations use 2-3mm underlayment for optimal performance. This thickness provides excellent sound dampening and moisture protection without creating instability. We’ve found this range works well for both solid and engineered hardwood installations.

Thicker options (4-6mm) may be appropriate for commercial applications or specific sound control requirements, but always verify compatibility with your flooring system. Too much thickness can cause the floor to feel “bouncy” or unstable, which nobody wants.

The key is finding the sweet spot – enough thickness for performance benefits without compromising the structural integrity of your floor installation.

Can I use two layers of underlayment for extra soundproofing?

No, stacking underlayment is not recommended. It can create an unstable foundation for the hardwood, causing the floor’s locking system to fail and leading to excessive movement, squeaking, and potential damage.

We understand the temptation – if one layer is good, two must be better, right? Unfortunately, that’s not how it works with hardwood floor underlayment options. Double-layering creates too much give in the floor system, which can cause boards to separate or locking mechanisms to fail over time.

If maximum sound control is needed, choose a single high-performance underlayment designed for superior acoustic properties rather than doubling up on standard products. Premium rubber or cork underlayments often provide better sound reduction than two layers of basic foam.

The solution for demanding sound control applications is investing in a single, high-quality underlayment rather than trying to stack multiple layers. Professional consultation can help identify the best single-layer solution that meets your specific soundproofing needs without compromising floor stability.

Get the Foundation Right for a Floor That Lasts a Lifetime

Getting your hardwood floor underlayment options right from the start makes all the difference between a floor that performs beautifully for decades and one that develops problems down the road. The foundation you choose today directly impacts your daily comfort, long-term durability, and overall satisfaction with your hardwood investment.

After 15+ years in the flooring business, I’ve seen how the right underlayment choice transforms a good flooring project into a great one. At Romero Hardwood Floors Inc., we’ve learned that every home tells a different story – from the moisture challenges in a Revere basement to the sound control needs in a multi-family property in Somerville.

Professional guidance matters when selecting underlayment because local conditions, building codes, and specific flooring systems all influence the best choice for your project. What works perfectly in a modern condo might not be ideal for a historic home, and understanding these nuances comes from experience working throughout Massachusetts communities.

Whether you’re dealing with a concrete slab that needs serious moisture protection or a plywood subfloor where sound dampening is the priority, the right underlayment selection supports your entire flooring investment. We’ve seen too many beautiful hardwood floors compromised by underlayment choices that seemed fine initially but caused problems later.

Expert installation goes hand-in-hand with proper material selection. Even the best underlayment won’t perform as intended if it’s not installed correctly. Our team understands the specific challenges of New England installations – from dealing with seasonal humidity changes to meeting sound transmission requirements in condos and multi-family properties.

The investment in quality underlayment and professional installation pays dividends in comfort, performance, and peace of mind. Your floors will feel solid underfoot, sound quieter to family members below, and maintain their beauty longer when built on the right foundation.

Don’t leave something this important to guesswork. Trust the experts who understand your local conditions and have the experience to match the right underlayment to your specific needs and budget. Request an estimate for your flooring project

The right foundation today means enjoying beautiful, comfortable, and quiet hardwood floors for years to come. That’s the kind of lasting value we’re proud to deliver at Romero Hardwood Floors Inc.