Underlayment for floating floors: Top 3 Crucial Picks

Why Underlayment is the Unsung Hero of Your Floating Floor

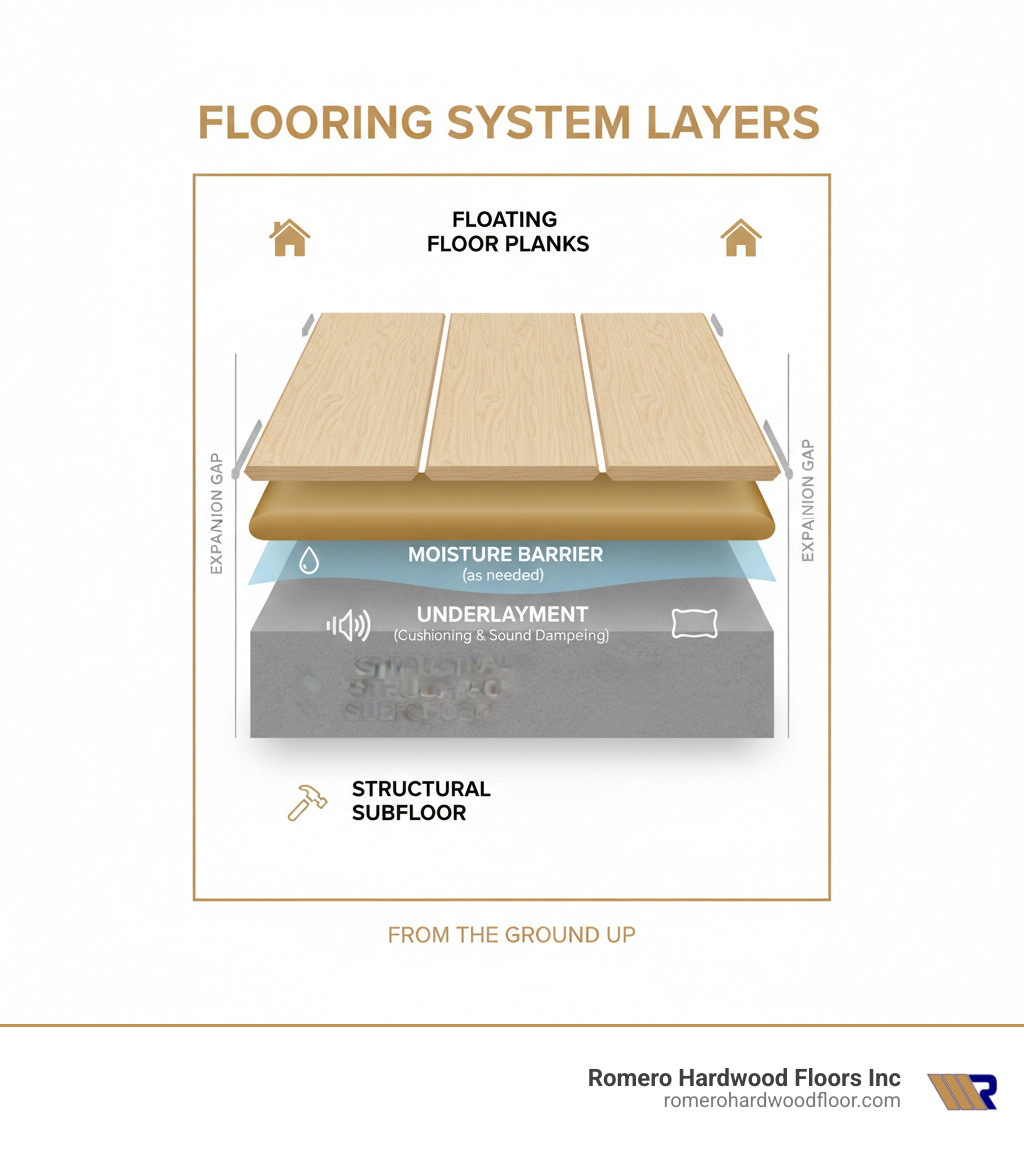

Underlayment for floating floors is the thin protective layer installed between your subfloor and the finished flooring material. It serves multiple critical functions that directly impact your floor’s performance, comfort, and lifespan.

Key functions of underlayment:

- Sound Reduction – Dampens footfall noise and impact sounds

- Moisture Protection – Acts as a vapor barrier to prevent water damage

- Cushioning – Adds comfort underfoot and allows natural floor expansion

- Subfloor Correction – Smooths minor imperfections for a level surface

- Thermal Insulation – Provides additional warmth and energy efficiency

Most floating floor installations—including laminate, vinyl plank, and engineered wood—require underlayment where it’s not pre-attached to the flooring. While it’s hidden beneath your beautiful new floors, this layer is essential for maintaining the appearance, feel, and durability of your investment.

As Francisco Romero, owner of Romero Hardwood Floors Inc., I’ve installed countless floating floors over the past 15 years, and I can tell you that proper underlayment for floating floors makes the difference between a floor that performs beautifully for decades and one that develops problems within months. In this guide, I’ll walk you through our top product picks and the key factors to consider when selecting underlayment for your specific project.

The Core Functions: What Underlayment Does for Your Floor

Many homeowners ask if underlayment is necessary for a floating floor. The answer is almost always yes. Underlayment for floating floors isn’t just an optional extra; it’s the foundation that makes everything else work properly. Think of it as the foundation for your floor—it’s essential for proper performance.

Sound Reduction

A common complaint about floors without underlayment is a hollow, loud sound. Quality underlayment for floating floors acts as a sound buffer, absorbing vibrations and dramatically reducing noise. This is crucial in multi-level homes, apartments, and condos to prevent noise transfer between floors.

Sound performance is measured with two key ratings: Impact Insulation Class (IIC) for impact sounds (footsteps, dropped items) and Sound Transmission Class (STC) for airborne sounds (voices, music). Premium underlayments like felt, cork, and rubber offer high IIC and STC ratings, creating a significantly quieter home.

Moisture Protection

Moisture is the number one enemy of a floating floor. Underlayment for floating floors often includes a built-in vapor barrier or works with a separate one to shield your flooring from moisture. This is critical when installing over concrete slabs, in basements, or in any area prone to humidity.

For concrete, a 6-mil polyethylene sheeting is essential. Some underlayments simplify this with an integrated moisture barrier. A concrete slab must be at least 60 to 90 days old, and we test to ensure vapor emission doesn’t exceed 5-7 pounds per 1,000 sq. ft. in 24 hours, with relative humidity at or below 75%. For wood subfloors, moisture content should be between 6% and 12% and never exceed 14%.

Cushioning and Comfort

Underlayment adds a subtle cushioning effect, making floors more comfortable to walk and stand on. More importantly, this cushioning allows the floating floor to expand and contract naturally with changes in temperature and humidity. This prevents stress on the locking system that can lead to gaps or buckling.

Thermal Insulation

In Massachusetts, cold winter floors are a common issue. Good underlayment adds a layer of thermal insulation, which can increase floor warmth by as much as 15%. This improves comfort and can lead to energy savings as your heating system works less, making your home feel cozier during our long winters.

Subfloor Imperfection Correction

No subfloor is perfectly flat. Underlayment helps bridge minor irregularities, creating a smoother surface for your floating floor. This prevents creaking, flexing, and damage to the flooring’s locking system over time.

However, underlayment is not a fix for major issues. Subfloor flatness must be within 3/16″ over a 10-foot span. Significant dips or humps must be leveled before installation. Think of it as a finishing touch for subfloor prep, not a replacement for it.

For more detailed guidance on choosing the right underlayment for your specific situation, check out our comprehensive guide on hardwood floor underlayment options. It covers everything you need to know to make an informed decision for your project.

Choosing the Best Underlayment for Floating Floors

Picking the right underlayment for floating floors is simpler than it seems. Your decision comes down to two things: your flooring type and your subfloor. A laminate floor on a wood subfloor has different needs than luxury vinyl plank over a basement concrete slab.

| Underlayment Type | Sound Dampening | Moisture Protection | Cost | Best Use Cases |

|---|---|---|---|---|

| Standard Foam | Basic | Minimal (requires separate barrier for concrete) | Low | Laminate, engineered wood over wood subfloors. Provides basic cushioning and thermal properties. |

| Combination (2-in-1) | Moderate to Good | Excellent (built-in vapor barrier) | Medium | Laminate, vinyl plank, engineered wood over concrete subfloors or in high-moisture areas like basements. Simplifies installation by combining underlayment and vapor barrier. |

| Premium Felt/Rubber/Cork | Superior (high IIC/STC ratings) | Good (often includes vapor barrier or is naturally resistant) | High | High-end engineered hardwood, luxury vinyl plank, in noise-sensitive environments (condos, multi-level homes). Offers excellent cushioning, durability, and acoustic performance. |

Our Pick for Standard Applications: Foam Underlayment

Standard foam underlayment is a reliable and affordable choice for most residential projects. Made from polyethylene or polypropylene and typically 1/8-inch thick, it provides essential cushioning, smooths minor subfloor imperfections, and adds some thermal insulation. We recommend it for laminate flooring and engineered wood over wood subfloors in areas where moisture isn’t a major concern.

Crucially, standard foam is not a moisture barrier. When installing over concrete, you must use a separate 6-mil polyethylene vapor barrier first to prevent moisture damage.

If you’re leaning toward laminate and want expert guidance on both the flooring and the foundation beneath it, we’d love to help. Learn more about laminate flooring installation and how we approach every project with care.

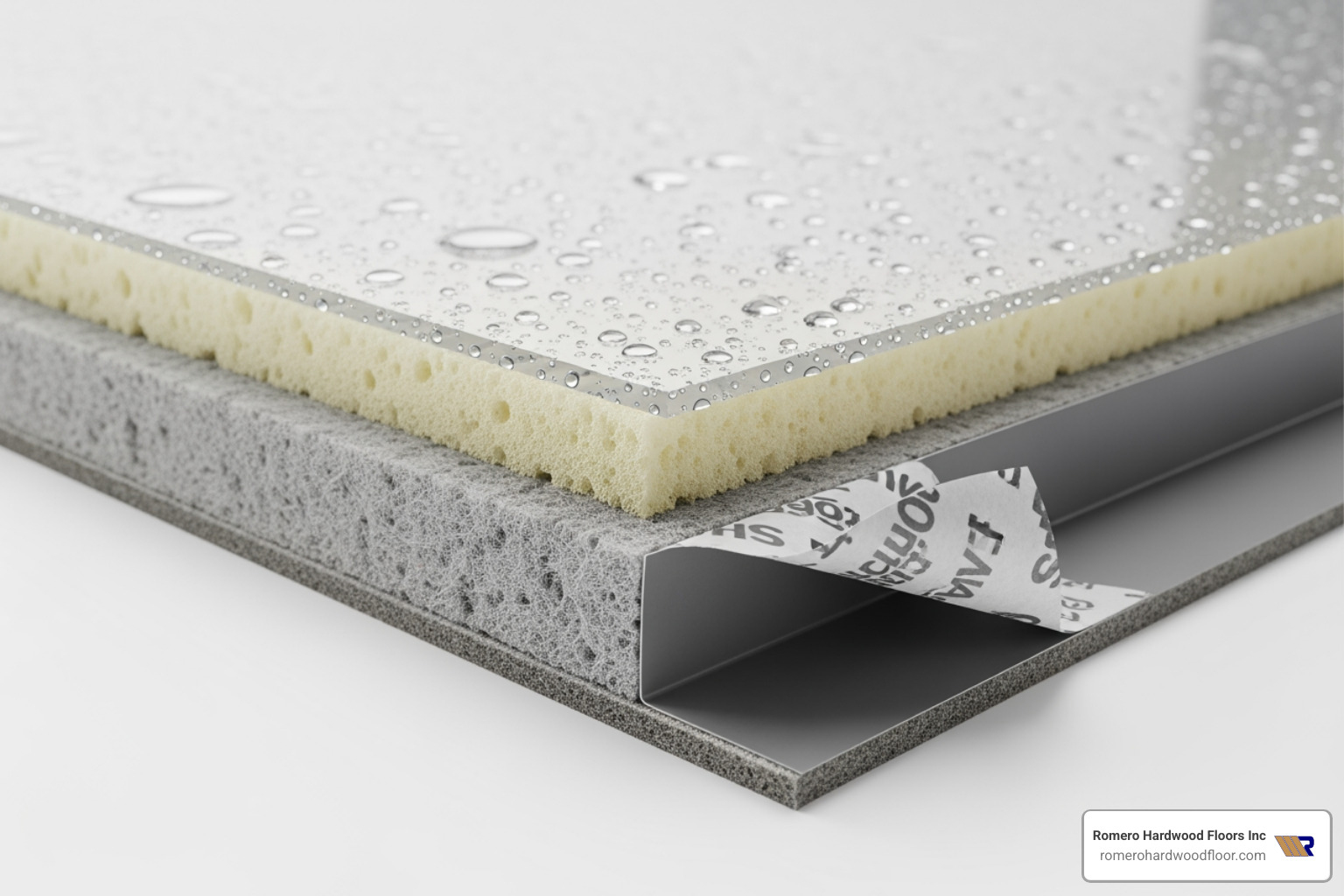

Our Pick for Concrete and Basements: Combination Underlayment

For concrete subfloors and basements, a 2-in-1 combination underlayment is the best choice, as it includes a built-in moisture barrier. Concrete constantly releases moisture vapor, which can warp, buckle, or cause mold on unprotected floors. These products feature a vapor barrier film to block moisture while providing cushioning and sound-dampening. Many include an overlap film and adhesive strips for easy, seamless installation.

While the cost is slightly higher than basic foam, it prevents costly moisture damage down the road. For more detailed guidance on concrete installations, take a look at our comprehensive guide: Read our guide on installing floors on concrete.

Our Pick for Premium Performance: Felt, Rubber, or Cork Underlayment

For high-end engineered hardwood or in noise-sensitive areas like condos, premium underlayment (felt, rubber, or cork) is a worthwhile investment. These materials offer superior sound absorption with high IIC and STC ratings for a dramatically quieter floor. They also provide a more luxurious, comfortable feel underfoot.

Their key advantage is durability. These dense, crush-proof materials maintain their support and cushioning under heavy furniture and foot traffic, unlike cheaper foams that can compress over time. For cork, look for a Shore A Hardness rating of 60 durometer or higher to ensure adequate support without being too soft.

We recommend premium options for luxury vinyl plank, high-end engineered hardwood, and any situation where noise reduction and long-term performance are critical. The upfront cost is justified by the improved comfort, acoustics, and durability.

If you’re planning an engineered hardwood project and want to ensure every detail is perfect from the subfloor up, let’s talk. Explore our engineered hardwood flooring services and find how we create floors that look stunning and perform beautifully for decades.

Installation Essentials: Prep and Best Practices

Proper subfloor preparation is the bedrock of a successful floating floor installation. Even the best underlayment for floating floors can’t compensate for a poorly prepped surface.

Subfloor Preparation

Before unrolling underlayment, get your subfloor in perfect shape. It must be completely clean and dry, so sweep and vacuum all dust and debris.

Moisture testing is non-negotiable. For concrete, the slab must be fully cured (typically 60-90 days). Test to ensure relative humidity is at or below 75% and moisture vapor emissions don’t exceed 5-7 pounds per 1,000 sq. ft. in 24 hours. Higher readings require additional moisture barriers. For wood subfloors (OSB or plywood), the moisture content must be between 6% and 12%, and never exceed 14%.

The flatness check is critical. Deviations should not exceed 3/16 inch over a 10-foot radius or 1/8 inch over a 6-foot span. Use a long straightedge to find high and low spots. Sand down high spots and fill low spots with a suitable leveling compound. Underlayment only handles minor imperfections. Also, address any loose panels or squeaks.

Finally, acclimate your flooring materials for at least 48 hours in the installation room to prevent expansion or contraction issues.

Step-by-Step Installation Guide for underlayment for floating floors

With a prepped subfloor, installing the underlayment for floating floors is straightforward.

- Unroll the underlayment in the same direction you plan to install your flooring. The vapor barrier film, if present, should face up.

- Maintain a perimeter expansion gap of 1/2 to 3/4 inch along all walls. This allows the entire floor system to move naturally and will be covered by baseboards.

- Butt seams together tightly. Never overlap the padding itself, as this creates ridges. If your underlayment has an integrated overlap flap, use it to seal the seam.

- Tape all seams with high-quality tape. This prevents shifting and ensures the integrity of the moisture barrier.

- Work in manageable sections. Lay a few rows of underlayment, then begin installing flooring over that section to keep your workspace clean and prevent damage.

For detailed instructions on installing the flooring itself after your underlayment is down, be sure to check out our complete hardwood installation guide.

Common Mistakes to Avoid with underlayment for floating floors

After 15 years in the business, I’ve seen it all. Avoid these common mistakes with underlayment for floating floors:

- Ignoring Subfloor Imperfections: Underlayment can’t fix a bumpy subfloor. Failing to level your subfloor first will result in a bouncy, noisy floor and may cause the locking system to fail.

- Overlapping Seams: This creates raised ridges that will telegraph through your finished floor, causing uneven wear. Always butt seams tightly together.

- Forgetting a Moisture Barrier on Concrete: Concrete slabs continuously emit moisture. Skipping a 6-mil poly film or a combination underlayment will almost certainly lead to warping, mold, and floor failure.

- Using the Wrong Thickness: Underlayment that’s too thick or soft creates excessive flex, which can damage the floor’s locking system and void the warranty. Always follow the flooring manufacturer’s specifications.

- Using Carpet Padding: Carpet padding is far too soft and thick for floating floors. It offers no stability, will damage the locking system, and will void your warranty. Only use products specifically designed as underlayment for floating floors.

Frequently Asked Questions about Floating Floor Underlayment

Here are answers to the most common questions we get about underlayment for floating floors.

What happens if I don’t use underlayment with a floating floor?

Skipping the underlayment for floating floors is a major mistake that leads to several problems. Your floor will feel hollow and be noisy underfoot. It becomes vulnerable to moisture damage from below, which can cause warping and mold. The flooring planks won’t have the necessary cushion to expand and contract, stressing the locking system and leading to gaps or breakage. Crucially, most flooring manufacturers will void your warranty if you skip the underlayment.

Can underlayment fix an uneven subfloor?

Underlayment can smooth over minor imperfections—slight variations like 3/16″ over 10 feet or 1/8″ over 6 feet. However, it is not a substitute for proper subfloor leveling. Major dips, humps, or waves must be corrected before installation by sanding high spots and filling low spots with a leveling compound. This is essential for a floor that looks and performs well for years.

Do I need underlayment if my flooring has a pre-attached pad?

This depends on your subfloor. If you’re installing over a wood subfloor, the pre-attached pad is usually sufficient. However, if you’re installing over a concrete slab, you still need a separate 6-mil polyethylene moisture barrier. Most pre-attached pads do not provide enough vapor protection against moisture from concrete. Always check your flooring manufacturer’s installation guidelines to ensure your warranty remains valid, especially for concrete installations.

Get the Perfect Foundation for Your Floors

As we’ve seen, underlayment for floating floors is the unsung hero that protects your investment, ensuring your floor is quiet, comfortable, and durable for years to come. The right underlayment silences footsteps, shields against moisture, smooths minor subfloor issues, and adds comfortable cushioning. Your choice—from standard foam to premium felt—directly impacts your floor’s daily performance and longevity.

At Romero Hardwood Floors Inc., we’ve spent over 15 years perfecting floating floor installations throughout Revere, MA, and surrounding communities like Beverly, Chelsea, Danvers, and Lynn. We know that proper underlayment for floating floors is the key to a floor that performs flawlessly for decades. Our commitment to using quality materials and proven techniques means your floors get the foundation they deserve.

Your new floor deserves a strong, protective base. Don’t leave this crucial element to chance. For expert installation and advice on the perfect underlayment for your project, trust the professionals who know Revere floors. Contact us today for your hardwood floor installation project and let’s build a floor that stands the test of time.

Like us on Facebook!