Top 5 best underlayment for engineered wood floating floor

The Unsung Hero Beneath Your Feet

The best underlayment for engineered wood floating floor installations typically includes one of these four types. Please note that costs are based on general market data and are not a quote for services.

- Foam with vapor barrier – Most affordable ($0.25-$0.75/sq ft), ideal for dry subfloors

- Cork underlayment – Superior soundproofing ($0.75-$2.25/sq ft), eco-friendly, natural insulation

- Felt underlayment – Dense sound blocking ($0.60-$1.80/sq ft), excellent cushioning

- Rubber underlayment – Premium durability ($1.00-$3.00+/sq ft), best for high-traffic and moisture-prone areas

For concrete subfloors or basements: Always choose an underlayment with an integrated 6-mil vapor barrier to prevent moisture damage.

When you install an engineered wood floating floor, a hidden layer of underlayment does the heavy lifting. Without it, your new floor could sound hollow, feel uncomfortable, or fail prematurely from moisture damage. This layer acts as a critical barrier between the subfloor and the engineered wood.

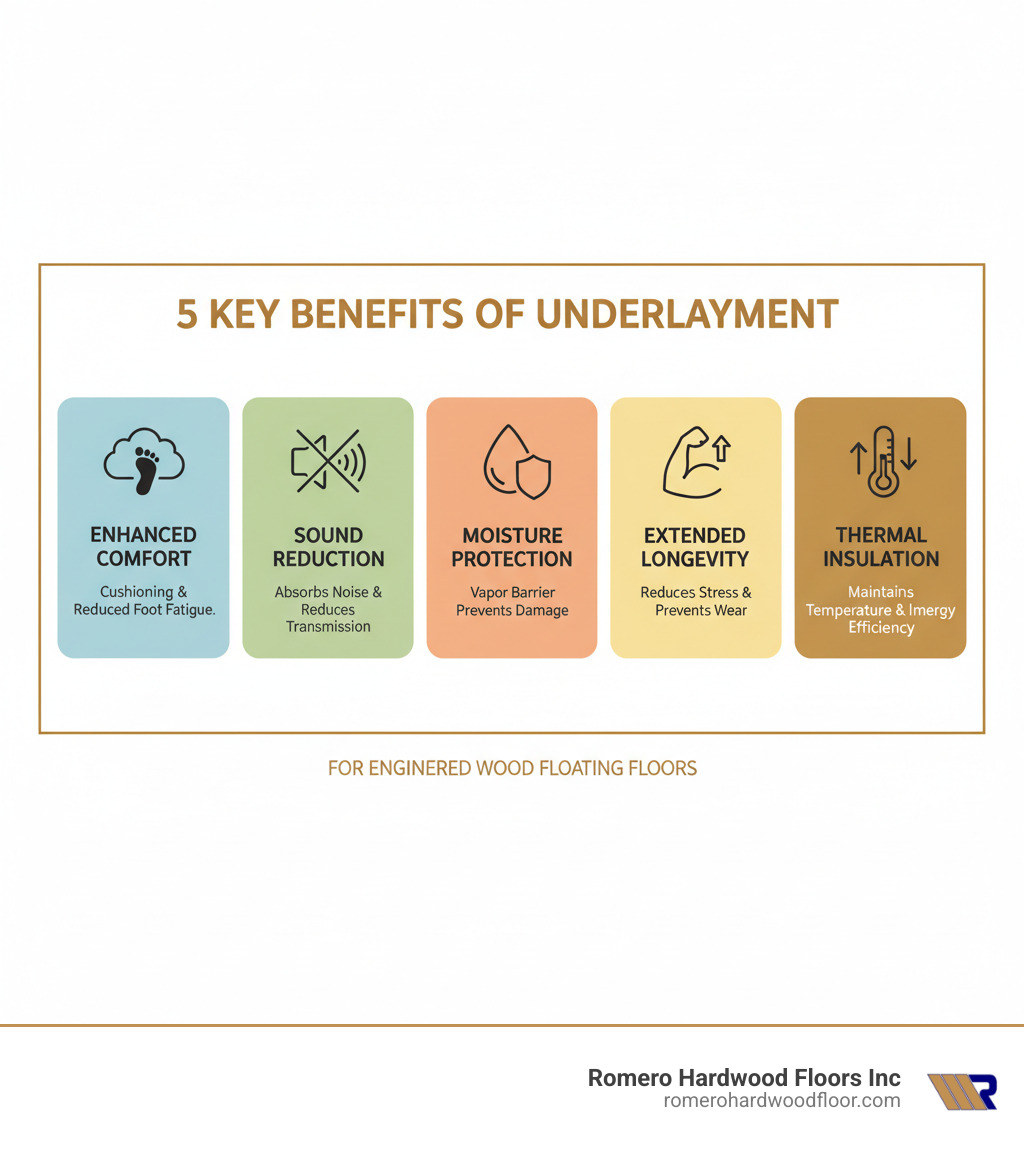

Underlayment serves four key functions for floating floors:

- Structural support – Distributes weight and minimizes uneven wear.

- Noise reduction – Reduces impact sound transmission between floors.

- Moisture protection – Blocks subfloor moisture that can warp wood.

- Thermal insulation – Helps maintain consistent indoor temperatures.

The right underlayment also allows the floating floor to expand and contract naturally with humidity changes. Since these floors aren’t nailed or glued, they “float” on the underlayment, and this movement is essential for their longevity.

However, choosing from the many options—foam, cork, felt, rubber—can be overwhelming. The wrong choice can lead to costly problems like separated joints, buckled planks, or echoing footsteps.

As Francisco Romero, owner of Romero Hardwood Floors Inc. with over 15 years of experience, I’ve seen it all. I’ve installed countless engineered wood floating floors and tested numerous underlayments. This guide shares that hands-on knowledge to help you make the right choice for your project.

A Deep Dive into Underlayment Materials

Finding the best underlayment for engineered wood floating floor means understanding what each material offers. Each type has a distinct personality, from budget-conscious workhorses to premium performers. Let’s explore the four main players to see which is your perfect match.

Here’s a quick comparison of how these materials stack up. Please note that costs are based on general market data and are not a quote for services.

| Feature | Foam | Cork | Felt | Rubber |

|---|---|---|---|---|

| Average Cost | $0.25 – $0.75 / sq ft | $0.75 – $2.25 / sq ft | $0.60 – $1.80 / sq ft | $1.00 – $3.00+ / sq ft |

| Sound Reduction | Moderate (acoustic foam better) | Excellent (natural sound absorption) | Superior (dense fibers) | Excellent (high density, impact resistant) |

| Moisture Resist. | Good (especially with vapor barrier) | Moderate (needs separate barrier often) | Moderate (can absorb if not treated) | Excellent (inherently moisture resistant) |

| Comfort | Good (light cushion) | Excellent (plush feel) | Very Good (dense, supportive cushion) | Excellent (resilient, durable cushion) |

| Eco-Friendliness | Varies (some recycled content) | Excellent (sustainable, natural) | Good (often recycled fibers) | Good (often recycled tires) |

Now let’s dig deeper into what makes each of these materials special.

Foam: The Budget-Friendly Choice for the Best Underlayment for Engineered Wood Floating Floor

Foam underlayment, made from polyethylene, is the go-to choice for homeowners seeking solid performance without a high price tag. We install it regularly because it’s a reliable and effective solution.

The biggest advantage is price. Based on general market data, foam typically runs between $0.25 and $0.75 per square foot. These are industry averages and not a quote for services. Foam is also easy to install—it’s lightweight, rolls out smoothly, and cuts easily, making it ideal for DIY projects. It provides a nice cushioning effect that adds comfort underfoot.

Many foam products come as 2-in-1 or 3-in-1 combination underlayments with a built-in vapor barrier, simplifying moisture protection. The main trade-off is that foam can compress over time in high-traffic areas. While it offers some sound dampening, it’s not the best for noise reduction in multi-story homes. Still, for many installations, foam offers an excellent balance of affordability and functionality.

Cork: The Natural Sound and Thermal Insulator

If foam is the practical choice, cork is the high-performer. Harvested from cork oak tree bark, this natural material brings superior performance to your floor.

Cork’s main benefit is sound absorption. Its cellular structure naturally dampens impact noise, making it perfect for condos or multi-story homes. It also provides excellent thermal insulation, keeping floors warmer in winter. As a renewable, sustainable resource, cork is an eco-friendly choice with natural antimicrobial properties that resist mold and mildew.

The catch? Cork typically costs more, with prices based on general market data ranging from $0.75 to $2.25 per square foot. These are industry averages and not a quote for services. Most cork underlayment also requires a separate 6-mil polyethylene sheet for a moisture barrier, especially over concrete. For those prioritizing eco-friendliness and sound reduction, cork is worth the investment.

Felt: The Dense and Durable Sound Blocker

Felt underlayment, made from recycled textile fibers, is a quiet champion in the flooring world. Its key feature is density, which creates a thick layer that resists compression and provides superior sound blocking. If noise is a concern, felt delivers serious acoustic performance.

This density also provides a luxurious cushioning effect, giving your floor a solid, premium feel. Felt can help smooth out minor subfloor imperfections and is often made from recycled materials. Based on general market data, felt typically costs between $0.60 and $1.80 per square foot, placing it in the mid-to-premium range. These are industry averages and not a quote for services.

The main caution is that felt can absorb moisture. For installations over concrete or in damp areas, you must use a felt product with an integrated moisture barrier or lay a separate vapor barrier underneath to prevent it from acting like a sponge.

Rubber: The Ultimate in Durability and Performance

When you need the absolute best in performance and durability, rubber underlayment is the answer. Often made from recycled tires, this heavy-duty option is built to last.

Rubber is the most durable underlayment available and won’t compress, even under heavy furniture or in high-traffic commercial spaces. Its sound insulation is exceptional, dampening both impact and airborne noise. Rubber also offers superior moisture resistance, making it an excellent choice for basements and concrete subfloors.

The downsides are cost and weight. Rubber is the most expensive option, with prices based on general market data ranging from $1.00 to over $3.00 per square foot. These are industry averages and not a quote for services. It’s also heavy and dense, making installation more labor-intensive. However, for projects where performance is non-negotiable, rubber underlayment justifies its premium price.

Choosing the Best Underlayment for Engineered Wood Floating Floor: Key Factors

Picking the best underlayment for engineered wood floating floor isn’t a one-size-fits-all decision. The right choice depends on your subfloor type, room location, and performance needs. Think of it like buying shoes—you need the right type for the right situation. Let’s walk through the key factors to guide your choice. For more general information, visit our guide on hardwood floor underlayment options.

Subfloor Type: Concrete vs. Wood

Your subfloor is the foundation, and it dictates your underlayment needs.

For plywood or OSB subfloors, your main concerns are minor surface imperfections and sound transmission. Wood subfloors are generally drier than concrete, but a moisture test is still a wise precaution. Most importantly, ensure your subfloor is flat—within 1/8 inch over a 6-foot span or 3/16 inch over a 10-foot span. Underlayment can smooth out tiny bumps, but it won’t fix major structural issues.

For a concrete slab, moisture is the primary enemy. Concrete is porous and can wick moisture from the ground, which is why a vapor barrier is non-negotiable. This applies to on-grade (ground level) and even upper-floor concrete slabs. The concrete must also be clean, dry, and flat to the same standards as wood subfloors to ensure the stability and longevity of your new floor.

Moisture Control and Vapor Barriers

Moisture will destroy an engineered wood floor faster than anything else. Even though engineered wood is more stable than solid hardwood, it’s still a wood product.

In a basement or any below-grade space, a moisture barrier is absolutely essential. A proper moisture retarder is a 6-mil plastic sheet. Many modern foam and combination underlayments integrate this barrier, simplifying installation. If you choose an underlayment without one, like some cork or felt options, you must lay down a separate 6-mil polyethylene film first.

A critical detail is ensuring sealed seams. Whether using an integrated or separate barrier, butt the seams together and seal them with quality tape. This creates a continuous shield against moisture. For step-by-step guidance, our article on how to install engineered hardwood flooring on concrete walks you through the process.

Sound Reduction and Comfort

A quality underlayment dramatically reduces noise transmission between floors, a key feature for multi-story homes, apartments, or condos with specific noise requirements. Underlayments are rated with Impact Insulation Class (IIC) for impact sounds (footsteps) and Sound Transmission Class (STC) for airborne sounds (voices). Premium underlayments can achieve high ratings. You can find these specifications in the product’s manufacturer guides.

Beyond quiet, underlayment adds a cushioning effect that makes your floor more comfortable to walk on, reducing foot fatigue. This slight give also reduces stress on the flooring joints, helping your floor last longer.

Underlayment Thickness and Budget

Underlayment thickness typically ranges from 2mm-3mm up to 6mm or more. While thicker options often provide better soundproofing, too much cushion can be a problem. Excessive flex puts stress on the floor’s locking mechanisms, potentially leading to gaps over time. Always check your flooring manufacturer’s recommendations for thickness to ensure joint stability. For example, some products are specifically designed at a certain thickness (e.g., 1/8 inch) to create stronger joints.

Regarding budget, based on general market data, underlayment costs typically range from $0.25 to over $3.00 per square foot, depending on the material. These are industry averages and not a quote for services from Romero Hardwood Floors. While it’s tempting to save money on this hidden layer, skimping on underlayment is like buying cheap tires for an expensive car. It protects your investment and prevents costly repairs. For a broader understanding of flooring costs, explore our article on engineered hardwood flooring installation cost.

Installation Essentials: A Step-by-Step Guide

Proper installation is just as crucial as choosing the right material. Even the best underlayment for engineered wood floating floor won’t perform correctly if installed poorly. The good news is that with careful preparation, you can ensure your underlayment provides a solid foundation for your new floor.

- Start with a clean, level subfloor. Your subfloor must be spotless, dry, and flat before you begin. Sweep and vacuum all debris. Correct any significant dips or humps to within 1/8 inch over a 6-foot span or 3/16 inch over a 10-foot span. A level subfloor prevents squeaks and instability.

- Acclimate all materials. Both your engineered wood flooring and underlayment need to adjust to your home’s temperature and humidity for at least 24 to 72 hours before installation. This prevents gapping or buckling later. Maintain a relative humidity between 30% and 50% for best results.

- Roll out the underlayment. Lay the underlayment across the prepared subfloor. If it includes a vapor barrier film, ensure the correct side faces up (usually the imprinted side). We typically run underlayment perpendicular to the direction of the flooring planks, but always check the manufacturer’s instructions.

- Seal every seam. This step is critical. Butt the seams together flush—never overlap the padding itself—and securely tape them with quality duct tape or strapping tape. This creates a continuous moisture barrier. Some products simplify this step with a self-adhesive overlap system.

- Leave an expansion gap. Leave a 1/2 to 3/4-inch gap between the underlayment and the walls. This allows the underlayment and flooring to expand and contract with seasonal changes, preventing buckling.

- Follow manufacturer instructions. This is the most important rule. Always consult the specific installation guides from both your flooring and underlayment manufacturers. Their guidelines are essential for maintaining warranties and ensuring proper performance.

For comprehensive guidance on the entire process, check out our resources on hardwood floor installation and engineered hardwood flooring installation.

Frequently Asked Questions about Underlayment for Floating Floors

We often get asked similar questions about underlayment for engineered wood floating floors. Here are some of the most common inquiries we address:

Can underlayment fix an uneven subfloor?

This is a common misconception. While underlayment can smooth out minor subfloor imperfections, it is not a substitute for proper subfloor preparation. Think of it as a thick blanket—it can hide small bumps but can’t fill a large hole.

If your subfloor is uneven by more than 3/16 inch over a 10-foot radius, you must address it directly by sanding high spots or using a self-leveling compound on low spots. Relying on underlayment to fix major issues can lead to squeaks, flex, and damage to the floor’s locking mechanisms. For significant repairs, it’s best to consult sub-flooring contractors near you.

What is the best underlayment for engineered wood floating floor over concrete?

When installing over concrete, moisture is the primary concern, as concrete slabs can transmit damaging moisture vapor. The best underlayment for engineered wood floating floor over concrete must prioritize moisture protection.

Look for these top features:

- Integrated 6-mil Vapor Barrier: This is non-negotiable. An underlayment with a built-in 6-mil polyethylene film creates a necessary shield against moisture.

- Good Compressive Strength: Choose an underlayment that provides firm support to prevent floor joints from separating. Denser felt, rubber, or specialized foam products are excellent choices.

- Mold and Mildew Resistance: High-quality underlayments often include antimicrobial agents to inhibit mold growth, which can occur on cold concrete surfaces.

Even with the right underlayment, always perform a moisture test (calcium chloride or RH test) on the concrete before installation. If moisture levels are too high, additional mitigation steps may be needed. For more details, see our guide on installing engineered hardwood on concrete.

Do I need underlayment if my engineered flooring has a pre-attached pad?

This is a great question. Many engineered wood products come with a thin pad already attached. Here’s what to consider:

- Manufacturer Warranty: First, check the flooring manufacturer’s guidelines. Some warranties are voided if you add a second underlayment.

- Excessive Flex: Adding another layer of padding can create too much cushion, which puts stress on the floor’s locking system and can lead to gaps or joint failure.

- The Moisture Barrier Exception: The main exception is when installing over concrete. If the pre-attached pad does not include a full 6-mil vapor barrier, you should lay a separate 6-mil polyethylene sheet over the concrete first. This provides adequate moisture protection without adding excessive cushioning.

In most cases, if your flooring has a quality pre-attached pad, an additional underlayment is not needed and may even be harmful. Always verify with the manufacturer. For more on this topic, check out our engineered hardwood flooring page.

Conclusion: Making the Right Choice for a Lasting Floor

Choosing the best underlayment for engineered wood floating floor is about protecting an investment you’ll live with every day. This hidden layer isn’t just padding—it’s working to keep your floors comfortable, quiet, and safe from moisture. The right underlayment means the difference between a solid, luxurious floor and one that sounds hollow or fails prematurely.

We’ve covered the four main types: Foam for budget-friendly protection, Cork for natural soundproofing, Felt for dense sound blocking, and Rubber for ultimate durability. Your choice will depend on your subfloor, location, and budget. However, after more than 15 years in this business, we know that cutting corners on underlayment almost always costs more in the long run.

At Romero Hardwood Floors Inc., we’ve seen how proper underlayment selection and installation protect floors for decades. We’ve also seen the costly results of skipping this crucial step.

Our team serves Revere, MA, and the surrounding areas with expertise gained from countless residential and commercial installations. If you’re ready to build a beautiful floor from the ground up, we’re here to help.

Contact us for your hardwood floor installation needs, or request an estimate to discuss your project.

Like us on Facebook!