Engineered Wood Floor Acclimation: Top 5 Essential Tips

Engineered wood floor acclimation is a crucial step in achieving a flawless and long-lasting floor installation. Acclimation involves adjusting the moisture content of engineered wood floors to match the environment where they’ll be installed. This prevents potential issues like warping, gapping, or cupping after the installation is complete.

Whether you’re a homeowner adding a touch of elegance to your living space or a property manager handling commercial installations, understanding the importance of acclimation can save time and money. Here’s what you need to consider:

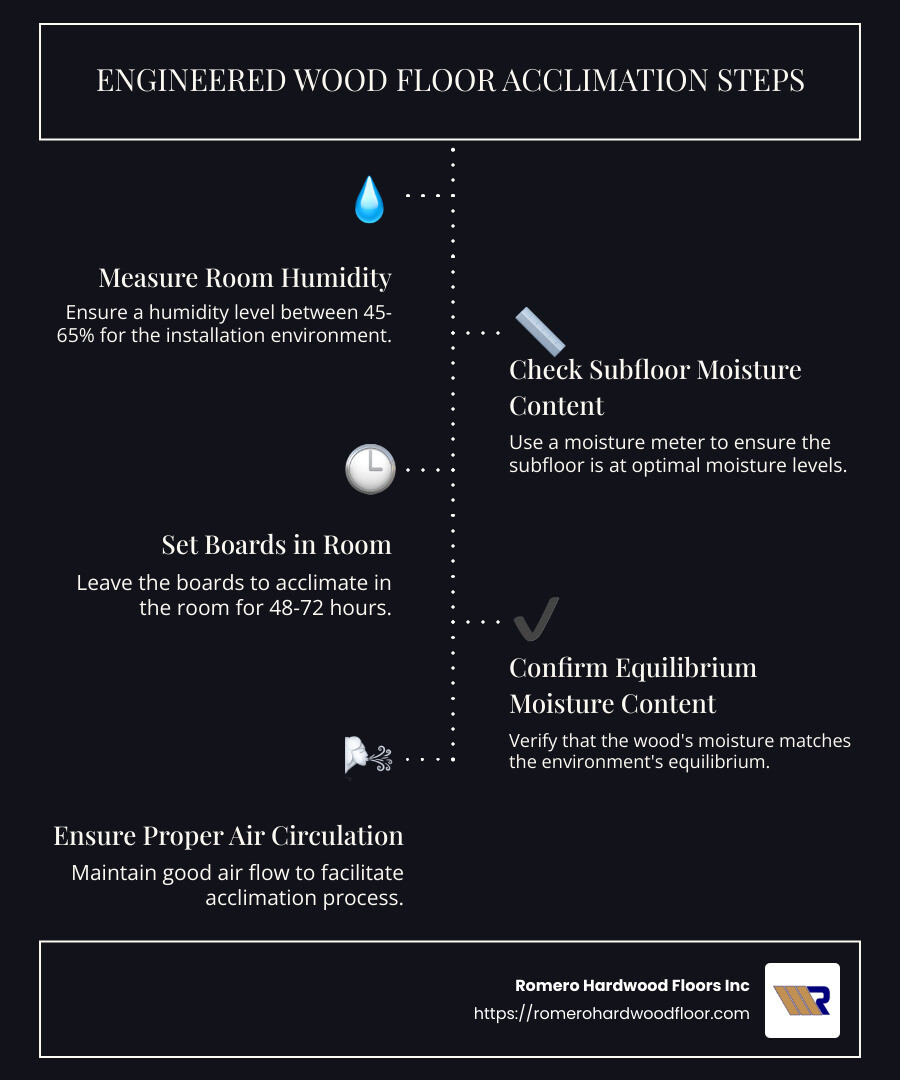

- Environment: Ensure the room is at a stable humidity level between 45-65%.

- Acclimation Time: Generally, acclimate the floorboards for at least 48-72 hours.

- Moisture Testing: Match the wood’s moisture content with your subfloor.

As Francisco Romero from Romero Hardwood Floors, I’ve spent over 15 years perfecting the art of engineered wood floor acclimation across a range of projects. My experience guarantees installations that improve both aesthetic appeal and durability.

Engineered wood floor acclimation basics:

– engineered hardwood floor refinishing

– engineered wood floor adhesive

– engineered wood floor cleaning

Importance of Engineered Wood Floor Acclimation

Engineered wood floor acclimation is not just a step in the installation process; it’s a vital foundation for ensuring your floors last and look great. Let’s break down why this step is so crucial by focusing on three key elements: moisture content, equilibrium, and humidity.

Moisture Content: The Hidden Factor

Moisture content in wood is like the secret ingredient that can make or break your flooring project. When wood absorbs too much moisture, it can swell and warp. If it dries out too much, it can shrink and cause gaps. For engineered wood floors, the goal is to reach a moisture content that matches the environment of the installation site. This prevents problems like cupping or crowning, which are common when moisture levels are off balance.

To avoid these issues, use a moisture meter to measure the moisture content of your wood before installation. This handy tool can save you from potential headaches down the road.

Equilibrium: Finding the Balance

Equilibrium moisture content (EMC) is the point where the wood is neither gaining nor losing moisture. Achieving EMC is like finding the sweet spot where your wood floor feels right at home. Most manufacturers recommend a moisture content range of 6-9% for engineered wood floors.

When wood reaches EMC, it means it’s in harmony with the surrounding environment. This balance is essential for maintaining the structural integrity and appearance of your floors. Without equilibrium, you risk your floors behaving unpredictably as seasons change.

Humidity: The Environmental Influence

Humidity is the environmental factor that plays a significant role in wood floor acclimation. The relative humidity of the room should ideally be between 45-65%. This range helps ensure that the wood floor adjusts properly and stays stable over time.

If the humidity is too high, the wood may absorb excess moisture, leading to swelling. On the flip side, if the humidity is too low, the wood might dry out too much, causing it to contract. Either scenario can lead to costly repairs or replacements.

By controlling humidity levels, you create an environment where your wood floor can achieve and maintain EMC. This is why it’s crucial to ensure that the building’s HVAC systems are running and the space is enclosed before starting the acclimation process.

In summary, understanding and managing moisture content, equilibrium, and humidity are essential steps in the engineered wood floor acclimation process. Getting these factors right ensures your new floors remain beautiful and durable for years to come.

Next up, we’ll dive into the specific steps you can take to acclimate your engineered wood floors effectively.

Steps to Acclimate Engineered Wood Floors

Acclimating engineered wood floors is a crucial step to ensure they last and perform well. Let’s walk through the key steps in the acclimation process, focusing on measuring moisture content and preparing the installation site.

Measure Moisture Content

The first step in the acclimation process is to accurately measure the moisture content of your engineered wood floors. This is where a moisture meter becomes your best friend. By using this tool, you can determine the moisture content of the wood planks as soon as they arrive at the job site.

- Why measure? The goal is to reach an equilibrium moisture content (EMC) where the wood is neither gaining nor losing moisture. For most engineered wood floors, the ideal moisture content is typically between 6-9%.

- How to measure? Check multiple planks from different boxes to get an average reading. If the moisture content matches the EMC specified by the manufacturer, you’re on the right track.

Pro Tip: If the moisture content is significantly off, you might need to return the shipment or allow more time for acclimation. Installing wood with the wrong moisture content can lead to warping or gaps.

Prepare the Installation Site

Preparing the installation site is just as important as measuring the moisture content. The environment where the wood will be installed plays a crucial role in the acclimation process.

- Enclose the Building: Ensure the building is fully enclosed to protect the wood from external weather conditions. Open windows or doors can lead to fluctuating humidity levels, which can disrupt the acclimation process.

- HVAC Systems: Make sure the HVAC systems are running at least five days before the wood arrives. This helps stabilize the temperature and humidity levels within the space. Aim for a temperature between 60° and 80°F and a relative humidity of 45-65%.

- Check Subfloor Conditions: The subfloor should be clean, dry, and level. Any moisture in the subfloor can affect the wood’s moisture content, so it’s important to conduct moisture tests on both wood and concrete subfloors.

By following these steps, you can ensure that your engineered wood floors acclimate properly, reducing the risk of future issues like warping or gaps. With the right preparation, your floors will be ready for a successful installation.

Next, we’ll explore best practices for acclimating engineered wood floors, including acclimation duration and subfloor moisture testing.

Best Practices for Acclimating Engineered Wood Floors

When it comes to engineered wood floor acclimation, following best practices is key to a successful installation. Let’s dig into the recommended acclimation duration and the importance of subfloor moisture testing.

Acclimation Duration

The duration of acclimation is critical. Most manufacturers recommend allowing engineered wood floors to acclimate for 48-72 hours. This timeframe helps ensure the wood reaches the right moisture balance with its environment.

- Why 48-72 hours? This period allows the wood to adjust to the room’s temperature and humidity, minimizing the risk of expansion or contraction after installation.

- Manufacturer Guidelines: Always check the specific recommendations provided by the manufacturer. Some may suggest longer acclimation times based on the wood type or local climate conditions.

Tip: If possible, extend the acclimation period beyond 72 hours for even better results, especially in areas with high humidity fluctuations.

Subfloor Moisture Testing

Testing the moisture content of the subfloor is just as important as acclimating the wood itself. Whether your subfloor is wood or concrete, understanding its moisture condition is crucial.

- Moisture Conditions: Ensure the subfloor’s moisture content is within the acceptable range. For wood subfloors, the moisture content should be no more than 4% different from the engineered wood. For concrete, a moisture barrier might be necessary if levels are too high.

- Testing Tools: Use a reliable moisture meter to check the subfloor conditions. This tool can help you avoid moisture-related problems like warping or mold growth.

Pro Tip: Conduct multiple tests in various areas of the subfloor to get an accurate reading. This ensures consistency and prevents surprises later on.

By adhering to these best practices, you’ll create the ideal conditions for your engineered wood floors, ensuring they look great and last long. Next, we’ll tackle frequently asked questions about engineered wood floor acclimation, addressing common concerns and providing expert insights.

Frequently Asked Questions about Engineered Wood Floor Acclimation

Do engineered wood floors need to acclimate?

Absolutely, engineered wood floors need to acclimate. Even though engineered wood is designed to handle changes in temperature and humidity better than solid wood, it still requires acclimation. This process ensures the flooring adjusts to the environment’s moisture levels, preventing future issues like warping or gaps.

Manufacturers strongly recommend acclimating the floors as per their guidelines. Most suggest a period of 48-72 hours in the installation area. This timeframe helps the wood reach equilibrium with the room’s conditions, minimizing post-installation movement.

How do you acclimatize engineered wood?

Acclimating engineered wood is straightforward but crucial. Follow these steps to ensure your flooring is ready for installation:

- Place the boxes in the room where the flooring will be installed. This allows the wood to adjust to the local temperature and humidity.

- Unbox the planks if space allows, and spread them out. This exposes more surface area to air, promoting even acclimation.

- Ensure proper air circulation. If the room is small, stack the boxes but stagger them to allow airflow between layers.

- Maintain consistent environmental conditions. Keep the room’s humidity between 35-55% and the temperature between 60-80 degrees Fahrenheit.

- Use a moisture meter to check the moisture content of both the flooring and the subfloor. This helps ensure they are within the recommended range before installation.

How long before you can walk on new engineered hardwood floors?

Once your new engineered hardwood floors are installed, patience is key. The waiting period before you can walk on them depends on the installation method and materials used.

- Floating floors: These can often be walked on immediately after installation. However, it’s best to wait at least 24 hours for the planks to settle.

- Glue-down installations: Require a longer waiting period. Allow the glue to set for at least 48 hours before walking on the floor. This ensures a strong bond and prevents shifting.

- Nailed or stapled floors: Similar to floating floors, these can usually be walked on shortly after installation, but waiting a few hours is recommended for optimal results.

Pro Tip: Avoid placing furniture or heavy objects on the new floors for at least 48 hours, regardless of the installation method. This precaution helps prevent indentations and ensures the flooring sets properly.

Conclusion

At Romero Hardwood Floors Inc, we understand that successful flooring installation goes beyond just laying down planks. It starts with proper acclimation, especially for engineered wood floors. This crucial step ensures the flooring performs well over time, maintaining its beauty and functionality.

Why Choose Us?

Our expertise, honed over years of experience since our establishment in 2006, guarantees that your flooring project is in capable hands. We prioritize acclimation because it sets the stage for a flawless installation. By allowing the wood to adjust to your home’s specific conditions, we prevent common issues like warping and gaps, ensuring your floors look and feel perfect.

Commitment to Quality

We are committed to delivering top-notch service, from the initial consultation to the final installation. Our team follows manufacturer guidelines carefully, acclimating your flooring for the recommended 48-72 hours. This attention to detail ensures that your engineered wood floors achieve equilibrium moisture content, crucial for long-term stability.

Enhancing Property Value

With our competitive pricing and guaranteed workmanship, we improve your property’s value, offering you a seamless experience and floors that stand the test of time. Our service areas, including Revere, MA, and surrounding locations, benefit from our dedication to quality and customer satisfaction.

Choosing Romero Hardwood Floors Inc means investing in a partnership that values precision and excellence. We invite you to explore our engineered hardwood flooring services to learn more about how we can transform your space with beautiful, durable flooring. Let us help you achieve the perfect installation, ensuring your floors continue to impress for years to come.