Hardwood Floor Filler: Perfect Repair 2025

Why Proper Hardwood Floor Repair Matters

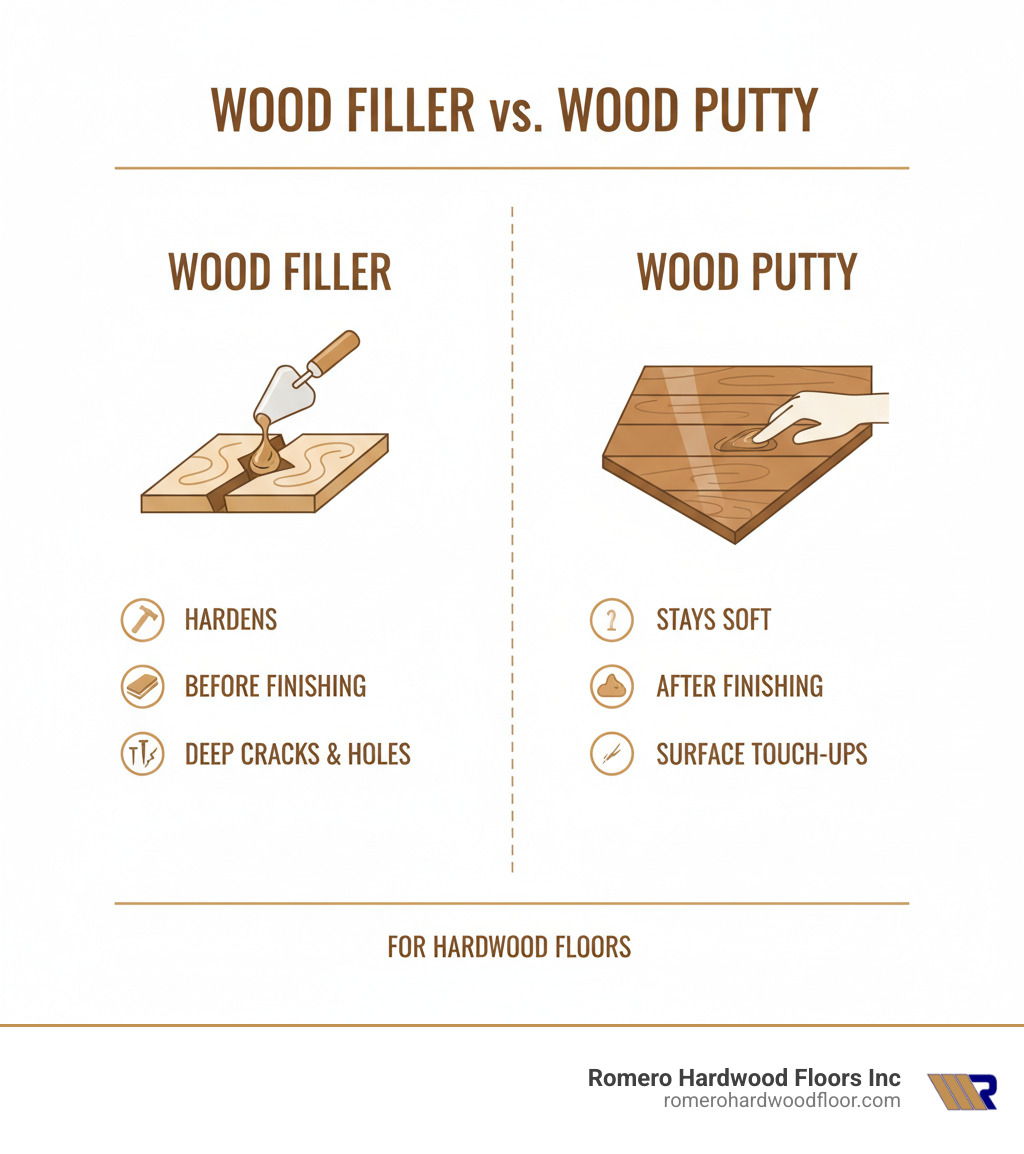

Hardwood Floor Filler is a compound used to fill gaps, cracks, nail holes, and gouges in hardwood floors. The goal is to restore a smooth appearance, but choosing the right product is critical. Here’s a quick overview:

- Wood Filler: Hardens completely, is used before finishing, can be sanded, and is highly durable.

- Wood Putty: Stays soft, is used after finishing, cannot be sanded, and is best for cosmetic touch-ups.

- Best For Small Repairs: Filler is ideal for nail holes, minor scratches, and chips up to ¼ inch.

- Not For Gaps: Seasonal wood movement will cause filler in gaps to crack and crumble.

- Requires Top Coat: Filler must be sealed with a finish like polyurethane for protection.

Over time, all hardwood floors show wear. These blemishes can trap dirt and worsen if ignored. It’s important to know that wood filler is for camouflaging small imperfections, not a cure-all for major floor damage. Using the wrong product or technique can lead to costly mistakes, like filler cracking in seasonal gaps or large patches looking like plastic blobs. Even pros can struggle with color matching and application.

I’m Francisco Romero, owner of Romero Hardwood Floors Inc. With over 15 years of experience repairing floors in Revere, MA, I’ve worked with nearly every Hardwood Floor Filler product available. This guide is based on real-world results, not marketing hype.

Terms related to Hardwood Floor Filler:

Understanding Wood Repair Compounds: Filler vs. Putty

When repairing a hardwood floor, it’s crucial to know that wood filler and wood putty are not the same thing. Using them interchangeably is a common mistake that leads to frustration. Understanding their distinct purposes is the first step to a successful repair.

Wood filler is designed for raw, unfinished wood. It bonds with the wood fibers, penetrates deep into cracks, and hardens into a solid mass. Because it hardens, it’s sandable, allowing you to smooth it flush with the floor for a seamless repair. In my experience, wood filler lasts two to three times longer than wood putty because it becomes an integral part of the floor. It’s the correct choice when you plan to sand and refinish your floors. While it can accept stain, color matching requires careful testing.

Wood putty, on the other hand, is a non-hardening compound for cosmetic touch-ups on already finished floors. Think of it as concealer for minor blemishes. Since it stays soft and flexible, you don’t sand it; you simply apply it, wipe away the excess, and you’re done. This makes it perfect for prefinished floors where you want to preserve the factory finish. However, its softness means it can be worked out of high-traffic areas over time. Unlike filler, wood putty doesn’t accept stain and comes in pre-matched colors.

To put it simply: wood filler is for before finishing, wood putty is for after finishing. Filler is structural, while putty is cosmetic.

| Characteristic | Wood Filler | Wood Putty |

|---|---|---|

| Hardening | Hardens firmly | Stays soft and flexible |

| Best Use | Filling voids in raw, unfinished wood | Cosmetic touch-ups on finished wood |

| Sandable | Yes, must be sanded flush | No, wipe away excess |

| Stainability | Accepts stain (color matching can be tricky) | Does not accept stain well (comes in pre-matched colors) |

| Application Timing | Before finishing/refinishing | After finishing |

| Durability | More durable, bonds tightly, lasts longer | Less durable, can work out of high-traffic areas |

The bottom line is to choose the right product for the job. If you’re refinishing, use wood filler. For a quick touch-up on a finished floor, use wood putty. Using the wrong one can make the problem worse.

For more detailed information on using putty for cosmetic fixes on finished floors, check out our guide on hardwood floor putty repair.

Types of Hardwood Floor Filler and How to Choose

Not all Hardwood Floor Filler products are the same. The right choice depends on the size and depth of the damage, the wood species, and your finishing plans. A tiny nail hole requires a different product than a deep gouge.

When assessing damage, consider its size, depth, wood species, and whether you plan to stain. Dense woods like oak accept filler differently than softwoods like pine, and some fillers absorb stain while others resist it. Seasonal gaps between boards are a special case; most fillers will crack and should be avoided for this purpose.

Water-Based Hardwood Floor Filler

For most DIY repairs, I recommend water-based fillers. They are forgiving, low-odor, and clean up easily with water. These fillers contain wood fibers or other materials in a water-soluble binder, making them eco-friendly with low VOCs. They work best for small cracks, nail holes, and minor surface imperfections. A popular choice is latex wood floor filler, which retains some flexibility. Drying time is typically 30 minutes to 2 hours, but it’s best to wait overnight for a full cure, especially in humid conditions. Their main limitation is that they are less durable than solvent-based options for high-traffic areas.

Solvent-Based Hardwood Floor Filler

For a heavy-duty repair, solvent-based fillers offer strong adhesion and high durability. They use chemical solvents that evaporate to leave an incredibly hard material, making them ideal for larger repairs, deep gouges, and high-traffic areas. The trade-off is higher VOC levels and strong odors, so proper ventilation is essential. Cleanup requires mineral spirits or paint thinner. While messier, the durability is often worth the extra effort for repairs that need to last.

Specialty and DIY Fillers

Sometimes, standard products aren’t enough.

Two-part epoxy systems are the strongest option, creating a waterproof, sandable material perfect for filling large voids or rebuilding damaged wood. Epoxy hardens quickly, so you must work fast.

For the best color match, nothing beats a DIY filler made from sawdust and a binder. Mix fine sawdust from the floor you’re repairing with a clear binder like wood glue or epoxy. This creates a paste with the exact wood fibers of your floor, ensuring a natural blend. Be aware that wood glue can dry with a yellowish tint, so for lighter woods, a clear epoxy binder is better.

My most important advice: always test your chosen filler and stain on a scrap piece of wood or in an inconspicuous area first. A five-minute test can prevent a DIY disaster where the filler color doesn’t match after staining.

The Complete Hardwood Floor Filler Repair Process

Repairing floors with filler is a detailed process that requires patience. When done right, a Hardwood Floor Filler repair can be nearly invisible. The basic tools are a putty knife, sandpaper, a sanding block or orbital sander, a vacuum, and your filler. For more repair strategies, see our guide on hardwood floor repair techniques.

Step 1: Surface Preparation

Proper preparation is the most critical step for a lasting repair. Skipping it is the top reason DIY fills fail.

First, clean the void thoroughly. Use a utility knife to scrape out any loose debris, dirt, or old finish until you reach solid wood. Next, vacuum the area carefully to remove all dust, which can prevent the filler from adhering properly. For raw wood or areas being refinished, lightly sand around the damage with 120-grit sandpaper to create a better grip for the filler. If you’re refinishing an entire floor, apply filler after the initial coarse sanding pass, as this will reveal all the imperfections. Finish with one last vacuum. A clean surface is essential for strong adhesion, a key part of floor sanding and repair.

Step 2: Application and Drying

Technique is key when applying Hardwood Floor Filler. Scoop a small amount onto a putty knife and press it firmly into the void, eliminating air pockets. For deeper gouges, apply the filler in thin layers (no more than 6mm at a time), allowing each to dry. This prevents cracking and shrinkage that can occur with thick applications. Always overfill slightly (about 1/16 inch) to account for shrinkage as the filler dries.

For floors with many small cracks, a technique called trowel-filling can be used. This involves spreading a thin layer of filler across the entire surface before the final sanding passes of a refinishing job.

Now, be patient. Drying time depends on the filler type, depth, humidity, and temperature. While some fillers feel dry in 30 minutes, I recommend waiting at least 6 hours for shallow fills and overnight for deeper ones. Rushing this step is a common mistake.

Step 3: Sanding and Finishing

Once the Hardwood Floor Filler is completely dry, it’s time to sand and finish. Start by sanding the filled area flush with the surrounding floor using a sanding block with 120- to 150-grit sandpaper. Work carefully to avoid creating a depression. Check for smoothness with your hand; it should feel uniform. Vacuum thoroughly to remove all sanding dust.

If staining, test the stain on a scrap piece of wood with the same filler first. Fillers absorb stain differently than wood, so this test helps you predict the final color. After testing, apply stain to match the surrounding area. Wood color varies from board to board, so aim for a local match.

Finally, seal the repair with a top coat like polyurethane. This protective layer is essential for durability and protects the filler from wear and moisture. These finishing steps are crucial for a professional result, as detailed in our guide to finishing hardwood floors.

Common Problems and Expert Solutions

Working with hardwood floor filler can have its challenges. Most mishaps, from cracking filler to poor color matches, are preventable once you know the cause. For more on floor damage, visit our hardwood floor damage repair page.

Why Your Hardwood Floor Filler is Cracking

Cracked filler is a common frustration, usually caused by wood’s natural behavior. Hardwood expands in humid summer months and contracts in dry winter air. If you use a rigid filler in a gap that experiences this movement, the filler can’t flex and will crack and crumble. This is why filler in seasonal gaps often ends up looking like “kitty litter.”

Applying filler too thickly is another cause. A thick layer dries unevenly, creating internal stress that leads to cracks.

The solutions are:

- Use a flexible filler for areas prone to movement. Latex wood floor filler is a good option as it’s designed to move with the wood.

- Apply filler in thin layers (no more than 6mm), letting each dry completely before adding the next.

- Control humidity. Maintaining indoor humidity between 30% and 50% year-round minimizes wood movement and is the best way to prevent hardwood floor shrinkage repair issues.

Achieving a Perfect Color Match

Color matching is one of the trickiest parts of floor repair. Wood varies in tone and grain, and different species accept stain differently. Oak’s open grain absorbs stain readily, while maple’s tight grain can be resistant.

Here are our professional tips:

- Test on scrap wood first. Always experiment with your filler and stain on a spare piece of flooring to see the final result before applying it to your floor.

- Mix custom colors. Many “stainable” fillers don’t match perfectly. We often mix different colored fillers to create custom shades that mimic natural wood variations.

- Use a DIY sawdust filler. For the most authentic match, mix sawdust from your floor with a clear binder like wood glue or epoxy. The filler will contain the exact same wood fibers.

- Match the specific spot. Don’t try to match the average color of the whole floor. Blend the repair with the immediate area, which may be a darker knot or a lighter section of sapwood.

For more on color, see our guide on color refinishing hardwood floors.

When to Repair vs. When to Replace a Board

Hardwood floor filler is for camouflaging small holes and chips, not for fixing structural problems. It works beautifully for cosmetic repairs like nail holes and minor scratches. However, filler cannot provide structural support, hold split boards together, or fix wood rot.

For large gouges, filler is not ideal. Large filled areas shrink, lack natural wood grain, and often look artificial. They can also crack or pull away from the edges over time. As a rule of thumb, for damage larger than a quarter, consider other options.

Board replacement is necessary for large holes, deep structural gouges, severe water damage, or warping. While more involved, it’s the correct, long-term solution. For mid-sized damage, alternatives include fitting a wooden plug or a tapered “Dutchman” shim. Our team can help you decide the best approach for your wood floor repair.

Frequently Asked Questions about Hardwood Floor Filler

Here are answers to the most common questions we get about hardwood floor filler, based on years of real-world experience.

Should I fill the seasonal gaps between my hardwood floorboards?

In most cases, the answer is no, do not fill seasonal gaps with traditional wood filler. Hardwood naturally expands and contracts with humidity changes, causing gaps to appear in winter and close in summer. This is normal. If you fill these gaps with a rigid hardwood floor filler, it will crack and crumble when the wood expands. The result is a messy, crumbled line instead of a clean gap.

The best solution is to control your home’s humidity, keeping it between 30-50% year-round with a humidifier and dehumidifier. This minimizes wood movement and is the proper approach to hardwood floor shrinkage repair. Small cracks within a board should be filled, but for wide seasonal gaps, flexible options like rope caulk or cork strips are better alternatives.

Can I use wood filler on a prefinished floor?

Yes, but you must use the right product. Since you won’t be sanding the floor, a traditional sandable hardwood floor filler is not the right choice. Instead, use a non-hardening wood putty. These products are often wax- or oil-based and come in various colors to match your floor’s finish. Simply press the putty into the nail hole or scratch and wipe the excess off the finished surface immediately. These putties are less durable and best for low-traffic areas, as they can be worked out over time.

How long does wood filler need to dry before sanding?

The answer is: it depends. Drying time for hardwood floor filler is affected by the filler type (water-based vs. solvent-based), the depth of the fill, humidity, and temperature. While a thin layer might be dry to the touch in 30 minutes, rushing the process can ruin the repair.

As a practical guideline, we recommend waiting at least 6 hours for shallow fills and preferably overnight for deeper ones. This ensures the filler is fully cured, not just on the surface. A good rule is to apply filler before a long break or at the end of the day. If you can press your fingernail into the filler and it leaves a mark, it’s not ready. If it’s rock-hard, you can proceed with sanding.

Conclusion

This guide has covered the essentials of using hardwood floor filler. The key takeaway is that wood filler is for cosmetic repairs like nail holes, small cracks, and minor gouges. It is not a solution for structural problems or the seasonal gaps that appear between boards.

Success depends on a few critical steps: proper preparation by cleaning the void thoroughly, patient application in thin layers, and adequate drying time. Always test your filler and stain on scrap wood first to avoid color-matching surprises. These steps are the difference between a durable, invisible repair and one that fails quickly.

For extensive damage, or if you want a flawless professional result without the guesswork, expert help is invaluable. At Romero Hardwood Floors Inc., we have been perfecting these techniques since 2006. We serve homeowners and businesses throughout Revere, MA, and across the North Shore of Massachusetts, including Beverly, Chelsea, Danvers, Gloucester, Lynnfield, Malden, Manchester by the Sea, Marblehead, Medford, Melrose, Nahant, Peabody, Reading, Rockport, Salem, Saugus, Somerville, Stoneham, Swampscott, Wakefield, Winchester, Winthrop, and Woburn.

We pride ourselves on competitive pricing, punctuality, and guaranteed workmanship. Your floors are a major investment, and they deserve professional care.

For professional hardwood floor filler repair, contact us for an estimate today! We’re here to help you maintain the beauty and durability of your hardwood floors.

Like us on Facebook!