Understanding Your Options for Foam Under Hardwood Floor

Foam under hardwood floor is a popular choice for floating installations, offering sound dampening, cushioning, and thermal insulation at a budget-friendly price. However, it’s not suitable for all hardwood types—especially nail-down solid hardwood—and may compress over time, losing effectiveness.

Quick Answer: Should You Use Foam Under Your Hardwood Floor?

| Best For | Avoid For | Key Benefits | Main Drawbacks |

|---|---|---|---|

| Engineered hardwood (floating) | Nail-down solid hardwood | Cost-effective ($0.14-$3.20/sq ft) | Can compress over time |

| Laminate flooring | High-moisture areas without vapor barrier | Easy DIY installation | Less durable than cork or rubber |

| Areas needing basic sound reduction | Commercial high-traffic zones | Lightweight and simple to work with | May trap moisture if not properly sealed |

After investing in beautiful hardwood, the underlayment you choose is a crucial detail that affects how your floors perform, feel, and last. Foam is a common choice because it’s affordable, easy to install, and offers benefits like noise reduction and cushioning. But is it right for your project?

Foam is great for some installations but can cause problems in others. Knowing when to use it (and when to choose an alternative) saves you money and future headaches, ensuring your floors look and feel great for years to come.

I’m Francisco Romero, owner of Romero Hardwood Floors Inc. With over 15 years of experience installing hardwood floors in the Revere, MA area, I’ve seen when foam underlayment is the perfect solution and when it’s not. I’m here to share my expertise to help you choose wisely for your home.

What is Foam Underlayment and Why Use It?

Foam underlayment is a thin, cushioned layer placed between your subfloor and new hardwood. Typically made from lightweight polyethylene (PE) or polypropylene (PP), it comes in rolls for easy installation. There are two main types:

- Closed-cell foam: Its sealed air pockets make it excellent at resisting moisture and providing consistent insulation. This is the preferred choice for areas where dampness is a concern.

- Open-cell foam: This type has a sponge-like structure. While it offers cushioning, it can absorb water and is not recommended for moisture-prone spots.

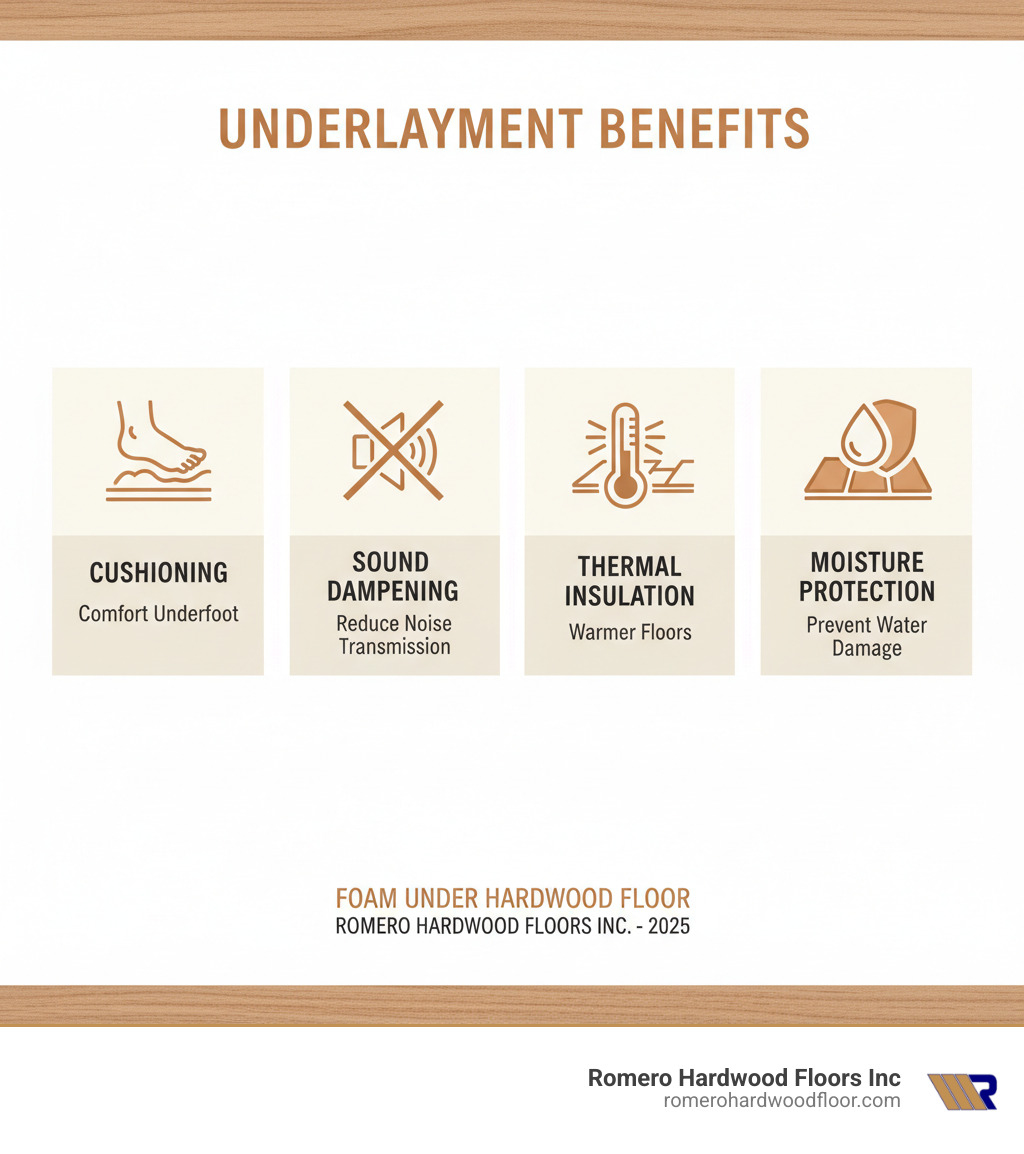

The primary purpose of foam underlayment is to improve your floor’s performance and comfort. It acts as a protective buffer, providing cushioning underfoot and helping to smooth out minor subfloor imperfections for a more even foundation.

The Sound and Temperature Difference

Homeowners immediately notice improved acoustics and temperature after installing foam under hardwood floor.

Foam underlayment excels at impact noise reduction, dampening footfall sounds to create a quieter, more serene home. This is especially beneficial in multi-story homes and apartments to reduce noise transmission between floors.

Beyond acoustics, foam creates a thermal break. In a climate like ours in Massachusetts, this is a significant benefit. A quality foam underlayment makes floors feel noticeably warmer underfoot, especially on cold winter mornings. This extra insulation can also improve your home’s energy efficiency by preventing heat from escaping through the floor. For example, one inch of foam can provide an R-value of 5, adding a solid insulating shield.

Ready to dive deeper into all the ways underlayment can improve your flooring? Check out our guide on underlayment types.

Protection and Longevity

Beyond comfort, foam under hardwood floor plays a vital long-term role in protecting your investment.

Many foam underlayments include an integrated moisture barrier function, which is critical over concrete subfloors or in humid areas like basements. A reliable moisture barrier prevents vapor from the subfloor from damaging your hardwood, which is susceptible to warping, cupping, or buckling from excess moisture.

For floating hardwood installations, foam underlayment is essential for preventing friction. As a natural material, hardwood expands and contracts with temperature and humidity changes. A floating floor isn’t attached to the subfloor, so the foam provides a smooth surface that allows this natural movement without friction. This freedom is key to the floor’s long-term stability and extends its lifespan by reducing stress on the planks.

Curious about all the underlayment possibilities out there? Explore our comprehensive guide on hardwood floor underlayment options.

Evaluating Foam Under Hardwood Floor

When planning a hardwood floor installation, you want a solution that performs well without breaking the bank. Foam under hardwood floor is a popular, budget-friendly option, especially for DIYers. Its versatility with floating floor installations makes it a go-to choice for many homeowners.

However, foam isn’t your only option, and it’s not always the best one. Understanding how it compares to other underlayment materials helps you make an informed decision. Each material has its own strengths. Foam is one of the most affordable choices, typically costing between $0.14 and $3.20 per square foot. For comparison, felt underlayment usually runs from $0.30 to $1.00 per square foot, cork ranges from $0.50 to over $2.00, and rubber can cost anywhere from $1.00 to $4.00 or more per square foot.

Where foam offers basic soundproofing and insulation, materials like cork and rubber provide superior performance. Foam’s durability is moderate, as it can compress over time, while rubber is the most durable option.

Important note: These cost ranges are average costs based on internet data and not actual costs for Romero Hardwood Floors Inc. Pricing can vary significantly based on brand, quality, and your specific supplier.

| Material | Cost (per sq ft) | Soundproofing | Insulation | Durability | Moisture Resistance |

|---|---|---|---|---|---|

| Foam | Low ($0.14 – $3.20) | Basic to Moderate | Basic | Moderate (can compress) | Varies (good with integrated barrier) |

| Felt | Moderate ($0.30 – $1.00) | Good | Good | Good | Basic (often requires separate barrier) |

| Cork | Moderate to High ($0.50 – $2.00+) | Excellent | Excellent | Good | Good (natural antimicrobial) |

| Rubber | High ($1.00 – $4.00+) | Excellent | Good | Excellent | Excellent |

Key Advantages of Foam Underlayment

The primary advantage of foam is its cost-effectiveness. With an average cost per square foot of $0.14 to $3.20, it’s an accessible option for nearly any budget. The price varies based on thickness, brand, and whether it includes a vapor barrier.

Foam is also DIY-friendly. The lightweight rolls are easy to handle and install without special tools. Simply roll it out, cut to size, and tape the seams. This straightforward process is a major benefit for many homeowners.

Finally, foam provides basic sound dampening, reducing the hollow sound of footsteps, and added comfort underfoot, making floors more pleasant to walk on.

Potential Drawbacks and Considerations

Foam underlayment has limitations that are important to understand. The main concern is durability. Foam can compress over time, especially in high-traffic areas or under heavy furniture. This squashing of its air pockets leads to a loss of effectiveness, reducing its cushioning and sound-dampening benefits.

Critically, foam is not for nail-down solid hardwood. I can’t stress this enough. Nailing or stapling solid hardwood requires a firm, stable base. Foam’s soft nature allows too much flex, which can cause fasteners to loosen over time, leading to squeaks and an unstable floor. For traditional solid hardwood, use felt paper or another appropriate firm underlayment.

Lastly, there’s a moisture trapping risk. Some foam products with a plastic backing can trap moisture between the foam and the hardwood, which can lead to mildew and floor damage. This is why the importance of a proper vapor barrier is paramount—it must either allow breathability or effectively channel moisture away.

If you’re planning a floating floor installation, our guide on the best underlayment for engineered wood floating floor offers more detailed advice.

Choosing the Right Foam for Your Hardwood Project

Choosing the right foam under hardwood floor requires careful consideration of your subfloor, hardwood type, room location, and budget. These factors are key to finding the perfect fit for your project, whether you’re in Peabody or Salem, MA.

Selecting by Hardwood Type

Your choice of hardwood flooring is the most important factor when considering foam underlayment.

Foam under hardwood floor is an excellent match for engineered hardwood, particularly in a floating installation. Engineered planks are built for stability and handle moisture changes well, making them ideal for the cushioning and moisture protection foam provides. Since a floating floor isn’t attached, the foam allows the planks to expand and contract naturally without friction.

However, foam is generally not for nail-down solid hardwood. Solid hardwood is nailed or stapled into a wood subfloor. A soft layer like foam underneath creates too much movement, which can loosen fasteners over time and lead to squeaks and instability. For solid hardwood, a firmer base like felt paper is required.

Always check the manufacturer recommendations for both your hardwood and underlayment. Using the wrong product can void your flooring warranty, so this step is crucial for protecting your investment.

If you’re leaning towards engineered hardwood, our engineered hardwood installation guide has more helpful tips.

Understanding Thickness, Density, and Moisture Barriers

Once you’ve confirmed foam is right for your project, consider its specific features.

Thickness: With foam underlayment, thicker isn’t always better. Most products are 2mm to 3mm thick (about 1/12th to 1/8th of an inch). Foam that is too thick or soft can create excessive bounce, stressing the locking mechanisms of floating floor planks. The goal is to find a balance between stability and comfort.

Density and Compression Resistance: Denser foam holds its shape better and resists flattening over time. Higher density means it will maintain its cushioning and sound-dampening properties longer, which is especially important for high-traffic areas in homes across Lynnfield or Stoneham, MA.

Many modern foam options are integrated moisture barriers (2-in-1 products), featuring a thin plastic film on one side. This saves time during installation by combining two steps into one.

Finally, knowing when a moisture barrier is essential is non-negotiable. You absolutely need one in these situations:

- When installing over a concrete subfloor.

- In a basement or any below-grade area.

- In a bathroom or kitchen.

- If a moisture test of your subfloor indicates rising vapor.

- Over a crawl space, especially if it’s damp or unconditioned.

How to Install Foam Underlayment

Installing foam under hardwood floor is a straightforward DIY project. However, careful preparation is key to a successful, long-lasting result. Before you start, gather your tools: a utility knife, measuring tape, marking pen, and manufacturer-recommended sealing tape. For subfloor prep, you may need a broom/vacuum, a level, and repair tools like a hammer or self-leveling compound. For safety, always wear safety glasses and consider knee pads for comfort.

Step 1: Subfloor Preparation

Proper subfloor preparation is the most critical step for a durable hardwood floor. A solid foundation is essential.

First, clear and clean the area. Remove old flooring and baseboards, then thoroughly sweep or vacuum all dust and debris. Even a small pebble can create a bump under your new floor.

Next, check for levelness using a long straightedge. The surface should not vary more than 0.18 inches over a 10-foot radius. Sand down high spots and use a patching or self-leveling compound for low spots, allowing it to dry completely. Repair any imperfections by securing loose nails or screws and fixing damaged subfloor sections.

Finally, ensure the subfloor is dry. Moisture is the enemy of hardwood. A wood subfloor’s moisture content should not exceed 14%. For concrete, always perform a moisture test. Before installation, acclimate your materials by letting the foam and hardwood planks rest in the room for at least 24-48 hours to adjust to the environment. Learn more in our engineered wood floor acclimation guide.

Step 2: Laying and Taping the Foam

With a prepped subfloor, you can now lay the foam under hardwood floor.

Roll out the first row of foam along a wall. Butt the edges of subsequent rows tightly together—do not overlap them, as this creates an uneven surface. Tape the seams securely with the recommended tape to hold the pieces in place and maintain the moisture barrier’s integrity. When you encounter obstacles like pipes, carefully cut the foam to fit around them.

In most cases, the foam lays loose on the subfloor. However, some installations may require approved adhesives to secure it. Always check the manufacturer’s instructions. For example, some installations may specify a particular type of adhesive. You can typically find technical data sheets for these products on the adhesive manufacturer’s website.

Special Considerations for Concrete and Crawl Spaces

When installing over concrete or a crawl space, extra precautions are necessary.

For concrete subfloors, a vapor barrier is paramount. Concrete wicks moisture from the ground, so always choose a foam underlayment with an integrated moisture barrier. If your foam doesn’t have one, you must first lay a separate 6-mil polyethylene sheet. For more guidance, see our articles on installing hardwood on a concrete slab and floating wood floors over concrete.

Rooms over cold crawl spaces can make floors chilly. While a good closed-cell foam under hardwood floor helps, a better solution is to address the crawl space itself. Consider sealing the crawl space (encapsulation) and insulating from below. This provides a much greater impact on your floor’s warmth and your home’s comfort.

Frequently Asked Questions about Foam Underlayment

Is foam underlayment necessary for engineered hardwood?

While not always mandatory, we highly recommend foam underlayment for engineered hardwood. The benefits are significant: sound reduction, added comfort underfoot, and allowing the floor to expand and contract properly without friction against the subfloor. This movement is essential for the floor’s long-term health.

Crucially, many engineered hardwood manufacturers require a specific type of underlayment to maintain the warranty. Skipping this step to save a few dollars could void your warranty when you need it most. Always check the flooring manufacturer’s guidelines.

Can you put foam underlayment under solid hardwood floors?

Generally, no. We do not recommend using foam underlayment with traditional nail-down solid hardwood floors. Solid hardwood needs to be fastened securely to a firm subfloor. Foam is soft and compressible, which creates too much flex and movement under the planks. Over time, this movement can cause the nails or staples to loosen, resulting in squeaks and an unstable floor.

Foam is designed for floating floor installations like engineered hardwood or laminate. For traditional solid hardwood, use a firm underlayment like asphalt-laminated Kraft paper or felt paper to ensure a stable installation.

Does foam underlayment provide a sufficient moisture barrier on concrete?

It depends on the product. Only foam underlayments with an integrated, high-quality vapor barrier—typically a 6-mil polyethylene film—will adequately protect hardwood from moisture rising through concrete. Basic foam without this feature will not prevent moisture damage like warping, cupping, or mold.

For below-grade installations (like basements) or concrete slabs with known moisture issues, you may need additional moisture mitigation steps. This could involve laying a separate vapor barrier or applying a moisture-blocking primer to the concrete before installing the underlayment.

Never assume concrete is dry just because it looks that way. It’s porous and can wick moisture from the ground. Always perform a concrete moisture test before installation. This small step can save you from costly repairs down the road.

Conclusion

So, is foam under hardwood floor the right choice for you? The answer is: it depends on your project.

Foam underlayment is affordable, easy to install, and offers benefits like sound dampening, thermal insulation, and underfoot comfort. It’s often an excellent choice for floating engineered hardwood, especially products with an integrated vapor barrier.

However, foam is not a universal solution. It’s unsuitable for nail-down solid hardwood and can compress over time in high-traffic areas. The key is to match the underlayment to your specific hardwood type, subfloor, and room location.

At Romero Hardwood Floors Inc., we’ve been installing hardwood floors throughout the Revere, Beverly, Chelsea, Danvers, East Boston, Gloucester, Lynnfield, Malden, Manchester by the Sea, Marblehead, Medford, Melrose, Nahant, Peabody, Reading, Rockport, Salem, Saugus, Somerville, Stoneham, Swampscott, Wakefield, Winchester, Winthrop, and Woburn, MA areas since 2006. We know that every home is unique.

We believe your floors should be built on the right foundation. When you get the details right, your hardwood floors will reward you with lasting beauty and performance. If you’re planning a project and want expert guidance on choosing the best underlayment, our experienced team is here to help.

Explore all hardwood floor underlayment options to find the ideal solution for your next project, or reach out to us directly for personalized advice custom to your home.