Best way to strip hardwood floors: Ultimate Easy 2025

Before You Begin: Essential Preparation and Safety

The best way to strip hardwood floors depends on your floor’s condition and your goals. The two main methods are chemical stripping and sanding. Choosing the right one is crucial for success.

- Chemical Stripping is best for delicate floors, such as engineered hardwood or those previously refinished many times. It’s also ideal for preserving original texture and safely removing old paint.

- Sanding is best for solid hardwood floors with deep scratches or significant discoloration. It creates a perfectly smooth surface for a new finish but requires skill to avoid uneven results.

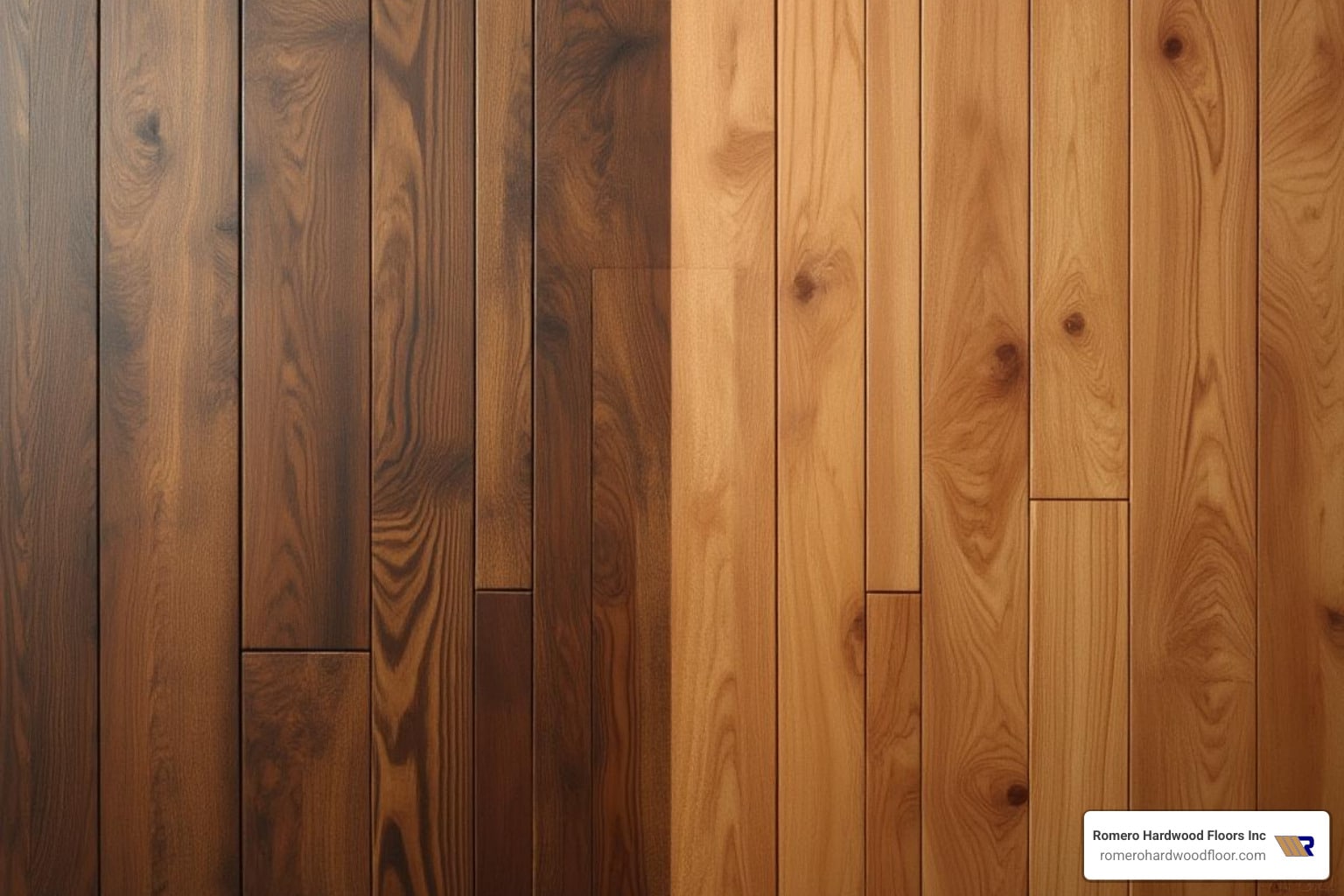

Stripping worn-out hardwood floors can restore their natural beauty and significantly boost your home’s value. I’m Francisco Romero, owner of Romero Hardwood Floors Inc. With over 15 years of experience in Revere, MA, my team and I have mastered this process and are here to help you achieve beautiful, long-lasting results.

Best way to strip hardwood floors glossary:

Before starting, proper preparation and safety are non-negotiable. First, assess your floor’s condition—note any deep scratches, previous refinishing, and the floor’s age. Then, prepare the room by clearing all furniture, sealing vents and doorways with plastic, securing loose floorboards, and hammering down any protruding nails. A final sweep and vacuum will remove loose debris.

Identifying Your Floor’s Finish

Knowing your floor’s finish helps you choose the right method. A simple water droplet test can tell you if the floor needs refinishing: if water soaks in, it does; if it beads up, it may only need cleaning. To distinguish between wax and polyurethane finishes, or to determine if the wood is stained, it’s best to test a small, hidden area.

Critical Safety Precautions

Always prioritize safety when working with chemicals or heavy machinery.

- Ventilation: Ensure the room is well-ventilated by opening windows and using fans. Avoid pointing fans directly at the floor during chemical stripping, as this can dry the stripper too quickly.

- Protective Gear: Wear rubber gloves, safety goggles, long sleeves, and a respirator mask to protect against chemical fumes or fine dust from sanding.

- Chemical Handling: Follow the manufacturer’s instructions for all chemical strippers. Keep water nearby to flush skin or eyes in case of contact.

- Lead Paint Safety: If your home was built before 1980, assume the paint contains lead. Use lead-safe work practices to minimize dust. For more guidance, consult the Lead paint safety information from the EPA.

For more information, see our guide on refinishing original hardwood floors.

Choosing Your Method: Chemical Stripping vs. Sanding

Deciding between chemical stripping and sanding is a critical step. The best way to strip hardwood floors depends on your floor’s type, its condition, and your desired outcome. Each method has distinct advantages.

When to Choose Chemical Stripping

Chemical stripping is a gentle but powerful method that removes old finish without harming the wood itself. It is the preferred choice in several situations:

- Delicate or Thin Floors: For engineered hardwood with a thin veneer or solid wood that has been sanded multiple times, chemical stripping is ideal. It preserves the remaining wood, extending the floor’s life.

- Historic or Detailed Floors: To protect intricate patterns, inlays, or an aged patina, chemical stripping carefully removes the finish without erasing these unique characteristics.

- Painted Floors: Chemical stripping is the safest method for floors painted before 1980, which may contain lead. It dissolves the paint with minimal hazardous dust, unlike sanding. Proper neutralization and cleaning are required afterward.

This method produces less dust than sanding but requires careful chemical handling and good ventilation.

When to Choose Sanding

Sanding is the classic, more aggressive approach for floors that need a complete reset.

- Solid Hardwood: Thick, solid hardwood floors that have not been refinished many times can easily withstand sanding, providing a fresh surface.

- Deep Imperfections: Sanding is the most effective way to remove deep scratches, water stains, and significant discoloration by physically removing the damaged top layer of wood.

- A Perfectly Smooth Finish: If you want a flawless, uniform surface for a new stain or sealer, sanding provides the ideal canvas.

Sanding creates a lot of dust and requires skill to avoid damaging the floor with uneven passes or gouges. For this reason, professional execution is highly recommended to ensure a beautiful result. You can learn more about our approach to professional floor sanding.

The choice between these methods involves balancing your floor’s needs with your goals. We can help you make the right decision.

How-To Guide: The Best Way to Strip Hardwood Floors with Chemicals

Chemical stripping is a precise method ideal for preserving wood’s natural character or for floors too delicate for sanding. It involves gently dissolving the old finish rather than grinding it away.

Before starting, ensure the room is well-ventilated and you are wearing rubber gloves, goggles, and a respirator mask. Work in small, manageable sections (e.g., 3×3 feet) to prevent the stripper from drying out prematurely. This ensures the best way to strip hardwood floors with consistent results.

Tools and Supplies for Chemical Stripping

Gathering your supplies first will make the project go smoothly. You will need:

- Chemical stripper (a product suitable for wood finishes)

- Plastic scraper and putty knife

- Chip brush for application

- Mineral spirits for neutralizing and cleaning

- Rags and paper towels

- Protective gear (gloves, goggles, respirator, long sleeves)

- Buckets

- Fine-grade steel wool for tough spots

- Disposable container for old finish

Step-by-Step Chemical Stripping Process

Follow these steps for a successful chemical strip:

- Prepare Workspace: Clear the room of furniture, cover nearby surfaces, and ensure the floor is smooth by securing loose boards and nails.

- Apply the Stripper: Pour the chemical onto a small section and use a chip brush to spread a thick, even coat over the old finish.

- Wait for it to Work: Let the stripper sit for the time recommended by the manufacturer (typically 15-30 minutes, but sometimes longer). The old finish will begin to bubble and soften.

- Scrape with the Grain: Use a plastic scraper to gently push away the softened finish. Always scrape in the direction of the wood grain to avoid scratching the hardwood. Collect the residue in a disposable container.

- Use Steel Wool for Tough Spots: For stubborn areas or finish in the wood grain, gently scrub with fine-grade steel wool, moving with the grain.

- Clean with Mineral Spirits: Wipe up excess residue with paper towels. Then, use fresh rags soaked in mineral spirits to thoroughly clean the stripped area. Continue wiping with clean rags until no more residue comes up. This step is crucial to ensure the new finish will adhere properly.

- Repeat and Dry: Continue this process section by section across the entire floor. Once finished, allow the floor to dry completely, which may take up to 24 hours. A fully dry surface is essential before applying a new finish.

How-To Guide: Removing Finish by Sanding

Sanding is a powerful method for floors with deep scratches, stains, or when you want to completely change the wood’s color. The process involves a careful grit progression from coarse to fine sandpaper and requires effective dust containment. Because it’s easy to create an uneven surface, we often recommend professional help to achieve a flawless finish and ensure the best way to strip hardwood floors for your home.

Always sand with the wood grain to prevent scratches. Most solid hardwood floors are thick enough to be sanded and refinished up to 10 times over their lifespan.

Tools and Supplies for Sanding

For a successful sanding project, you will need specialized equipment:

- Drum sander for main floor areas

- Edger sander for walls and corners

- Sandpaper in multiple grits (coarse 36-40, medium 60, fine 100)

- Shop vacuum and tack cloths for dust removal

- Safety gear (dust mask/respirator, goggles, ear protection)

- Hand scraper for tight spots

Step-by-Step Sanding Process

Follow these steps for professional-looking results:

- Prepare the Room: Clear all furniture, seal doorways and vents with plastic sheeting to contain dust, and fix any protruding nails or loose floorboards.

- Rough Sanding (Coarse Grit): Using a drum sander with 36- to 40-grit sandpaper, sand the floor moving with the wood grain. Keep the sander in constant motion to avoid creating dips.

- Edge and Corner Sanding: Use an edger sander with the same coarse grit to sand areas the drum sander can’t reach. Use a hand scraper for very tight corners.

- Intermediate Sanding (Medium Grit): Switch to 60-grit sandpaper on both sanders and go over the entire floor again to smooth out marks from the coarse grit.

- Final Sanding (Fine Grit): Use 100-grit sandpaper for the final pass. This will create a very smooth surface ready for staining or finishing.

- Thorough Dust Removal: After the final sanding, it is critical to remove all dust. Sweep, then vacuum thoroughly with a shop vac. Finish by wiping the entire floor with tack cloths. Any remaining dust will ruin the new finish.

For more details, check out our comprehensive guide on how to sand floors.

After the Strip: Next Steps and Troubleshooting

Once your floor is stripped, you have a blank canvas. This stage is critical for ensuring your revitalized floor looks great and lasts for years. Inspect the bare wood for any rough spots, missed finish, or sticky residue. This is also the time to fill minor nail holes or dents with wood filler.

Preparing for a New Finish

With the floor bare and clean, it’s time to prepare it for its new protective layers.

- Final Light Sanding: A final pass with a floor buffer and a very fine-grit screening pad (called “screening”) will smooth out any minor imperfections and prepare the wood to accept the new finish.

- Thorough Dust Removal: After sanding, sweep, vacuum, and use tack cloths to remove every speck of dust. Dust is the enemy of a smooth finish.

- Condition, Stain, and Seal: To prevent a blotchy appearance, apply a wood conditioner before staining. Then, choose your stain or sealer. A stain can change the wood’s color, while a clear sealer like polyurethane, varnish, or oil will protect the wood and improve its natural beauty.

- Apply the Finish: Apply your chosen product smoothly and evenly, working with the grain from the corner farthest from the door. Allow each coat to dry completely, and lightly sand with ultra-fine grit sandpaper between coats for the best results.

Ready to explore the possibilities? Check out our guide to floor restoration options.

Handling Common Problems

Even with care, issues can arise. Here’s how to handle them:

- Stubborn finish spots: Reapply chemical stripper and let it sit longer, or use steel wool. If sanding, carefully go over the spot again with a slightly coarser grit.

- Chemical residue: If mineral spirits don’t remove all residue, use a specialized residue remover. Wipe with clean rags until they come up clean to ensure the new finish adheres properly.

- “Gummy” sandpaper: When sanding old wax or thick finishes, the paper can clog. Use “open cut” sandpaper designed to resist gumming, or perform a chemical pre-strip.

- Accidental gouges: Small gouges can be sanded out. Deeper ones may require wood filler, though matching the grain can be difficult.

- Water damage marks: Light stains can be sanded, but severe water damage may require bleaching the wood or replacing boards. This is where professional expertise from a team like Romero Hardwood Floors Inc. is invaluable.

Frequently Asked Questions about Stripping Hardwood Floors

Here are answers to some common questions about stripping hardwood floors.

How many times can a hardwood floor be stripped and refinished?

The answer depends on your floor type.

- Solid hardwood floors are thick and can typically be sanded and refinished up to 10 times, allowing them to last for generations.

- Engineered wood floors have a much thinner top layer of real wood. They can usually only handle one or two light sandings. For these floors, chemical stripping is often the best way to strip hardwood floors to avoid damaging the veneer.

What’s the best way to strip hardwood floors that are painted?

For painted floors, especially in homes built before 1980, safety is the top priority due to the risk of lead paint. The best way to strip hardwood floors in this case is chemical stripping. This method dissolves the paint and creates far less hazardous dust than sanding, which can release toxic lead particles into the air.

Aggressive sanding of potentially lead-based paint should be avoided. Always test for lead before starting, and consult the EPA for safety guidelines: Lead paint safety information from the EPA.

Can I strip just one section of my hardwood floor?

Stripping and refinishing just one section is not recommended. It is extremely difficult to match the color, sheen, and texture of the new section to the surrounding aged floor. This often results in a noticeable “patch” that detracts from the floor’s appearance.

For a seamless, uniform look, it is always best to strip and refinish the entire room. For minor spot repairs, professional advice is recommended to achieve the best possible blend.

Conclusion: Achieving Your Dream Floors

We’ve covered the key methods, from preparation to finishing, to help you find the best way to strip hardwood floors. This project takes patience and attention to detail, but the reward is a beautifully revitalized floor that adds significant value and character to your home.

While a DIY approach is possible, complex situations like lead paint or the desire for a flawless, professional result often call for expert help. Knowing when to hire a professional is key to a successful outcome without the stress and hassle.

That’s where Romero Hardwood Floors Inc. can help. Since 2006, we have provided expert flooring solutions from our base in Revere, MA. We proudly serve Beverly, Chelsea, Danvers, East Boston, Gloucester, Lynnfield, Malden, Manchester by the Sea, Marblehead, Medford, Melrose, Nahant, Peabody, Reading, Rockport, Salem, Saugus, Somerville, Stoneham, Swampscott, Wakefield, Winchester, Winthrop, and Woburn. Our commitment is to competitive pricing, punctuality, and guaranteed workmanship.

Ready to bring your hardwood floors back to life? Let us help you achieve the dream floors you’ve been imagining.

Get an estimate for your hardwood floor refinishing project with Romero Hardwood Floors Inc. today!