Engineered Wood Floor Adhesive: 3 Pro Picks 2025

Why Choosing the Right Adhesive Matters for Your Floor

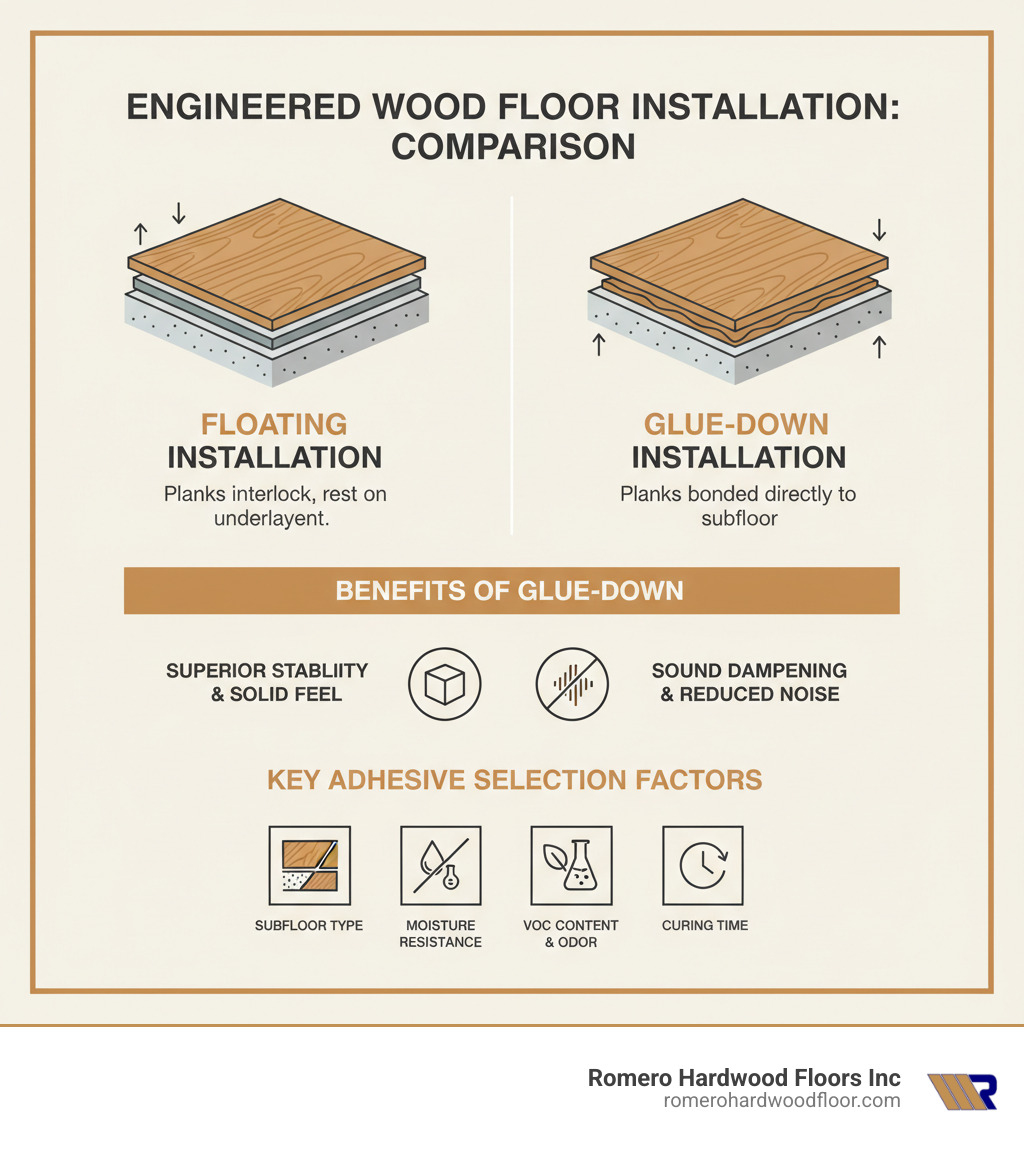

Engineered Wood Floor Adhesive is the critical component bonding your wood planks to the subfloor, ensuring the stability and longevity of your flooring. With the global engineered wood flooring market valued at $115.2 billion in 2023, glue-down installation remains the preferred method for its superior stability and sound dampening. Unlike floating floors, a glued-down floor feels solid, reduces noise, and creates a permanent bond.

Choosing the right adhesive is as important as the flooring itself. The wrong choice can lead to cupping, buckling, hollow spots, and adhesive failure, potentially voiding your warranty and leading to costly repairs. The right adhesive depends on your subfloor, moisture levels, and environmental factors.

Main Adhesive Types:

- Polyurethane: Excellent moisture resistance and flexibility.

- Acrylic Latex: Water-based, low-VOC, and easy to clean.

- Silane-Modified Polymer (SMP): A hybrid with the best of both.

Key Selection Factors:

- Subfloor type (concrete, plywood, etc.)

- Moisture levels

- Environmental features (VOCs, odor)

- Application specs (open/working time)

As Francisco Romero, owner of Romero Hardwood Floors Inc., I’ve seen how crucial the right adhesive is for a flawless, long-lasting result. This guide will walk you through making an informed decision for your project.

Understanding the Main Adhesive Types

Choosing the right Engineered Wood Floor Adhesive is about finding the best match for your specific project. The chemical composition of an adhesive determines its bond strength, flexibility, and performance in your environment. Let’s break down the three main types.

| Adhesive Type | Bond Strength | Flexibility | Moisture Resistance | VOC Content | Cleanup | Typical Use Cases |

|---|---|---|---|---|---|---|

| Polyurethane | High | High | Excellent | Moderate | Mineral Spirits | High-traffic areas, concrete subfloors, areas with temperature/humidity fluctuations |

| Acrylic Latex | Medium-High | Medium | Good | Low | Water | Residential, light commercial, DIY, plywood subfloors |

| Silane-Modified Polymer | High | High | Excellent | Very Low | Mineral Spirits | Wide planks, challenging substrates, radiant heat, moisture-sensitive areas |

Polyurethane Adhesives

Known as the professional’s choice, polyurethane adhesives offer exceptional bond strength and high flexibility. This combination allows your floor to remain firmly attached while moving naturally with environmental changes. Their excellent moisture resistance makes them ideal for concrete slabs or humid areas like basements and kitchens. Some formulations even act as a moisture barrier, saving an installation step.

Available in solvent-based and 100% solids urethane options, these adhesives are well-suited for high-traffic areas. When deciding between engineered vs solid hardwood, polyurethane works exceptionally well with engineered products. The main downside is that cleanup requires mineral spirits.

Acrylic Latex Adhesives

For DIY enthusiasts, acrylic latex adhesives are a user-friendly, water-based option. Their primary advantages are low VOC content and low odor, improving indoor air quality during installation. Cleanup is simple—just use water while the adhesive is still wet. These fast-drying adhesives allow for a quicker installation process.

Many acrylic latex adhesives offer low odor, antimicrobial protection, and good bond strength for residential and light commercial use, especially over plywood. Their moisture resistance is generally lower than polyurethane, so they are best suited for most above-grade installations.

Silane-Modified Polymer (SMP) Adhesives

SMP adhesives represent the latest in Engineered Wood Floor Adhesive technology. This hybrid technology combines the best of polyurethane and silicone, creating a highly elastic bond that handles significant wood movement. This makes them ideal for wide planks and challenging substrates.

SMP adhesives offer excellent moisture protection, often eliminating the need for a separate moisture barrier. They are also solvent-free with very low VOC content, making them an environmentally friendly choice. Their versatility has made them dominant in many markets. They are well-suited for installations over radiant heat or in moisture-sensitive areas. While they are typically priced at a premium, their performance in challenging conditions is often worth the cost.

Key Factors for Choosing Your Engineered Wood Floor Adhesive

Selecting the right Engineered Wood Floor Adhesive requires careful consideration of your project’s unique needs. A proper evaluation of your subfloor, moisture conditions, and desired performance features is essential for a floor that will last for decades.

Subfloor Compatibility and Condition

The subfloor is your floor’s foundation, and its type and condition dictate the best adhesive choice.

- Concrete subfloors are common but can trap moisture. Polyurethane or SMP adhesives are recommended for their strong bond and ability to handle moisture vapor. The concrete must be level to prevent hollow spots and squeaks. Proper preparation is key when you installing engineered hardwood on concrete or any hardwood floor on a slab.

- Plywood subfloors are more porous, allowing for a strong grip. Acrylic latex adhesives often work well here. The plywood must be clean, dry, and structurally sound before installation.

- Existing flooring like tile or vinyl requires an adhesive formulated for multi-surface applications. Always verify compatibility with both the old and new flooring.

Moisture Resistance and Vapor Barriers

Moisture is a primary enemy of wood flooring. Even stable engineered wood can cup or buckle if moisture is not controlled, especially in below-grade installations. The right Engineered Wood Floor Adhesive is your first line of defense.

Many modern polyurethane and SMP adhesives are 2-in-1 products, acting as both an adhesive and a moisture barrier. This simplifies installation and provides comprehensive protection. We always perform moisture testing on concrete subfloors to ensure the slab is within acceptable limits. This is especially important for the best engineered wood flooring for kitchen installations, where humidity and spills are common.

What to Look for in an Engineered Wood Floor Adhesive

Premium adhesives offer features that improve comfort, safety, and performance:

- Low-VOC content: Important for indoor air quality, many adhesives meet strict LEED standards for environmental safety.

- Odor level: Low-odor formulas make the installation process more pleasant and become virtually odorless once cured.

- Antimicrobial properties: Some adhesives inhibit the growth of mold and mildew, adding a layer of protection.

- Sound dampening: Elastic adhesives (SMP and polyurethane) absorb impact and reduce footfall noise, a key one of the engineered hardwood benefits.

- Crack bridging capabilities: Premium adhesives can span minor subfloor cracks (up to 1/8 inch), preventing them from transferring to the finished floor.

Best Practices for Application and Curing

The best Engineered Wood Floor Adhesive in the world won’t perform optimally without proper application. Our years of experience in engineered hardwood flooring installation have taught us that meticulous application and adherence to curing guidelines are just as important as the adhesive itself.

Trowel Selection and Spreading

Your trowel is a critical tool for applying the correct amount of adhesive. The notch size and shape determine the bond strength and coverage rate. Manufacturers typically recommend specific square-notch trowels for engineered wood. Using the wrong trowel can lead to a weak bond or wasted adhesive, affecting your overall cost to install glue down engineered flooring.

Hold the trowel at a consistent 45-degree angle and spread the adhesive in manageable sections. The goal is to achieve 80-100% coverage on the back of each plank to prevent hollow spots, which can cause squeaks and movement.

Open Time, Working Time, and Curing

Understanding adhesive timeframes is crucial for a smooth installation.

- Open time is how long the adhesive can be exposed to air before you must place the flooring into it.

- Working time is the total period you have to adjust planks after application.

These times vary by product, so plan your work in sections that align with the manufacturer’s guidelines. Don’t spread more adhesive than you can cover within the open time.

After the planks are laid, the importance of full curing cannot be overstated. Most adhesives require 24 to 48 hours to reach full bond strength. During this period, you must allow the adhesive to cure properly by keeping all foot traffic off the floor. Rushing this step can compromise the entire installation. Proper engineered wood floor acclimation before installation is also essential to minimize movement.

Ventilation and Safety

Proper ventilation is a critical safety measure that also aids in curing. Adequate airflow helps dissipate fumes from VOCs and allows moisture and solvents to evaporate, which is especially important for water-based adhesives. Opening windows or using fans (without blowing debris onto the adhesive) improves indoor air quality and ensures the adhesive cures correctly.

Always follow the manufacturer’s safety precautions, including wearing personal protective equipment (PPE) like gloves and eye protection. This protects your health and ensures a safe work environment.

Beyond the Bond: Advanced Features & Common Pitfalls

The Engineered Wood Floor Adhesive you choose does more than just bond your floor; it improves its performance and protects your investment. Understanding its advanced features and the pitfalls of a poor choice is key to ensuring your engineered hardwood flooring installation cost yields a floor that lasts.

The Role of Adhesives in Sound and Crack Bridging

Premium elastic adhesives, like SMP and some polyurethanes, offer significant acoustic benefits. They absorb impact sound, dampening vibrations and reducing the hollow, echoing noise of footfalls. This is especially valuable in multi-story homes or commercial spaces.

These advanced adhesives also act as an anti-fracture membrane. Concrete subfloors naturally develop hairline cracks over time. A quality adhesive can bridge these minor cracks (typically up to 1/8 inch), creating a flexible layer that prevents them from transferring to your flooring. This is particularly useful with engineered wood with underfloor heating, where temperature changes can stress the subfloor.

Common Issues from the Wrong Engineered Wood Floor Adhesive

Using the wrong adhesive or poor application can lead to significant problems that often require costly repairs:

- Floor cupping or buckling: Occurs when the adhesive cannot handle moisture or accommodate the wood’s natural movement.

- Hollow spots: Caused by insufficient adhesive coverage, creating a hollow sound and compromising stability.

- Adhesive failure: A complete breakdown of the bond, leading to loose planks and widespread squeaking.

- Gaps between planks: Develop when the bond is not strong enough to hold planks tightly together.

- Sticky residue on the floor surface: Results from improper cleanup or incorrect curing, creating a messy surface that attracts dirt.

Understanding Adhesive Warranties

Adhesive warranties are your safety net, but they have conditions. Most manufacturers offer limited bond warranties (e.g., 10 years to lifetime) that cover the adhesive’s performance under normal, specified conditions. Some offer lifetime warranties for installations by certified professionals, reflecting the importance of proper application.

These warranties typically cover manufacturing defects but exclude issues from improper subfloor preparation, incorrect application, or environmental factors exceeding the product’s limits. As detailed in manufacturer warranty documents, following instructions is critical.

Professional installation is often required for warranty validity. Factors like trowel size, spreading technique, and curing conditions all determine performance. An expert installation ensures your warranty remains valid, protecting your investment for the long term.

Frequently Asked Questions about Engineered Wood Adhesives

Should engineered wood flooring be glued down?

While floating floors are an option, a glue-down installation is often the superior choice. It offers superior stability and a solid, premium feel underfoot, eliminating the “bouncy” feel of floating floors. The adhesive also provides significant sound dampening, reducing footfall noise. We especially recommend glue-down for installations over concrete, as an adhesive with a moisture barrier simplifies the process and provides robust protection. For high-traffic areas, the durability of a glued-down floor is best. For the best way to install engineered hardwood flooring on concrete slab, glue-down is the professional standard.

How much adhesive do I need for my engineered wood floor?

Calculating your need for Engineered Wood Floor Adhesive depends on three main factors: the adhesive type, your subfloor’s porosity (porous surfaces absorb more), and the trowel size. A larger-notched trowel applies more adhesive, reducing the coverage per gallon. For example, an adhesive might cover up to 55 sq. ft. per gallon, but this is an estimate. Always check the manufacturer’s specifications and use their recommended trowel to ensure a proper bond and avoid running short or over-purchasing. It’s wise to add a small buffer for waste.

Can you use the same adhesive for solid and engineered hardwood?

Sometimes, but you should never assume so. While some high-performance adhesives are rated for both, many are specific to one type. Engineered wood is dimensionally stable due to its layered construction and works with a wider range of adhesives. Solid hardwood expands and contracts more significantly with humidity changes and requires a robust, elastic adhesive designed to handle this movement. Using an adhesive not rated for solid wood can lead to bond failure. Conversely, using a solid wood adhesive on engineered flooring may be overkill. Always verify that the adhesive is recommended for your specific flooring type by both the flooring and adhesive manufacturers, especially when gluing solid hardwood floors to concrete.

Conclusion

Choosing the right Engineered Wood Floor Adhesive is a critical step in ensuring your floor’s beauty and longevity. As we’ve covered, the ideal choice depends on your subfloor, moisture conditions, and performance needs, with options ranging from polyurethane to acrylic latex and advanced SMPs.

A quality adhesive is an investment. It provides stability, dampens sound, resists moisture, and accommodates the wood’s natural movement. However, even the best product will fail without proper subfloor preparation. A clean, level, and dry subfloor is non-negotiable for a lasting installation.

While DIY is an option, the complexities of adhesive selection, application, and curing often require professional expertise to avoid costly mistakes like cupping, hollow spots, or voided warranties.

For expert Engineered Wood Floor Adhesive selection and flawless installation in the Revere, MA area, trust Romero Hardwood Floors Inc. Since 2006, our team has provided guaranteed workmanship and competitive pricing. Let our 15+ years of experience ensure you get a beautiful, durable floor that improves your property’s value for years to come.